Special fertilizer for sugarcane and preparation method of fertilizer

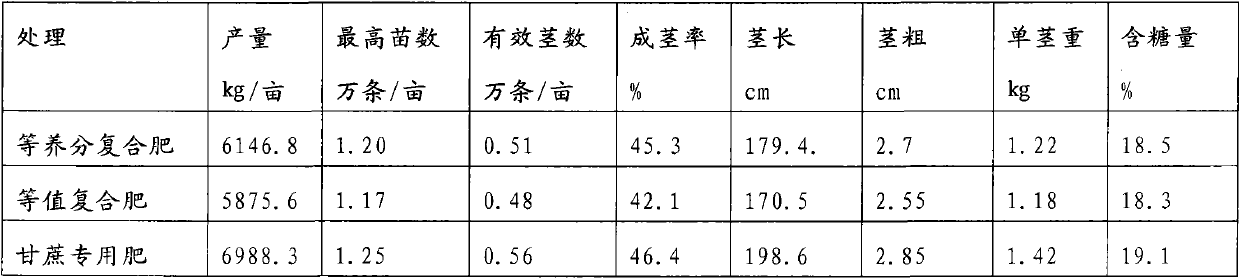

A special fertilizer and technology for sugarcane, which is applied in the field of special fertilizer for sugarcane and its preparation, can solve the problems of non-energy saving and environmental protection, low fertilizer utilization rate, etc., and achieve the effect of improving product performance, reducing the amount of chemical fertilizer, and good taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] The formula in parts by weight is: 440 kg of molten urea, 20 kg of humic acid, 145 kg of monoammonium phosphate, 45 kg of potassium chloride, 270 catties of potassium sulfate, 62 kg of dolomite powder, 3 kg of magnesium sulfate, 2 kg of zinc sulfate, poly 3 kg of aspartic acid.

[0018] The specific production process is as follows: 440 kg of molten urea from the urea production unit is transported to reactor A through the molten urea pump, mixed with 270 kg of potassium sulfate, 45 kg of potassium chloride, 62 kg of dolomite powder, and mixed with the system return material, heated and stirred, and the stirring speed 130 rpm, temperature 115-118°C, stirring time 3 minutes; the flow of urea is measured by a mass flow meter, and then flows into the reactor A, and the potassium sulfate, potassium chloride, and dolomite powder that have been metered and transported according to the ratio are in the reactor A. Internal mixing, heating and stirring; 3 kg of polyaspartic acid,...

Embodiment 2

[0020] The formula in parts by weight is: 400 kg of molten urea, 30 kg of humic acid, 130 kg of monoammonium phosphate, 30 kg of potassium chloride, 250 catties of potassium sulfate, 58 kg of dolomite powder, 2 kg of magnesium sulfate, 1 kg of zinc sulfate, Aspartic acid 2.5 kg.

[0021] The specific production process is as follows: 400 kg of molten urea from the urea production unit is transported to reactor A through the molten urea pump, mixed with 250 kg of potassium sulfate, 30 kg of potassium chloride, 58 kg of dolomite powder, and mixed with the system return material, heated and stirred, and the stirring speed 130 rpm, temperature 115-118°C, stirring time 3 minutes; the flow of urea is measured by a mass flow meter, and then flows into the reactor A, and the potassium sulfate, potassium chloride, and dolomite powder that have been metered and transported according to the ratio are in the reactor A. Internal mixing, heating and stirring; 2.5 kg of polyaspartic acid, 1 k...

Embodiment 3

[0023] The formula in parts by weight is: 430 kg of molten urea, 10 kg of humic acid, 100 kg of monoammonium phosphate, 40 kg of potassium chloride, 200 catties of potassium sulfate, 55 kg of dolomite powder, 2.5 kg of magnesium sulfate, 1.8 kg of zinc sulfate, poly Aspartic acid 2 kg.

[0024] The specific production process is as follows: 430 kg of molten urea from the urea production unit is transported to reactor A through a molten urea pump, mixed with 200 kg of potassium sulfate, 40 kg of potassium chloride, 55 kg of dolomite powder, and mixed with the system return material, heated and stirred, and the stirring speed 130 rpm, temperature 115-118°C, stirring time 3 minutes; the flow of urea is measured by a mass flow meter, and then flows into the reactor A, and the potassium sulfate, potassium chloride, and dolomite powder that have been metered and transported according to the ratio are in the reactor A. Internal mixing, heating and stirring; Stir and chelate 2 kg of po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com