Method for preparing cocoa butter equivalent by using chemical transesterification method

A technology of cocoa butter and transesterification, applied in the directions of cocoa, application, food science, etc., can solve the problems of high cost, low yield of cocoa butter-like products, and no literature reports on preparation of cocoa butter-like butter, and achieves low cost and high yield. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

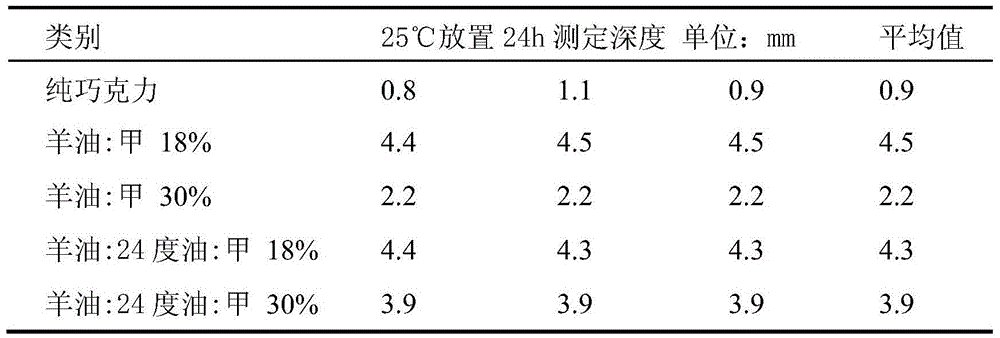

Embodiment 1

[0022] A method for preparing cocoa butter by chemical transesterification, comprising the following steps: taking suet oil and methyl stearate with a mass ratio of 90:10 and mixing them in a reaction Erlenmeyer flask; Dehydration and degassing under vacuum conditions of ~-0.1MPa for 30 minutes; then add high-efficiency catalyst sodium methoxide, maintain the above vacuum degree and perform esterification reaction at 90°C for 15 minutes; keep stirring, slowly add 10% of oil weight into the reaction bottle citric acid aqueous solution to terminate the reaction; then wash the reaction product with 95°C hot water for 3-4 times, and then filter to remove water to obtain the cocoa butter-like product.

[0023] A method for preparing cocoa butter by chemical transesterification, characterized in that the amount of sodium methoxide added is 0.8% of the weight of the above mixed oil.

[0024] A method for preparing cocoa butter by chemical transesterification, characterized in that th...

Embodiment 2

[0026] A kind of method that utilizes chemical transesterification method to prepare cocoa-like butter, comprises the following steps: get the suet oil, 24 degree palm oil and methyl stearate that take mass ratio and be 45:45:10 and mix and be placed in reaction Erlenmeyer flask, in 105~110℃, dehydration and degassing under vacuum conditions of -0.098~-0.1MPa for 30 minutes; then add high-efficiency catalyst sodium methoxide, maintain the above vacuum degree and perform esterification reaction at 90℃ for 15 minutes; keep stirring, pour into the reaction bottle Slowly add citric acid aqueous solution with 10% oil weight to stop the reaction; then wash the reaction product with 85°C hot water for 3-4 times, and filter to remove water to obtain the cocoa butter-like product.

[0027] A method for preparing cocoa butter by chemical transesterification, characterized in that the amount of sodium methoxide added is 0.5% of the weight of the above mixed oil.

[0028] A method for pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com