Electronic filter device and method of oil products in hydraulic and lubrication field

A filter and electronic filter element technology, which is applied in chemical instruments and methods, fluid pressure actuation devices, lubricating parts, etc. The effect of reducing the number of maintenance, reducing the number of maintenance, and reducing the frequency of oil changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

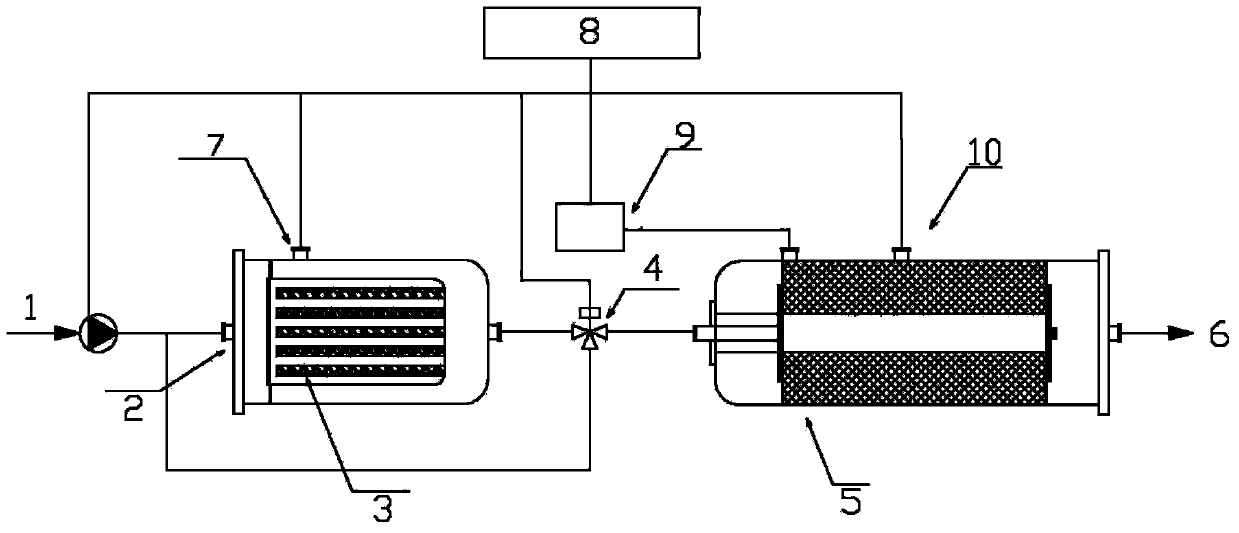

[0032] Such as figure 1 Shown is a structural diagram of the device of the present invention, including a pump 2, a control system 8, a high-voltage electrostatic generator 9, an electronic filter element device 5, a high-density fiber water absorption filter device 3, a pressure sensor 10, a moisture sensor 7, and an oil tank outlet pipeline 1 is connected to the inlet end of the high-density fiber water-absorbing filter device 3 through the pump 2, and the high-density fiber water-absorbing filter device 3 is connected to the inlet end of the left side of the high-voltage electronic filter device 5 through the solenoid valve 4, and the right side of the high-voltage electronic filter device 5 The outlet end of the hydraulic system is connected to the inlet pipe 6 of the oil tank of the hydraulic system, and the other pipeline of the solenoid valve 4 is connected to the oil discharge pipe of the pump 2. The control system 8 controls the pump 2, solenoid valve 4, high-voltage e...

Embodiment 2

[0040] Shanghai Solid Foundation Company installed this device in its 800-ton static pressure pile foundation in June 2012. Its hydraulic oil has been reduced from NAS10 to NAS7 and is stable at NAS7. The oil that needs to be replaced immediately has been used so far. For more than a year, the hydraulic system has not had any failures, the production efficiency has been greatly improved, and the entire equipment has achieved the effect of new equipment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com