Method and system for recovering waste acid produced from chlorohydric acid pickling of steel

A technology for pickling waste acid and recycling and processing, which is applied in the field of recycling and processing waste acid from hydrochloric acid pickling of steel, and can solve the problems of high energy consumption and high evaporation temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A method for recycling waste acid from hydrochloric acid pickling of steel materials, comprising the following steps:

[0036] Step 101: Pretreating the waste acid from hydrochloric acid pickling to obtain pretreated waste acid.

[0037] Step 102: adding magnesia to the pretreated waste acid for reaction to obtain magnesite cement; wherein, adding 300-500 kg of magnesia per 1000 L of pretreated waste acid.

[0038] Among them, the pretreatment in step 101 is usually conventional treatment such as filtration and decontamination, so as to improve the product recovery rate. In order to increase the reaction rate and efficiency, stirring may also be performed during the reaction in step 102.

[0039] The principle of the above recovery and treatment method is: magnesium oxide reacts with the main components in the waste acid of steel hydrochloric acid pickling - free acid, ferrous chloride and water, and finally produces magnesite cement with industrial value (ie Mg 2 OCL...

Embodiment 2

[0051] A kind of recovery processing method of steel material hydrochloric acid pickling waste acid, such as figure 1 shown, including the following steps:

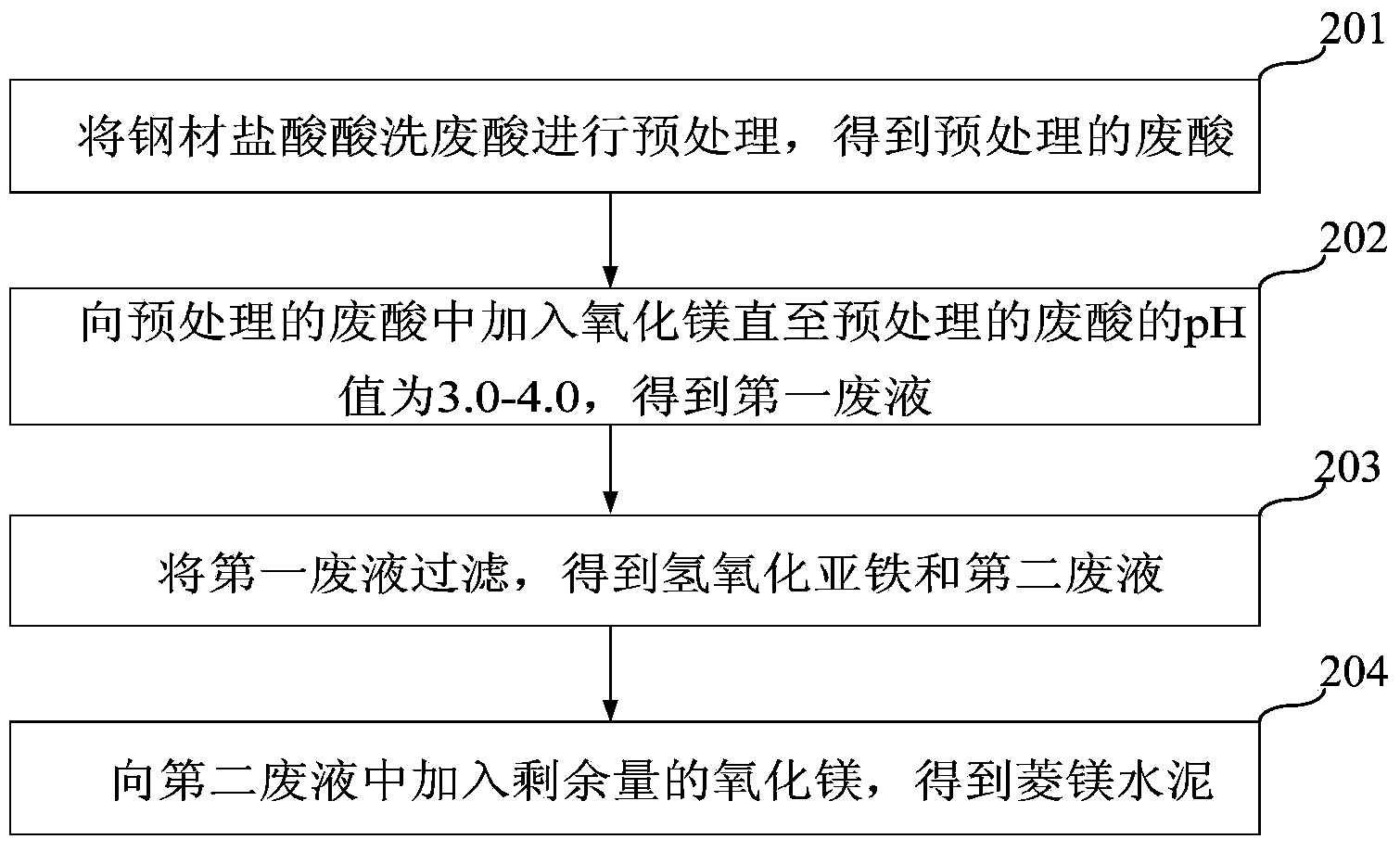

[0052] Step 201: Pretreat the waste acid from hydrochloric acid pickling to obtain pretreated waste acid.

[0053] Step 202: adding magnesium oxide to the pretreated waste acid until the pH value of the pretreated waste acid is 3.0-4.0 to obtain a first waste liquid.

[0054] Step 203: Filter the first waste liquid to obtain ferrous hydroxide and the second waste liquid.

[0055] Step 204: Add the remaining amount of magnesium oxide to the second waste liquid to obtain magnesite cement.

[0056] This embodiment is improved on the basis of Embodiment 1. Magnesium oxide is added in two times to recover more types of products. Wherein, the total amount of magnesium oxide added in step 202 and step 204 is: 300-500 kg of magnesium oxide is added for every 1000 L of pretreated waste acid. In addition, Fe(OH) is obtained in ...

Embodiment 3

[0061] A kind of recovery treatment method of steel product hydrochloric acid pickling waste acid, take processing 1000L waste acid as example, comprises the following steps:

[0062] Step 301: Pretreat the waste acid from hydrochloric acid pickling to obtain pretreated waste acid.

[0063] Step 302: Add 200kg of magnesium oxide to the pretreated waste acid to obtain the first waste liquid.

[0064] Step 303: Filter the first waste liquid to obtain ferrous hydroxide and the second waste liquid.

[0065] Step 304: Add 100kg of magnesium oxide to the second waste liquid to obtain magnesite cement.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com