Large-sized high purity tungsten target and production method thereof

A production method and large-scale technology, applied in metal material coating process, ion implantation plating, coating, etc., can solve the problems of stainless steel sleeve deformation, complex production process, and not suitable for mass industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

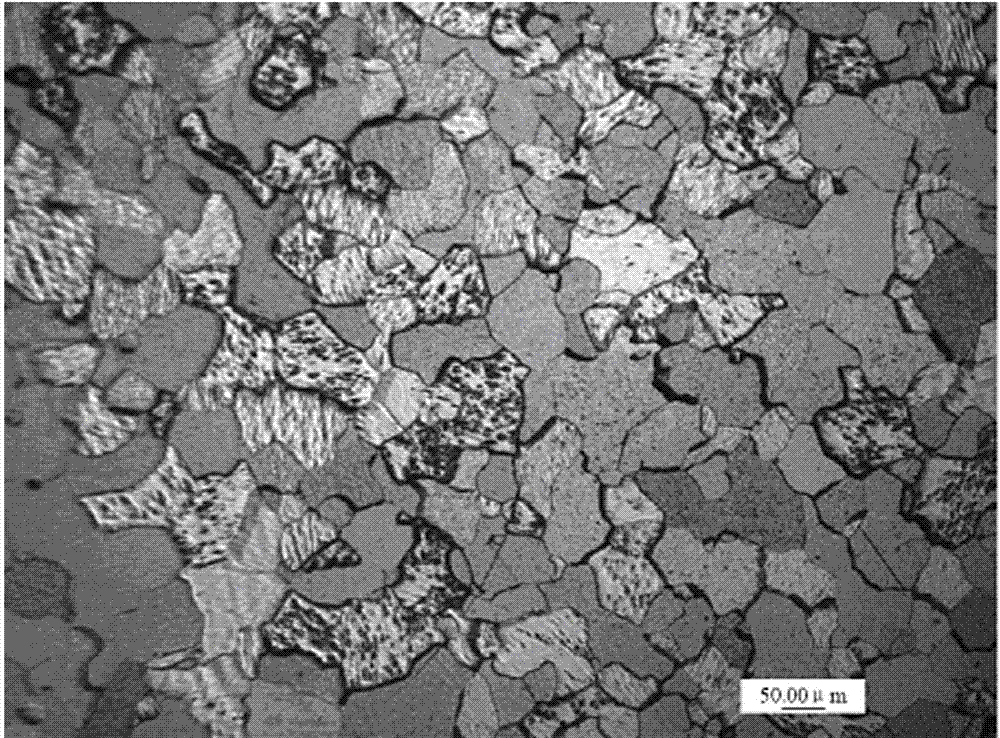

[0019] Example 1: Select 38.1 kg of tungsten powder with a particle size of 2.45 μm and a purity of 99.999%, and use a steel core mold to press and hold the pressure at 200 MPa for 5 minutes before forming; sintering in an intermediate frequency furnace, the sintering temperature is 2350 ° C, and the sintering time is 10 hour, the prepared size is 47.3×201×218mm, the density is 18.4g / cm 3 sintered tungsten slabs; tungsten slabs are annealed at 1500°C / 90min, and hot-rolled through multiple passes to a size of 11.1×425×419mm and a density of 19.27g / cm 3 (density 99.6%) hot-rolled tungsten plate, the total hot-rolled deformation is 76.5%; after the hot-rolled tungsten plate is annealed at 1350°C / 120min, it is machined by turning, milling, and grinding. The processing volume is 1.9mm and 2.2mm respectively; the tungsten target material of Φ400±0.1×7±0.1mm is finally processed, and the average grain size of the surface is measured to be 64μm, and the surface grain structure is as f...

Embodiment 2

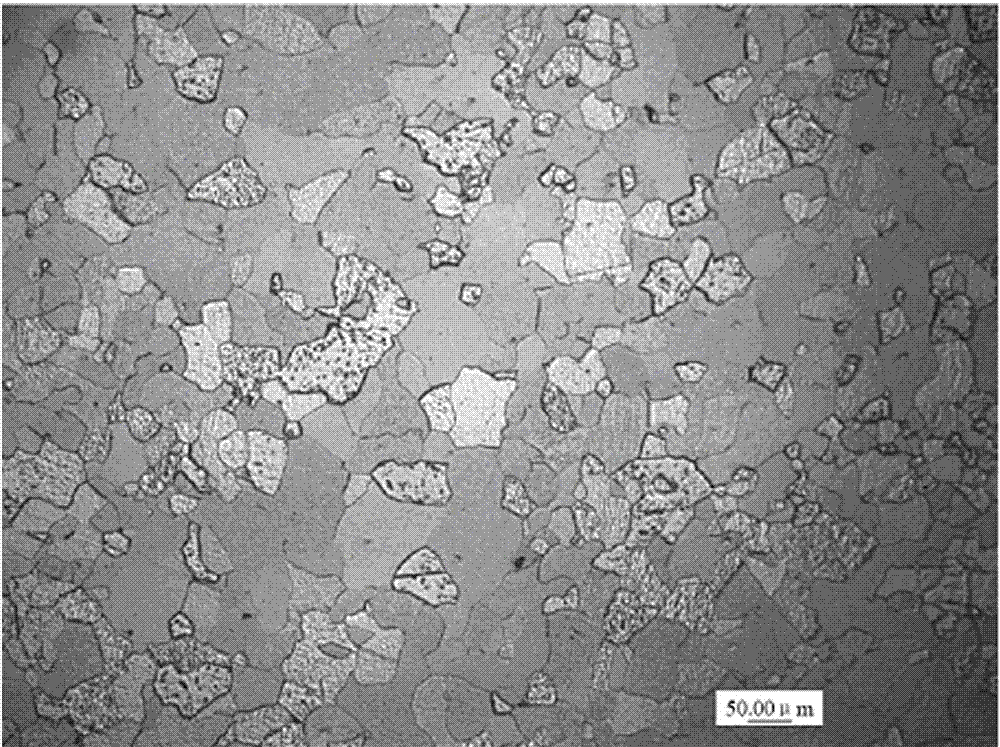

[0020] Example 2: Select 54.5 kg of tungsten powder with a particle size of 2.6 μm and a purity of 99.999%, and use a steel core mold to press isostatically press at 250 MPa for 8 minutes and then form it; sinter in an intermediate frequency furnace, the sintering temperature is 2400 ° C, and the sintering time is 8 Hours, the prepared size is 60.7×223×219mm, the density is 18.4g / cm 3 The sintered tungsten slab; after the tungsten slab is annealed at 1550℃ / 120min, it is hot-rolled through multiple passes to a size of 12.3×476×483mm and a density of 19.28g / cm 3 (Density 99.6%) hot-rolled tungsten plate, the total deformation of hot-rolled is 79.7%; after the hot-rolled tungsten plate is annealed at 1400℃ / 90min, it is machined by turning, milling, grinding, etc., the mechanical processing of the upper and lower surfaces The processing volume is 2.1mm and 2.2mm respectively; the Φ450±0.1×8±0.1mm tungsten target is finally processed. After measurement, the average grain size of th...

Embodiment 3

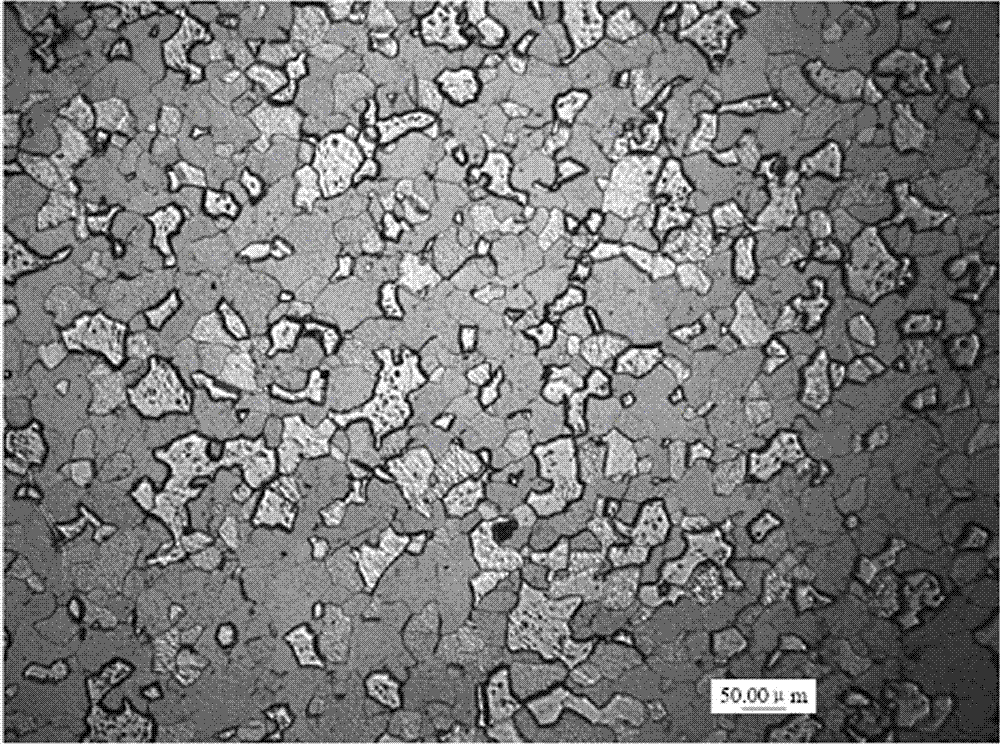

[0021] Example 3: Select 64.3 kg of tungsten powder with a particle size of 2.2 μm and a purity of 99.999%, and use a steel core mold to press and hold the pressure at 180 MPa for 10 minutes before forming; sintering in an intermediate frequency furnace, the sintering temperature is 2300 ° C, and the sintering time is 12 Hours, the prepared size is 64.3×235×230mm, the density is 18.5g / cm 3 sintered tungsten slabs; tungsten slabs are annealed at 1450°C / 180min, and hot-rolled through multiple passes to a size of 12.1×527×521mm and a density of 19.30g / cm 3 (density 99.7%) hot-rolled tungsten plate, the total hot-rolled deformation is 81.2%; after the hot-rolled tungsten plate is annealed at 1300°C / 150min, it is machined by turning, milling, and grinding. The processing amount is 2.0mm and 2.1mm respectively; Φ500±0.1×8±0.1mm tungsten target is finally processed, and the average grain size of the surface is measured to be 47μm, and the surface grain structure is as follows: imag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com