Laser-induced breakdown spectroscopic (LIBS) intelligent sorting method and apparatus for ore

A laser-induced breakdown and ore technology, which is applied in the direction of material excitation analysis, material analysis and sorting through optical means, can solve problems such as difficult to achieve trace and precise quantitative analysis, and achieve the effect of improving taste and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

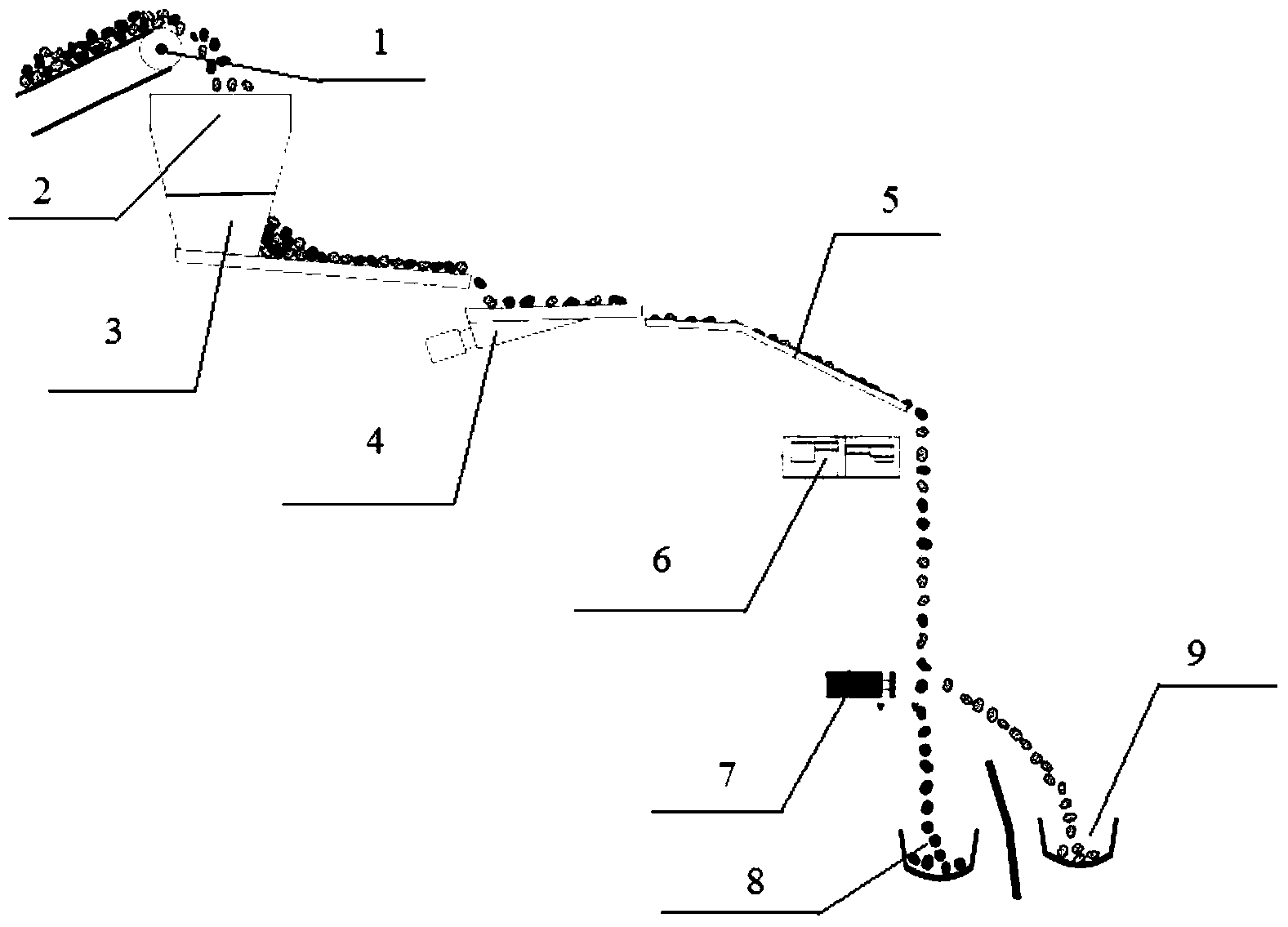

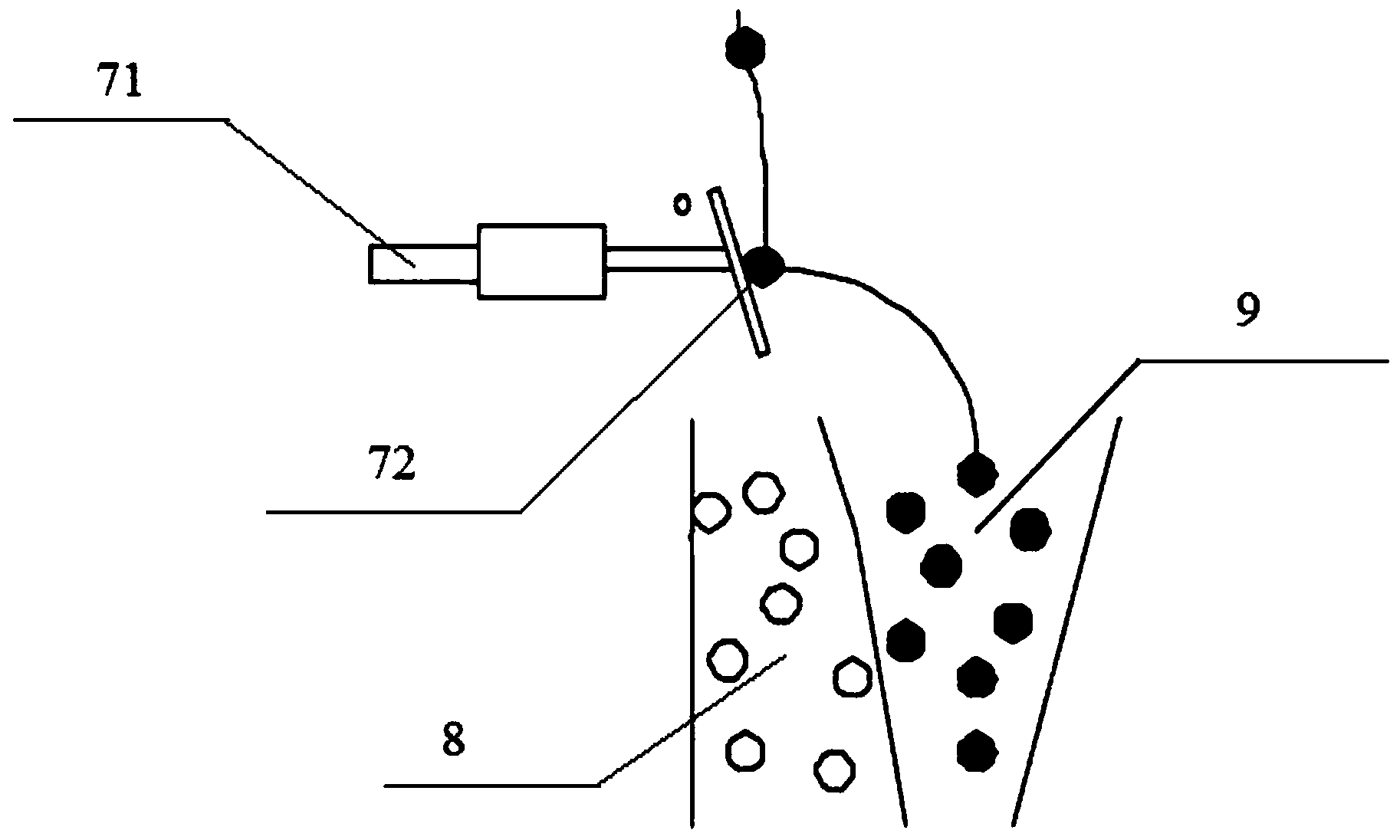

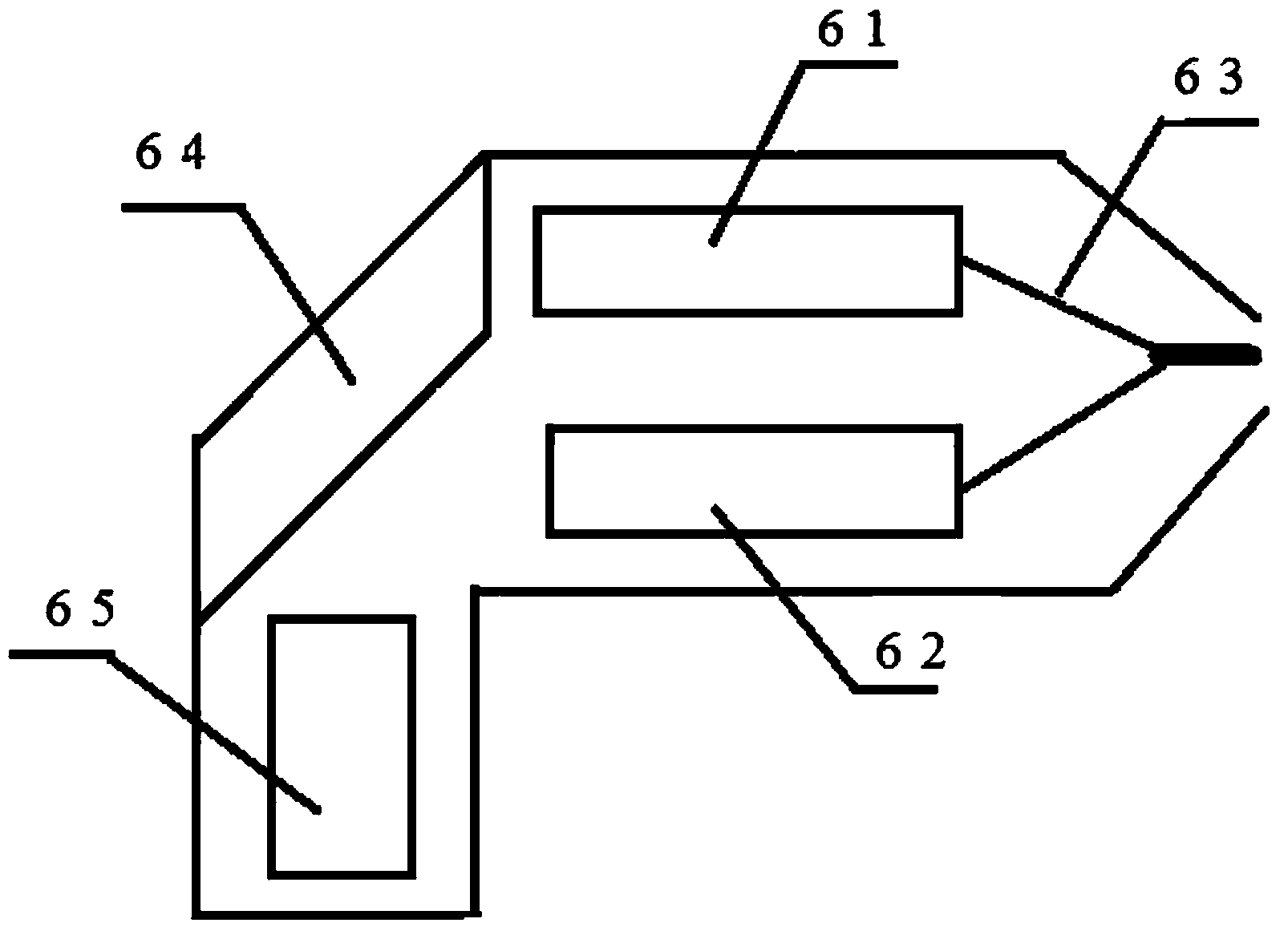

[0026] Laser-induced breakdown spectrum ore intelligent sorting equipment, including ore conveying equipment 1, feeding bin 2, crusher 3, vibrating feeder 4, vibrating launder 5, LIBS sorting system 6, ore separation mechanism 7, concentrate The receiving tank 8 and the tailings receiving tank 9, wherein the LIBS sorting system 6 includes an ultrashort pulse laser 61, a miniature spectrometer 62, an optical fiber guidance system 63, a control and data processing and display module 64, and a battery module 65; wherein the ultrashort pulse laser 61 is a sub-nanosecond laser, and the spectroscopic and detection system 62 is a miniature spectrometer.

[0027] The LIBS sorting system 6 uses a high repetition rate ultrashort pulse laser 61 to generate a certain intensity of plasma on the surface of the material, thereby obtaining a spectral signal with a high signal-to-noise ratio; and the micro-spectrometer 62 achieves a high signal-to-noise ratio for a specific band The analysis a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com