Preparation method of lithium iron phosphate/carbon nanotube composite material

A technology of carbon nanotubes and lithium iron phosphate, applied in electrical components, battery electrodes, circuits, etc., can solve the problems of uneven carbon coating and low tap density, and achieve uniform carbon coating and tap density High, uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] A preparation method of a lithium iron phosphate / carbon nanotube composite material, the preparation method sequentially includes a slurry preparation process, a slurry drying process, and a sintering process of a precursor powder, and the slurry contains carbon nanotubes;

[0064] The preparation process of the slurry: first stir the water-based carbon nanotube dispersion (the mass percentage concentration of carbon nanotubes is less than or equal to 10%) in a mixer to make the carbon nanotube dispersion change from a solidified state to a liquid state, and then to the carbon nanotube Add lithium source, iron source, phosphate, carbon source, water and stir to form slurry in tube dispersion liquid, the solid content of this slurry is 70 wt.%; The addition amount of described lithium source, iron source, phosphate, carbon source The solid phase reaction forms lithium iron phosphate with a carbon content of 2–4 wt.% as a standard; the carbon nanotubes account for 1 wt.% o...

Embodiment 2

[0068] The basic content is the same as in Example 1, except that carbon nanotubes account for 0.5wt.% of the total mass of carbon nanotubes, lithium source, iron source, phosphate, and carbon source.

Embodiment 3

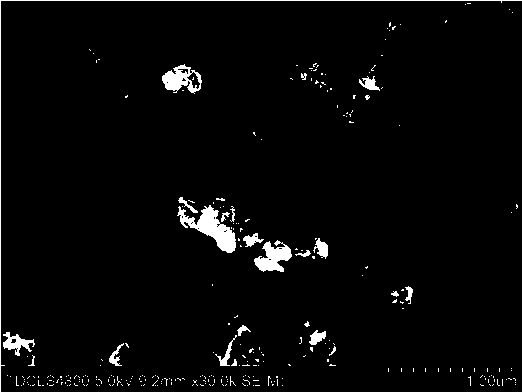

[0070] The basic content is the same as in Example 1, except that the solid content of the slurry is 50 wt.%, and carbon nanotubes account for 10wt.% of the total mass of carbon nanotubes, lithium source, iron source, phosphate, and carbon source ( figure 2 is a scanned image of the composite).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com