Building foundation sand heat storage self-heating system

A heating system and ground-based technology, applied in the field of HVAC, can solve the problems of mismatching needs, energy consumption, poor controllability of heat release process, etc., to reduce insulation and moisture-proof costs, reduce construction and installation costs, and reduce repeated construction costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

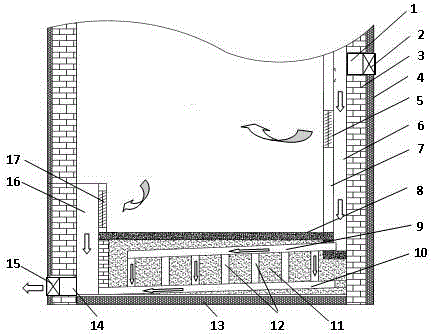

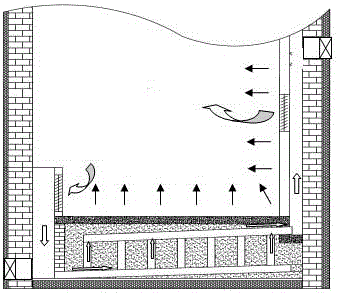

[0020] Such as figure 1 , Figure 11 As shown, a building foundation type sand heat storage self-heating system, which includes a house foundation and a wall 3, and also includes a foundation type sand heat storage self-heating system, which is located on the inner side of two opposite or adjacent wall 3 and is far away from the wall 3 A first partition 7 and a second partition 21 are built at a distance of 1 cm to 50 cm. The space surrounded by the first partition 7 and the enclosure wall 3 constitutes the hot air duct 6 , and the space enclosed by the second partition 21 and the enclosure wall 3 constitutes a The cold air duct 16 is provided with an air inlet 1 on the enclosure wall 3 or the top floor 18 forming the hot air duct 6, and a first valve or a baffle 2 is arranged in each air inlet 1, and the cold air duct 16 is formed Open the air outlet 14 on the surrounding wall 3 or the top floor 18, in each air outlet 14 is provided with a second valve or baffle plate 15, th...

Embodiment 2

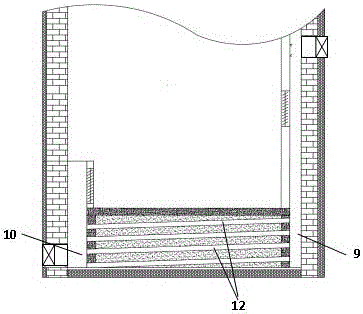

[0034] On the basis of Example 1, the figure 1 , figure 2 The heat exchange tube 12 in the horizontal placement, such as image 3 As shown, the upper diffuser 9 and the lower diffuser 10 are respectively connected to the two ends of the heat exchange tube 12, wherein the upper diffuser 9 communicates with the hot air duct 6, and the lower diffuser 10 communicates with the cold air duct 16 and the outlet. The wind holes 14 communicate with each other. It should be noted that this way of laying the heat exchange tubes horizontally and placing the diffuser vertically has a simple structure, convenient installation, and small air flow resistance, but it is not conducive to heat transfer from the heat storage body in the lower layer to the ground layer. The heat transfer power from the floor to the house is small, so the total heat transfer power of the system is small, and the temperature of the underground heat storage body required is relatively high.

Embodiment 3

[0036] On the basis of Example 1 and Example 2, the figure 2 , image 3 The upper diffuser 9 and the lower diffuser 10 in the Figure 4 Plate diffuser shown. What needs to be explained is that the flow resistance of the plate diffuser is small, and the effect of diverging and converging is good, but the construction process is more complicated, the construction cost is higher, and the overall effect is better.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com