Method for testing influence on corrosion inhibition performance of corrosion inhibitor caused by pH value

A test method and technology for corrosion inhibitors, which can be applied in the direction of removing certain components and weighing, etc., can solve problems such as pitting corrosion and corrosion, and achieve the effects of accurate test results, simple test steps and low test costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

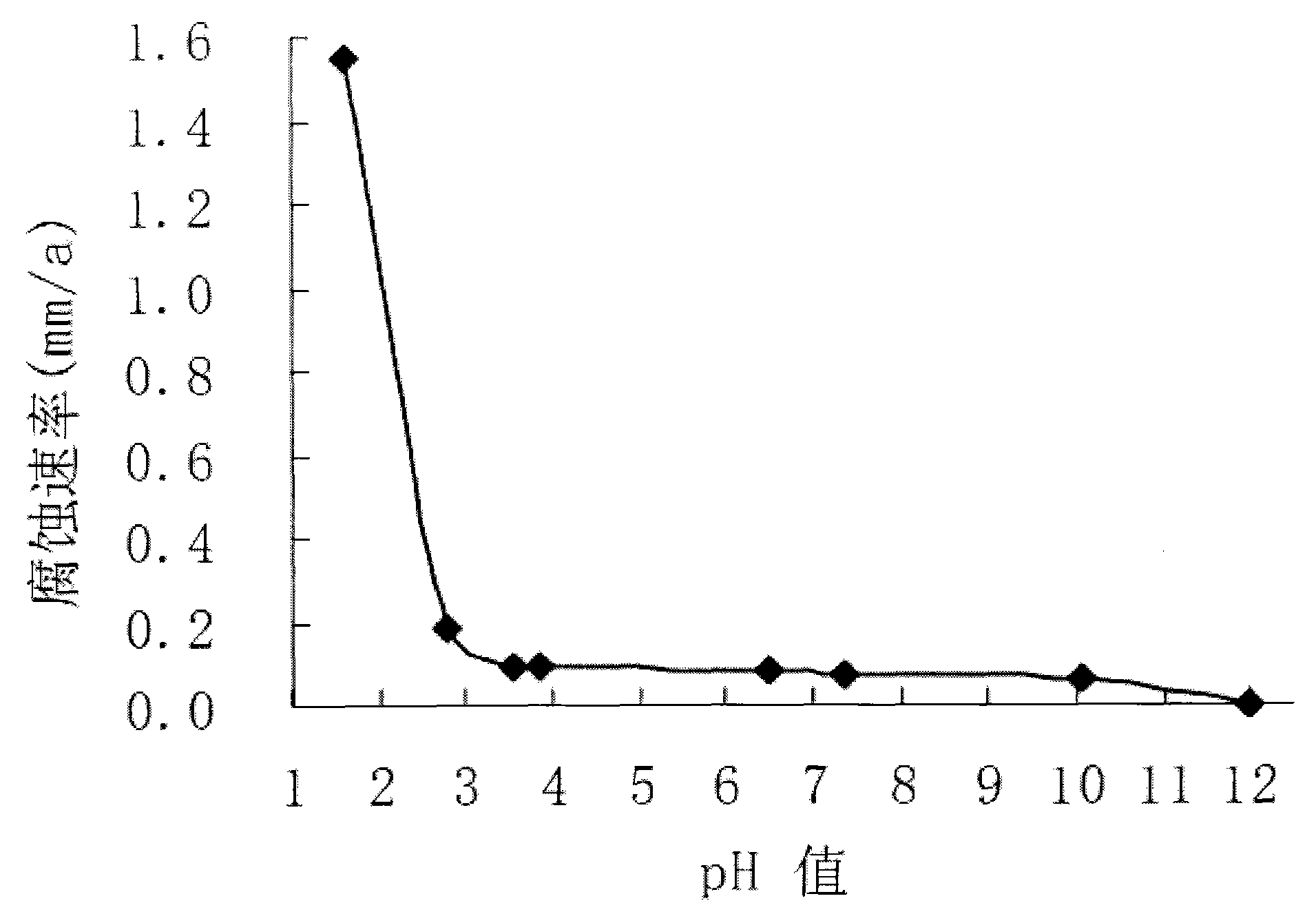

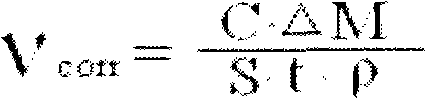

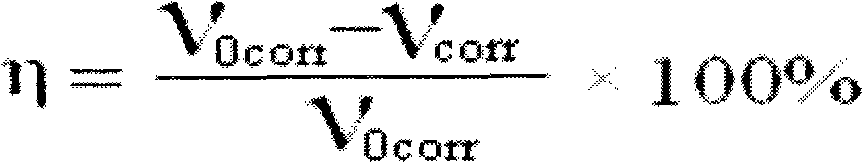

[0038] The invention relates to a method for testing the corrosion inhibition performance of a corrosion inhibitor affected by the pH value, comprising: processing petroleum pipes into experimental test pieces according to the specified size, and then packing them separately after soaking; Put it into a container filled with petroleum ether, remove the dirt on the surface of the test piece with absorbent cotton, and wash it twice continuously; polish the test piece, measure the size of the test piece, and record the data in order; scrub and dry the test piece, and put Put it into a desiccator to dry, weigh to constant weight, and write down the data; hang the test piece in the corrosion inhibitor, and adjust the pH value of the corrosion inhibitor to 1.0-12.0, and the corrosion reaction takes a certain time; take out the test piece Rinse, soak it in rust remover, wash it with a silk brush dipped in a little decontamination powder; dry the test piece with a cloth, then wipe it w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Boiling range | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com