Copper-bearing bimetallic nanometer material with dentritic structure and method for manufacturing copper-bearing bimetallic nanometer material

A technology of bimetallic nano and nanomaterials, applied in the field of copper-containing bimetallic nanomaterials and its preparation, can solve the problems of complexity, high temperature, and step-by-step synthesis process, and achieve less time-consuming reaction, easy-to-obtain raw materials, and easy preparation The effect is simple and convenient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

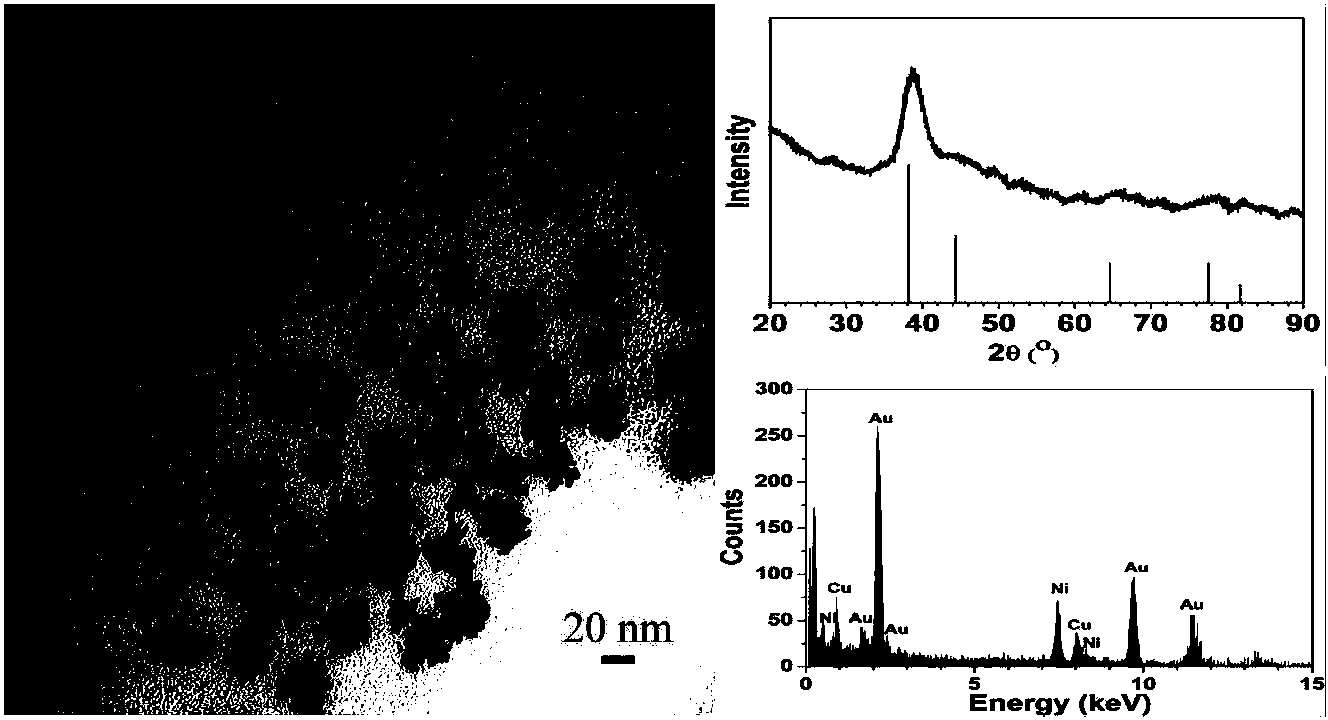

[0036] Weigh 50.6mg P123 into a 20mL sample bottle, add 3.9mL water, stir to dissolve; then add 0.875mL, 0.1mol / L Cu(NO 3 ) 2 solution and 0.26mL, 9.56mg Au / mL HAuCl 4 solution, stirred to form a uniform reaction system solution; added 5mL, 0.1mol / L ascorbic acid for reduction for 1h; transferred the reacted solution to a centrifuge tube, centrifuged, and washed three times with water to obtain a dendritic gold-copper nanostructure. Such as figure 1 As shown, the nanoparticles are aggregated into a dendritic nanostructure. The dendritic nanostructure has a single shape, uniform size, and a size of about 25 nm. It is known as an alloy structure from XRD and EDS analysis.

Embodiment 2

[0038] Weigh 50.6mg P123 into a 20mL sample bottle, add 2.3mL water, stir to dissolve; then add 2.5mL, 0.1mol / L Cu(NO 3 ) 2 solution and 0.26mL, 9.56mg Au / mL HAuCl 4 solution, stirred to form a uniform reaction system solution; added 5mL, 0.1mol / L ascorbic acid for reduction for 1h; transferred the reacted solution to a centrifuge tube, centrifuged, and washed three times with water to obtain a dendritic gold-copper nanostructure. Such as figure 2 As shown, the dendritic nanostructure has a single morphology and an average size of 20 nm.

Embodiment 3

[0040] Weigh 50.6mg P123 into a 20mL sample bottle, add 3.9mL water, stir to dissolve; then add 0.875mL, 0.1mol / L CuCl 2 solution and 0.26mL, 9.56mg Au / mLHAuCl 4 solution, stirred to form a uniform reaction system solution; added 5mL, 0.1mol / L ascorbic acid for reduction for 1h; transferred the reacted solution to a centrifuge tube, centrifuged, and washed three times with water to obtain a dendritic gold-copper nanostructure. Such as image 3 As shown, the dendritic nanostructure has a single morphology and an average size of 35 nm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com