System for cycling power generation by means of supercritical CO2 working medium

A technology of working medium circulation and power generation system, which is applied in the direction of machines/engines, energy-saving heating/cooling, lighting and heating equipment, etc., can solve environmental pollution and other problems, achieve the effect of increasing system output power and reducing cold end loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

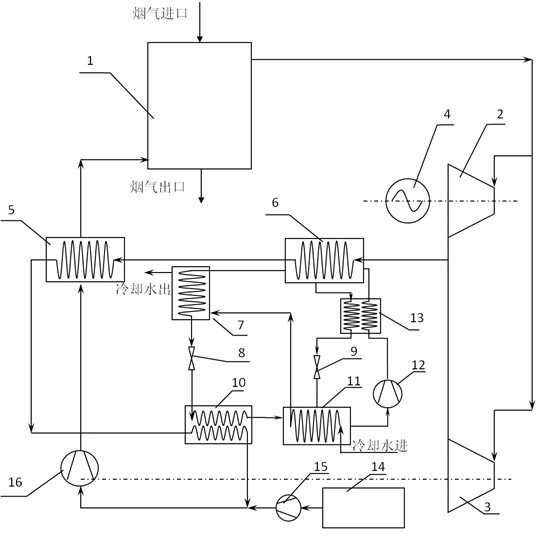

Method used

Image

Examples

Embodiment 2

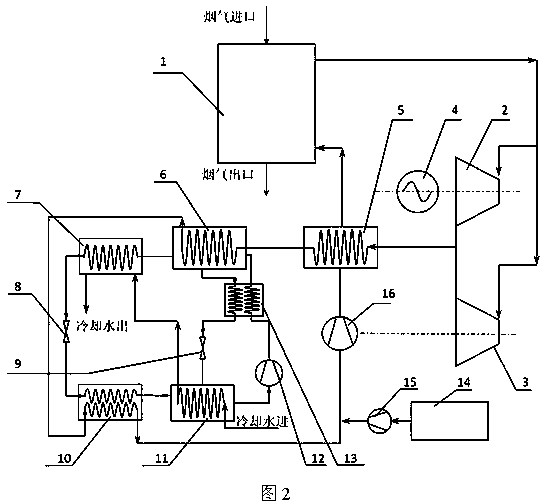

[0037] Example 2, such as figure 2 As shown, the difference from Embodiment 1 is that the regenerator 5 is arranged between the outlet of the first turbine, the outlet of the second turbine and the inlet of the generator. High temperature CO at turbine outlet 2 The working fluid is first to the low-temperature CO at the outlet of the first circulating pump 2 The working fluid is heated and then sent to the absorption refrigeration system for further heat release.

Embodiment 3

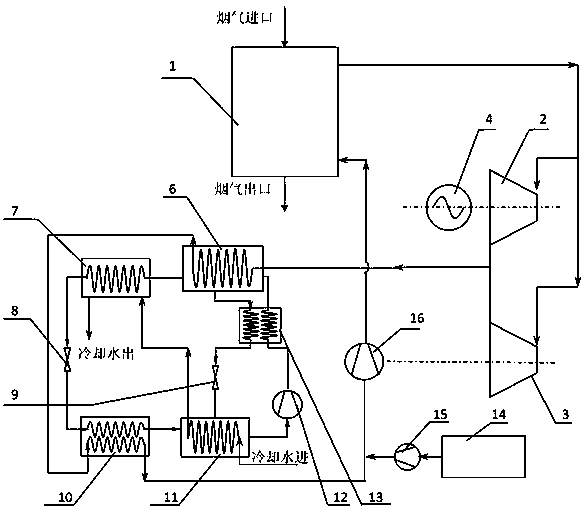

[0038] Example 3, such as image 3 As shown, the regenerator in the system is cancelled, and the high-temperature CO at the outlet of the first turbine and the second turbine is 2 The working fluid is directly sent to the absorption refrigeration system for heat release.

[0039] Specifically, the inlet of the waste heat boiler 1 is connected to the first circulating pump 16, the outlet is connected to the inlets of the first turbine 2 and the second turbine 3 respectively, and the outlets of the first turbine 2 and the second turbine 3 are connected to the absorption refrigeration system. The tube-side inlet of the generator 6 in the system, the first turbine 2 is used to drive the generator 4 to generate electricity, and the second turbine 3 is used to drive the first circulation pump 16, wherein the tube-side outlet of the generator 6 is connected to the evaporator 10 is connected to the second inlet, and the bottom of the generator 6 is provided with a liquid dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com