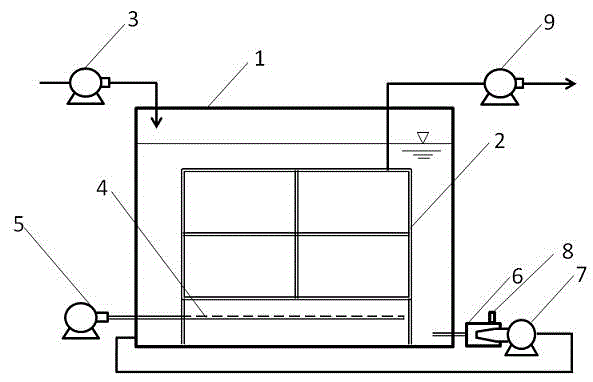

Method and device of composite aeration MBR (membrane bio-reactor)

A technology of compound aeration and aeration holes, applied in the field of compound aeration MBR, can solve the problems of low oxygen transfer rate, poor aeration effect, large aeration energy consumption, etc. The effect of high oxygen efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

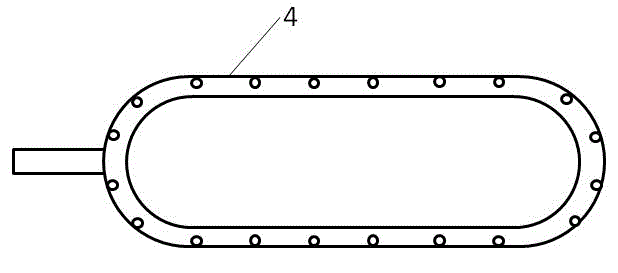

Method used

Image

Examples

Embodiment 1

[0061] A domestic sewage, raw water COD Cr 400mg / L~500mg / L, after treatment with flat plate MBR, COD Cr Reduced to 20 mg / L~50mg / L, reaching the emission standard.

[0062] The membrane flux of the flat MBR membrane is 20~23L / m 2 h, the dissolved oxygen in the flat MBR membrane tank is 2.5~3.5 mg / L, the air-water ratio is 15:1~17:1, the average cleaning cycle of the flat membrane is more than 6 months, and the energy consumption per ton of water is 0.79KW / h .

Embodiment 2

[0064] An industrial wastewater, raw water COD Cr 500mg / L~800mg / L, after treatment with flat MBR, COD Cr <50 mg / L, meet the discharge standard.

[0065] The membrane flux of the flat MBR membrane is 16~20L / m 2 h, the dissolved oxygen in the flat MBR membrane tank is 3.5~4mg / L, the air-water ratio is 18:1~20:1, the average cleaning cycle of the flat membrane is more than 4 months, and the energy consumption per ton of water is 0.82KW / h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com