One-hydraulic-motor double-loop control system

一种液压马达、控制系统的技术,应用在流体压力致动系统组件、伺服马达、传动装置控制等方向

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

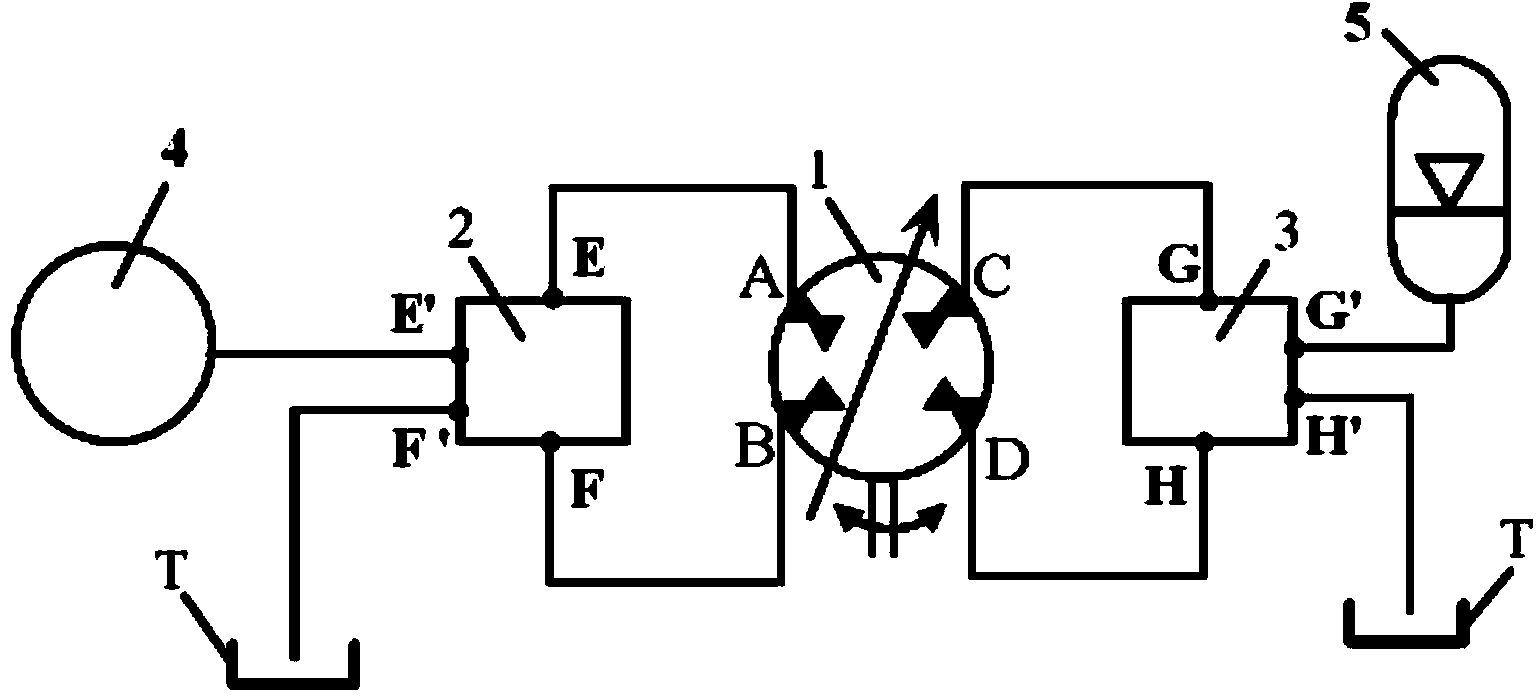

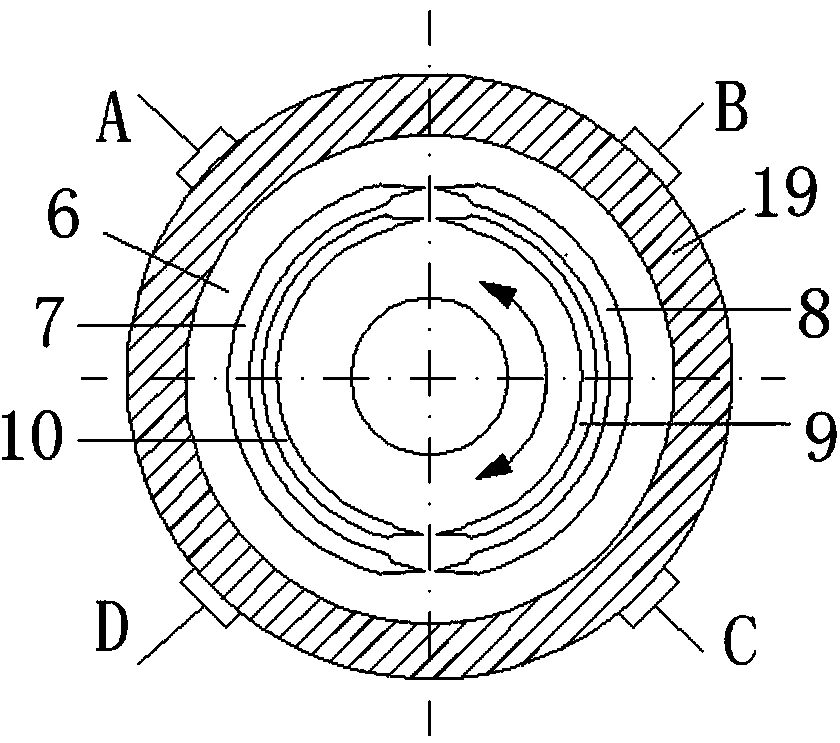

[0033] Such as Figure 4 As shown, the active control loop 2 of the single hydraulic motor dual-loop control system in this embodiment adopts an open loop with independent control of inlet and outlet, and the passive control loop 3 adopts an open loop controlled by a proportional directional valve, wherein the active control loop 2 Including the I, II, III pressure sensors 27, 28, 34, the I, II, III, IV two-position two-way proportional throttle valves 29, 30, 32, 33, and the I overflow Valve 31; passive control circuit 3 includes first and second one-way valves 36, 37 and electromagnetic proportional directional valve 35;

[0034] The first working oil port E of the active control circuit is connected with the first oil inlet and outlet A of the hydraulic motor 1, and the second working oil port F of the active control circuit is connected with the second oil inlet and outlet B of the hydraulic motor 1; passive control The third working oil port G of the circuit is connected...

Embodiment 2

[0039] Such as Figure 5 As shown, the active control loop 2 of the single hydraulic motor dual loop control system in this embodiment adopts a closed loop controlled by a hydraulic pump, and the passive control loop is an open loop controlled by a proportional directional valve. Among them, the active control circuit 2 includes the first, second and third relief valves 31, 41 and 42, the first and second one-way valves 36 and 37, the second V two-position two-way proportional throttle valve 44 and the charge pump 43. The passive control circuit 3 includes an electromagnetic proportional directional valve 35; the hydraulic pump 4 is a two-way variable pump, powered by a power source 39, and the power source 39 is an internal combustion engine or an electric motor with a constant speed;

[0040] The first working oil port E and the second working oil port F of the active control circuit are respectively connected with the first oil inlet and outlet port A and the second oil inl...

Embodiment 3

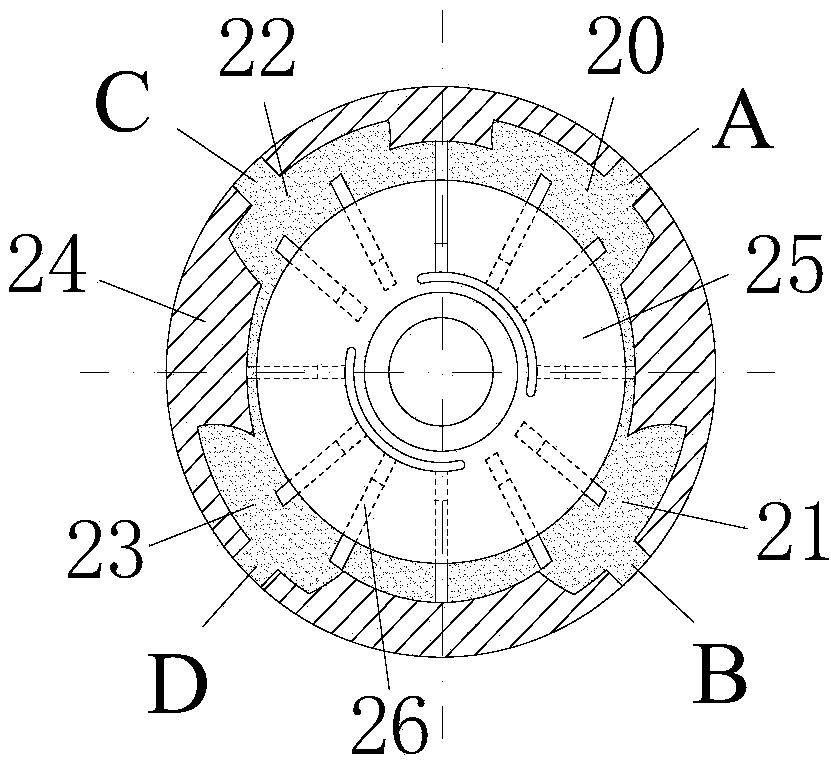

[0045] Such as Image 6 As shown, the hydraulic pump 4 is a quantitative hydraulic pump, and the power source 39 is an electric motor with adjustable speed, which can be an AC asynchronous motor, an AC or DC servo motor or a switched reluctance motor, etc., and has a speed control device.

[0046] In the single hydraulic motor dual-loop control system in this embodiment, the closed loop controlled by the hydraulic pump in the active control loop is the same as the active control loop in Embodiment 2, and the passive control loop 3 adopts an open loop with independent control of inlet and outlet and oil ports. It is the same as the active control loop in Embodiment 1.

[0047] The connection mode between the active control circuit and the hydraulic motor is the same as the connection mode between the active control circuit and the hydraulic motor in Embodiment 2; the third working oil port G and the fourth working oil port H of the passive control circuit are respectively conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com