A method for preparing fluorescent nanofibers based on photografting surface modification

A surface modification and nanofiber technology, applied in the direction of fiber type, fiber treatment, chemical instruments and methods, etc., can solve the problem of low fluorescence activity, and achieve the effect of simple preparation process, strong repeatability and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

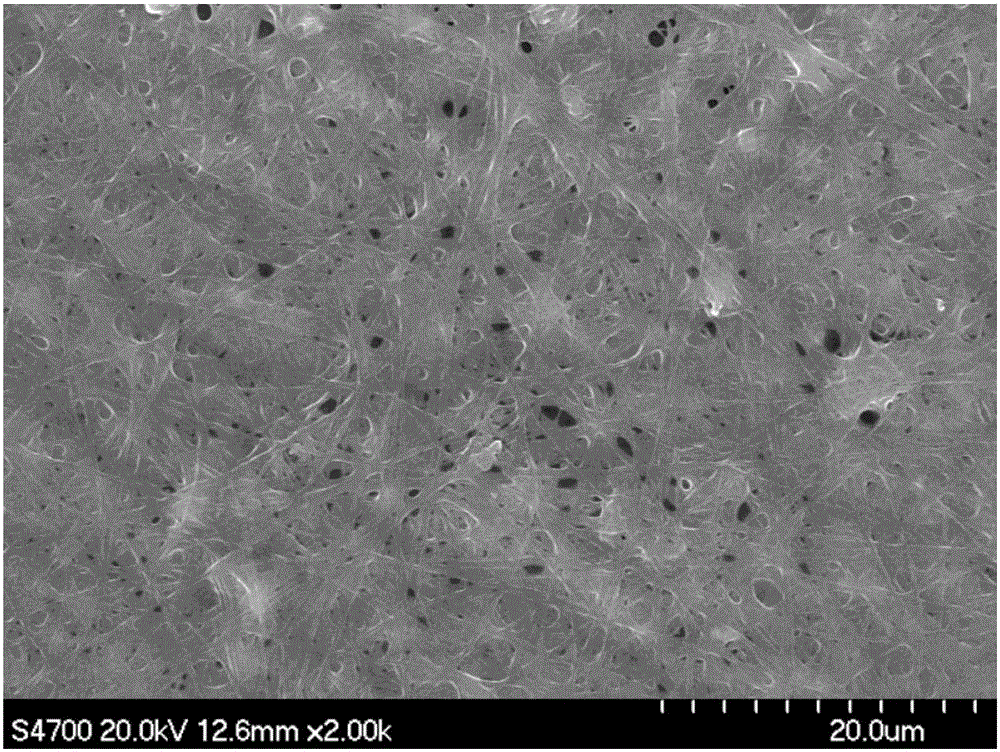

Image

Examples

Embodiment 1

[0020] 1) Dissolve 7.2g (0.1mol) of acrylic acid and 22.4g (0.1mol) of dibenzoylmethane in 100ml of DMF in a 250ml four-necked flask, and adjust the pH value within the range of 6-7. Dissolve 16.8g (0.05mol) of europium nitrate in 100ml of DMF, and slowly add it dropwise into a four-neck flask, control the temperature at 40°C, and complete the dropwise addition in 30 minutes; after the dropwise addition, keep the temperature at 60°C for 48h. Precipitate with ethanol as a precipitant, filter the precipitate, wash with distilled water and ethanol, and dry in vacuum at a constant temperature to obtain an organic complex europium ion fluorescent material;

[0021] 2) Prepare a DMF solution of 10wt% PAN, dissolve 1-hydroxycyclohexyl phenyl ketone (184) in the DMF solution of PAN, and adjust suitable electrospinning spinning conditions to prepare photosensitive nanofibers;

[0022] 3) Dissolve 3 g of the europium ion fluorescent ligand prepared in step 1) in 10 ml of chloroform, and...

Embodiment 2

[0024] 1) Dissolve 3.6g (0.05mol) of acrylic acid and 33.6g (0.15mol) of dibenzoylmethane in 100ml of DMF in a 250ml four-necked flask, and adjust the pH value within the range of 6-7. Dissolve 16.8g (0.05mol) of europium nitrate in 100ml of DMF, and slowly add it dropwise into a four-neck flask, control the temperature at 40°C, and complete the dropwise addition in 30 minutes; after the dropwise addition, keep the temperature at 60°C for 48h. Precipitate with ethanol as a precipitant, filter the precipitate, wash with distilled water and ethanol, and dry in vacuum at a constant temperature to obtain an organic complex europium ion fluorescent material;

[0025] 2) Prepare a DMF solution of 10wt% PAN, dissolve 2-hydroxy-2-methyl-phenylacetone-1 (1173) in the DMF solution of PAN, and adjust the appropriate electrospinning spinning conditions to prepare photosensitive nanofibers;

[0026] 3) Dissolve 4 g of the europium ion fluorescent ligand prepared in step 1) in 10 ml of chlo...

Embodiment 3

[0028] 1) Dissolve 7.2g (0.1mol) of acrylic acid and 22.4g (0.1mol) of dibenzoylmethane in 100ml of DMF in a 250ml four-necked flask, and adjust the pH value within the range of 6-7. Dissolve 33.6g (0.1mol) of europium nitrate in 100ml of DMF, and slowly drop it into a four-neck flask, control the temperature at 40°C, and complete the dropwise addition in 30 minutes; after the dropwise addition, keep the temperature at 60°C for 48h. Precipitate with ethanol as a precipitant, filter the precipitate, wash with distilled water and ethanol, and dry in vacuum at a constant temperature to obtain an organic complex europium ion fluorescent material;

[0029] 2) Prepare a DMF solution of 10wt% PAN, dissolve 2-methyl-1-(4-methylmercaptophenyl)-2-morphineacetone-1 (907) in the DMF solution of PAN, and adjust the electrospinning spinning Preparation of photosensitive nanofibers under silk conditions;

[0030] 3) Dissolve 5 g of the europium ion fluorescent ligand prepared in step 1) in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com