Ammonia torch burner

A technology of torch combustion and ammonia gas, applied in the direction of burners, gas fuel burners, combustion methods, etc., can solve the problems of head corrosion resistance, poor high temperature resistance, poor mixing degree, high maintenance cost, etc., and increase the service life , ensure full combustion, and avoid environmental problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to facilitate the understanding of the technical content of the present invention, the technical solutions of the present invention will be further described below in conjunction with the accompanying drawings.

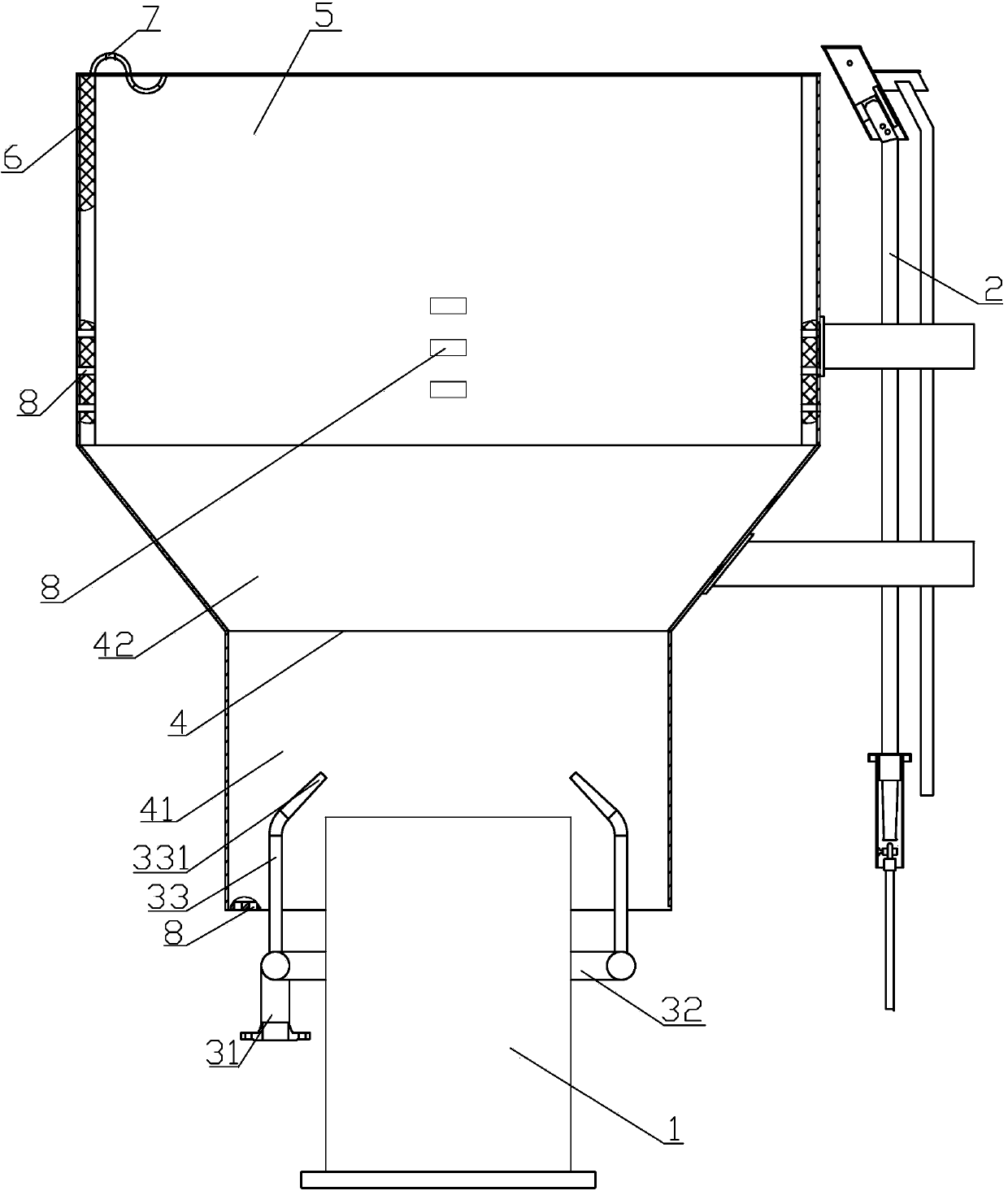

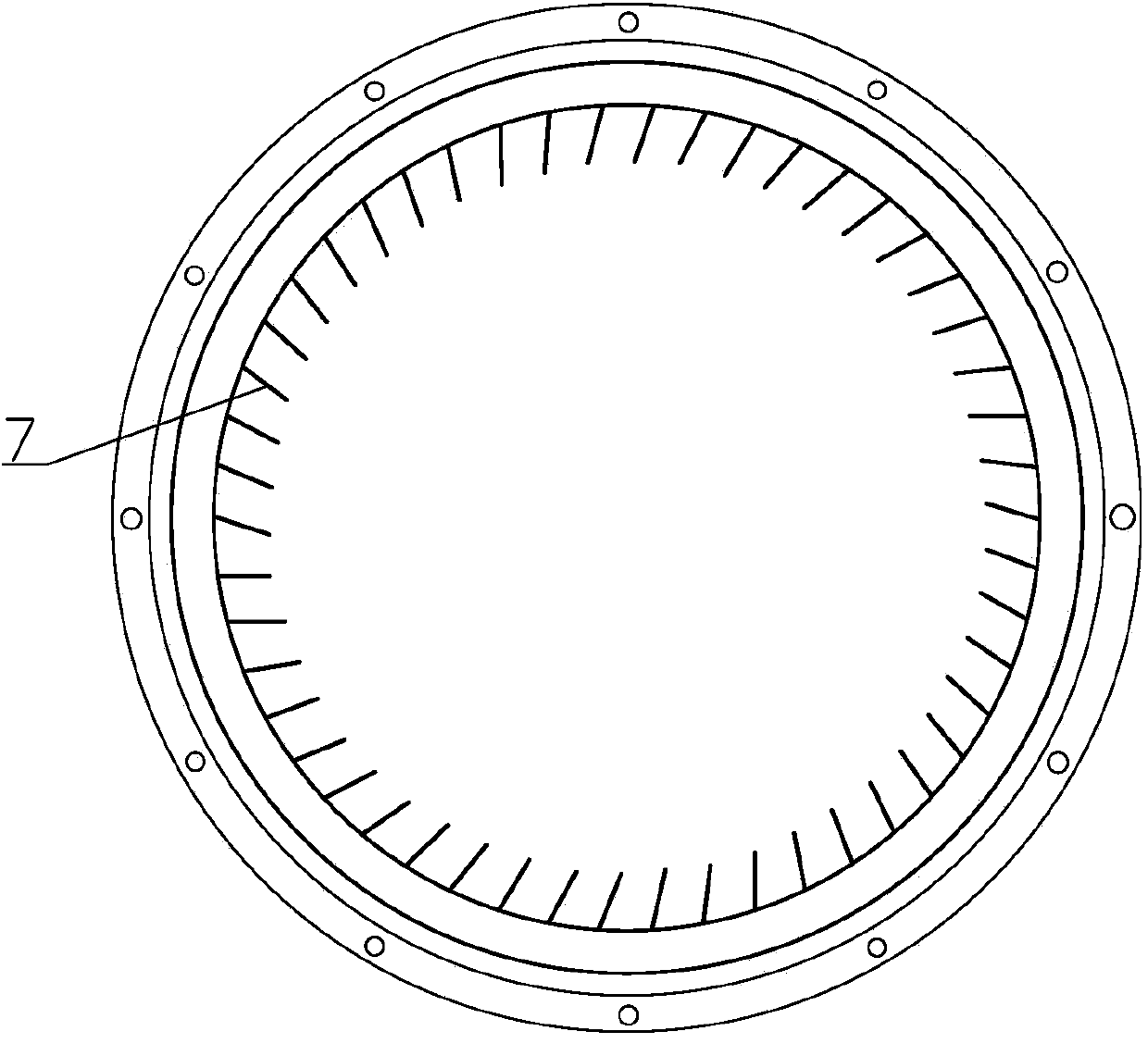

[0019] Such as figure 1 and figure 2 As shown, an ammonia gas torch burner includes an air intake cylinder 1 , an ignition lamp assembly 2 , a fuel gas delivery part, a premixing chamber 4 and a combustion chamber 5 . The intake cylinder 1, the premix chamber 4 and the combustion chamber 5 are coaxially arranged.

[0020] The pre-mixing chamber 4 includes a mixing chamber 41 and an enlarged diameter chamber 42 arranged at the upper end of the mixing chamber 41 and communicating with it. The mixing chamber 41 and the expanding diameter chamber 42 are also arranged coaxially. When the gas enters the diameter-expanding chamber 42 from the mixing chamber 41, the flow velocity slows down and begins to diffuse, which can further ensure the mixing uniform...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com