Diffuse-reflection brightness enhancement film and preparation method thereof

A technology of diffuse reflection and brightness enhancement film, applied in optics, instruments, optical components, etc., can solve the problems that the brightness enhancement film cannot be achieved, unfavorable to simplify production, adverse environmental effects, etc., to increase the light mixing effect, avoid light and shadow, increase The effect of the brightening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

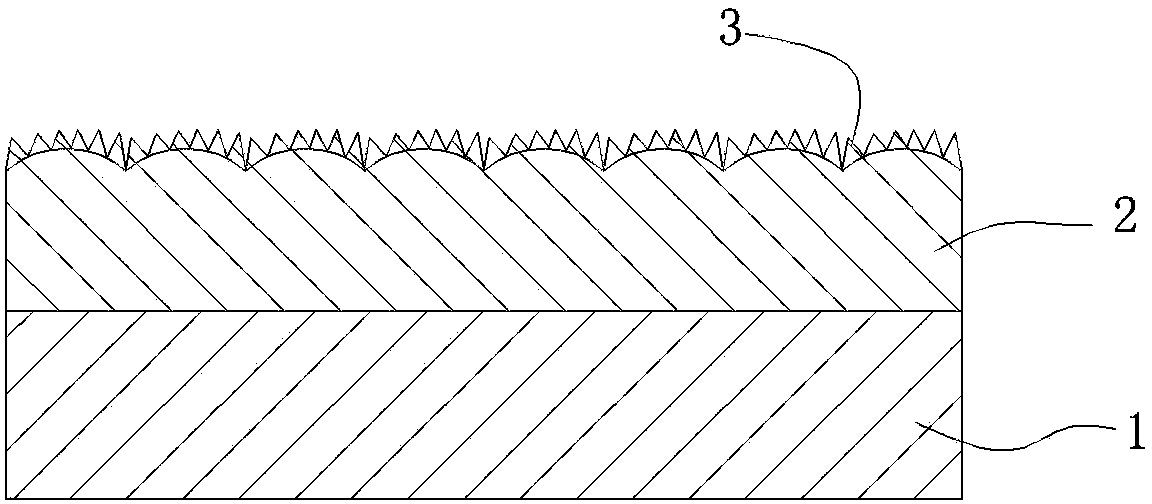

[0021] refer to figure 1 , a kind of diffuse reflective incremental film, comprising a PET base film 1, a layer of PETG layer 2 is also compounded on the PET base film 1, the surface of the PETG layer 2 has several rows of arc-shaped protrusions parallel to each other, Adjacent arc-shaped protrusions are connected to each other, and each row of arc-shaped protrusions has bumps 3 . The protruding point described in this embodiment is a triangular pyramid-shaped protruding point, of course, the protruding point can also be in other shapes, and the triangular pyramid-shaped protruding point has the best light mixing effect.

[0022] The preparation method of the above-mentioned diffuse reflection brightness enhancement film first prepares a molded base film, and the preparation of the molded base film includes the following steps:

[0023] A. Feed the PETG raw material into the extruder, melt and extrude, and set the temperature of the extruder at 150°C;

[0024] B. Feed the PE...

Embodiment 2

[0031] refer to figure 1 , a kind of diffuse reflective incremental film, comprising a PET base film 1, a layer of PETG layer 2 is also compounded on the PET base film 1, the surface of the PETG layer 2 has several rows of arc-shaped protrusions parallel to each other, Adjacent arc-shaped protrusions are connected to each other, and each row of arc-shaped protrusions has bumps 3 . The protruding point described in this embodiment is a triangular pyramid-shaped protruding point, of course, the protruding point can also be in other shapes, and the triangular pyramid-shaped protruding point has the best light mixing effect.

[0032] The preparation method of the above-mentioned diffuse reflection brightness enhancement film first prepares a molded base film, and the preparation of the molded base film includes the following steps:

[0033] A. Feed the PETG raw material into the extruder, melt and extrude, and set the temperature of the extruder at 160°C;

[0034] B. Feed the PE...

Embodiment 3

[0045] refer to figure 1 , a kind of diffuse reflective incremental film, comprising a PET base film 1, a layer of PETG layer 2 is also compounded on the PET base film 1, the surface of the PETG layer 2 has several rows of arc-shaped protrusions parallel to each other, Adjacent arc-shaped protrusions are connected to each other, and each row of arc-shaped protrusions has bumps 3 . The protruding point described in this embodiment is a triangular pyramid-shaped protruding point, of course, the protruding point can also be in other shapes, and the triangular pyramid-shaped protruding point has the best light mixing effect.

[0046] The preparation method of the above-mentioned diffuse reflection brightness enhancement film first prepares a molded base film, and the preparation of the molded base film includes the following steps:

[0047] A. Feed the PETG raw material into the extruder, melt and extrude, and set the temperature of the extruder at 170°C;

[0048] B. Feed the PE...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com