Method for producing polylactic acid with low lactide monomer content

A monomer content, lactide technology, used in the production of high molecular weight polylactic acid with low lactide monomer content, can solve the problem of hindering operation, reducing the glass transition temperature and melt viscosity of the polymer, formability and heat. Stability deterioration and other problems, to achieve the effect of simple and convenient operation, good formability and thermal stability, and conducive to industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

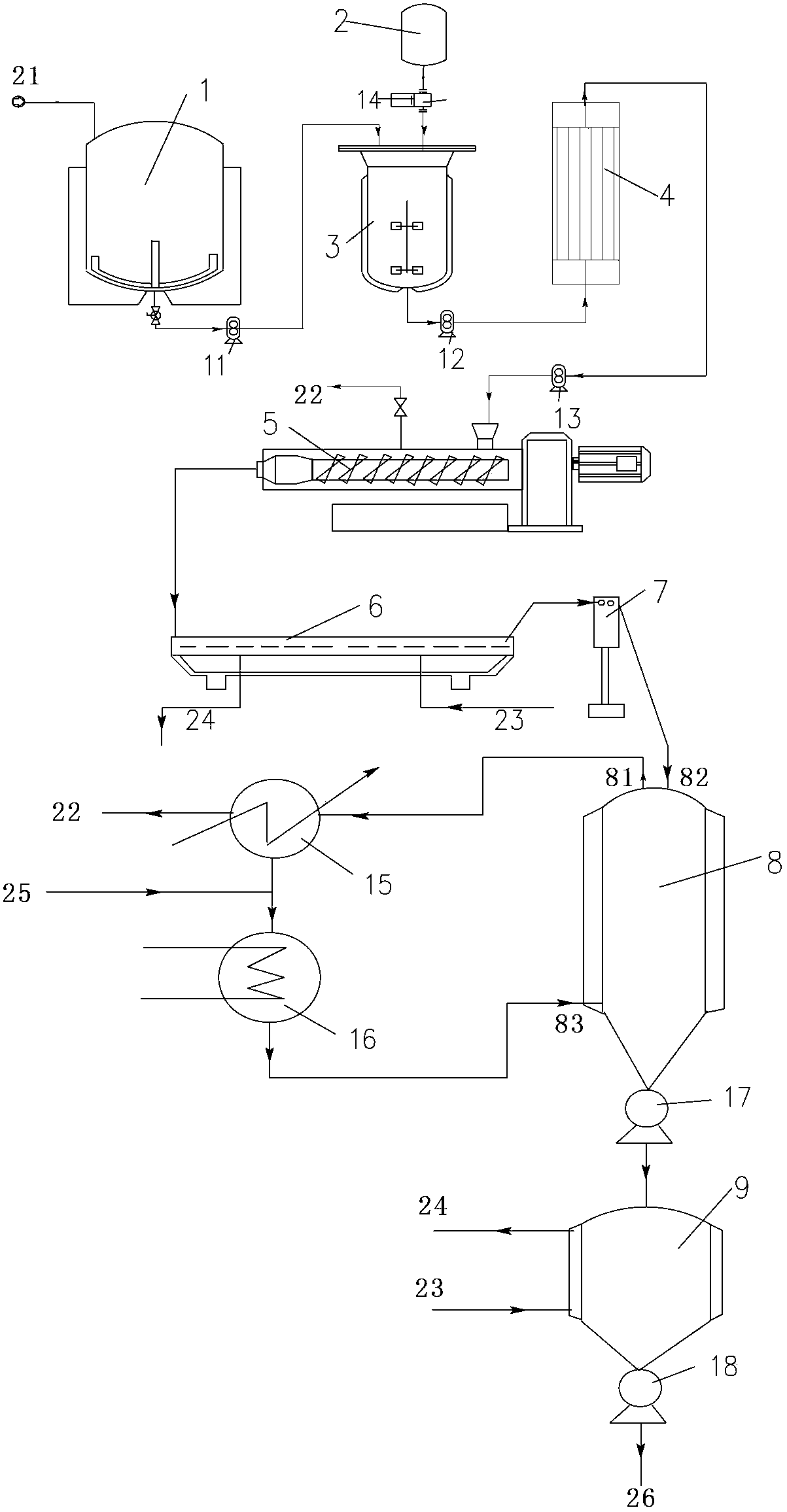

Method used

Image

Examples

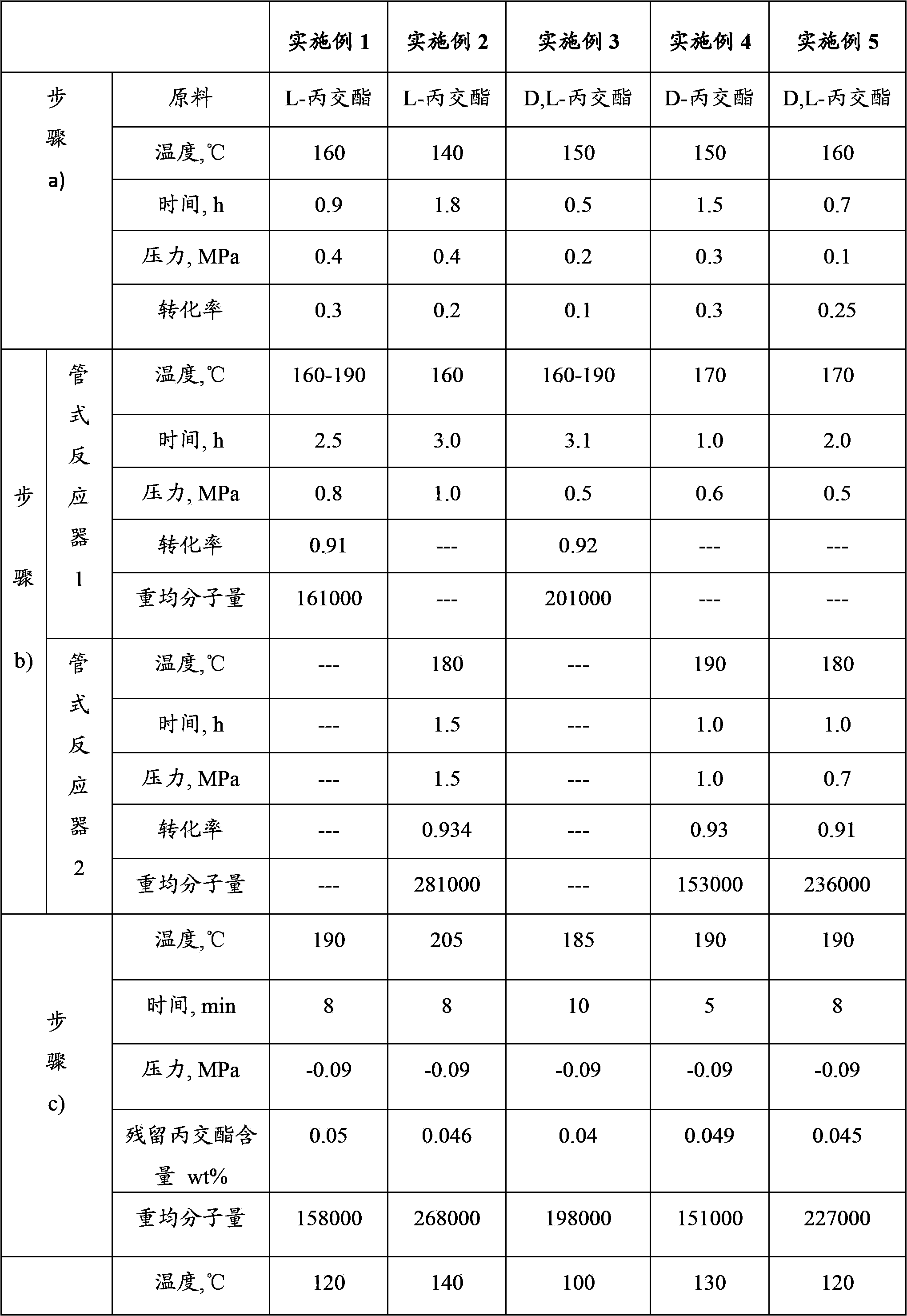

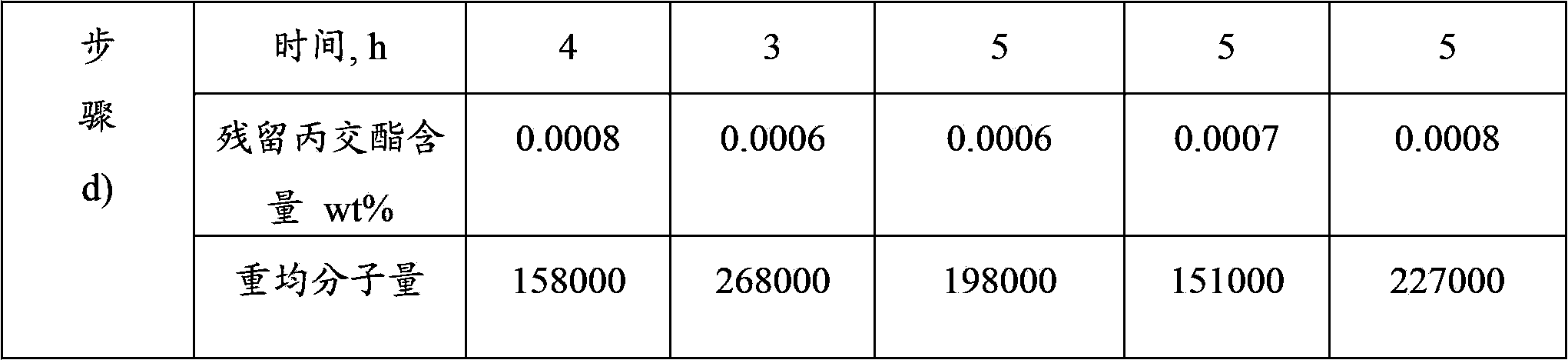

Embodiment 1

[0048] Add 200kg of L-lactide to a 500L melting tank that has been exhausted with nitrogen and has a temperature of 130°C. After the L-lactide is completely melted, 20L of L-lactide is continuously supplied by a melt metering pump at a mass flow rate of 5kg / h. A vertical polymerization kettle, at the same time, the catalyst stannous octoate was continuously supplied to a 20L vertical polymerization kettle at a mass flow rate of 1.5g / h through a catalyst pump, and polymerized at a temperature of 160°C and a pressure of 0.4MPa for 0.9 hours. The conversion rate of lactide reaches 30%. The obtained polymer was sent to a tubular reactor with a melt metering pump, and polymerized at a polymerization temperature of 160-190° C. and a pressure of 0.8 MPa for 2.5 hours. The conversion rate of lactide reached 91%, and the weight average molecular weight of the obtained polylactic acid was 161000.

[0049] The polymer obtained from the tubular reactor was fed into a twin-screw extruder ...

Embodiment 2

[0052] The steps are the same as in Example 1, except that the temperature of the melting tank is 120° C.; the mass flow rate of the catalyst stannous octoate is 2.5 g / h; two tubular reactors connected in series are used; the polylactic acid particles diced after water cooling The weight is 1.0g; the nitrogen gas enters the degassing tower from the lower part of the degassing tower, and the polylactic acid particles and nitrogen gas are heated to 140°C by using the heat transfer oil in the jacket of the degassing tower, and the polylactic acid particles are in countercurrent contact with the nitrogen gas for 3 hours; cool in the cooling kettle The temperature of the obtained polylactic acid particles is about 30°C. The data are shown in Table 1.

Embodiment 3

[0054] The steps are the same as in Example 1, except that the temperature of the melting tank is 140° C.; the raw material D, L-lactide monomer is continuously supplied to the vertical polymerization tank at a mass flow rate of 4.0 kg / h after melting, and the catalyst octanoic acid sub- The mass flow rate of tin is 3.2g / h; the weight of the pelletized polylactic acid particles after water cooling is 2.0g; the temperature of hot nitrogen is 100°C, and the countercurrent contact is 5h. The data are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com