TDLAS (tunable diode laser absorption spectroscopy)-based intelligent laser ignition device and TDLAS-based intelligent laser ignition method

A laser ignition, intelligent technology, applied in the direction of engine ignition, engine components, machines/engines, etc., can solve the problems of the operation of the internal combustion engine and feedback adjustment, etc., and achieve the effect of expanding the detection and adjustment range and optimizing the application effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the following is merely illustrative and does not limit the scope of the present invention.

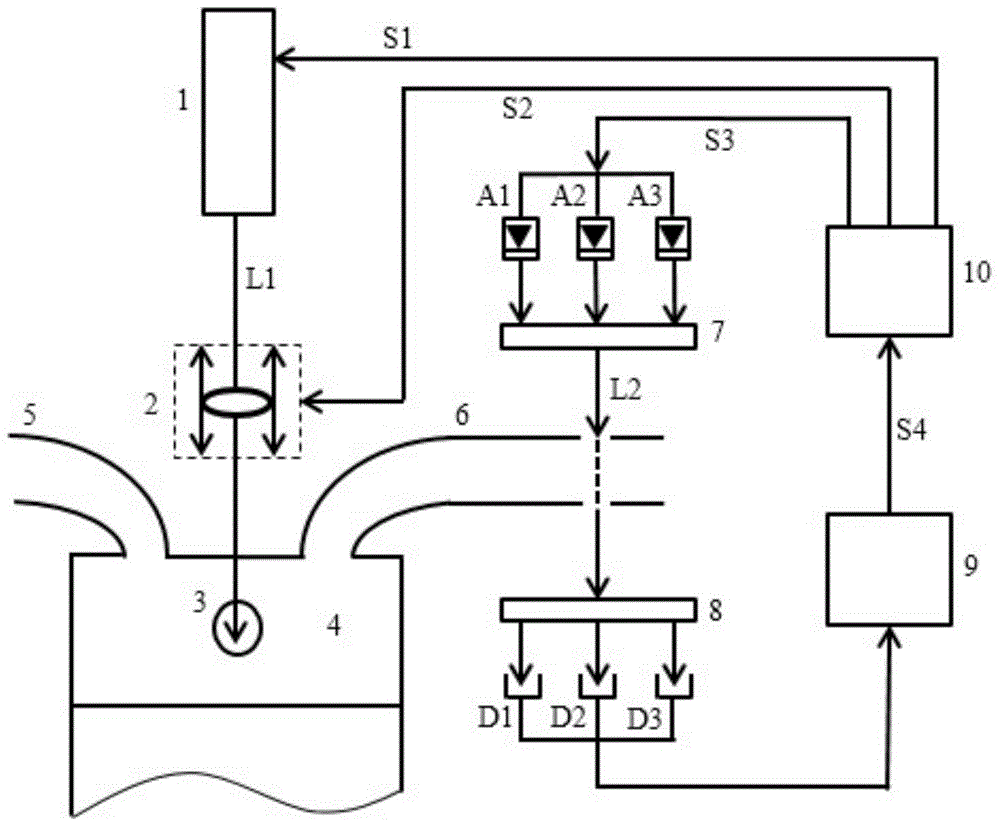

[0038] Such asfigure 1 Shown is a schematic diagram of a TDLAS-based intelligent laser ignition device with exhaust gas as the detection object, including solid-state laser 1, zoom device 2, combustion chamber 4, laser diode A1, laser diode A2, laser diode A3, photodetector D1, photodetector device D2, photodetector D3, signal processor 9 and electronic control unit 10.

[0039] The solid-state laser 1 generates and emits pulsed laser light to the combustion chamber 4 for breakdown ignition; the zoom device 2 is arranged coaxially with the ignition optical path L1 to adjust the focus position of the pulsed laser; the ignition optical path L1 is along the axis of the combustion chamber 4 The center line is injected a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com