Method for measuring optimum extraction condition of metal extractant

An extraction agent and extraction technology, applied in the field of chemical engineering, can solve the problems of high cost and long time consumption, achieve the effect of simple operation and avoid range limitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] 1) Preparation of Microdispersed Droplet Emulsion

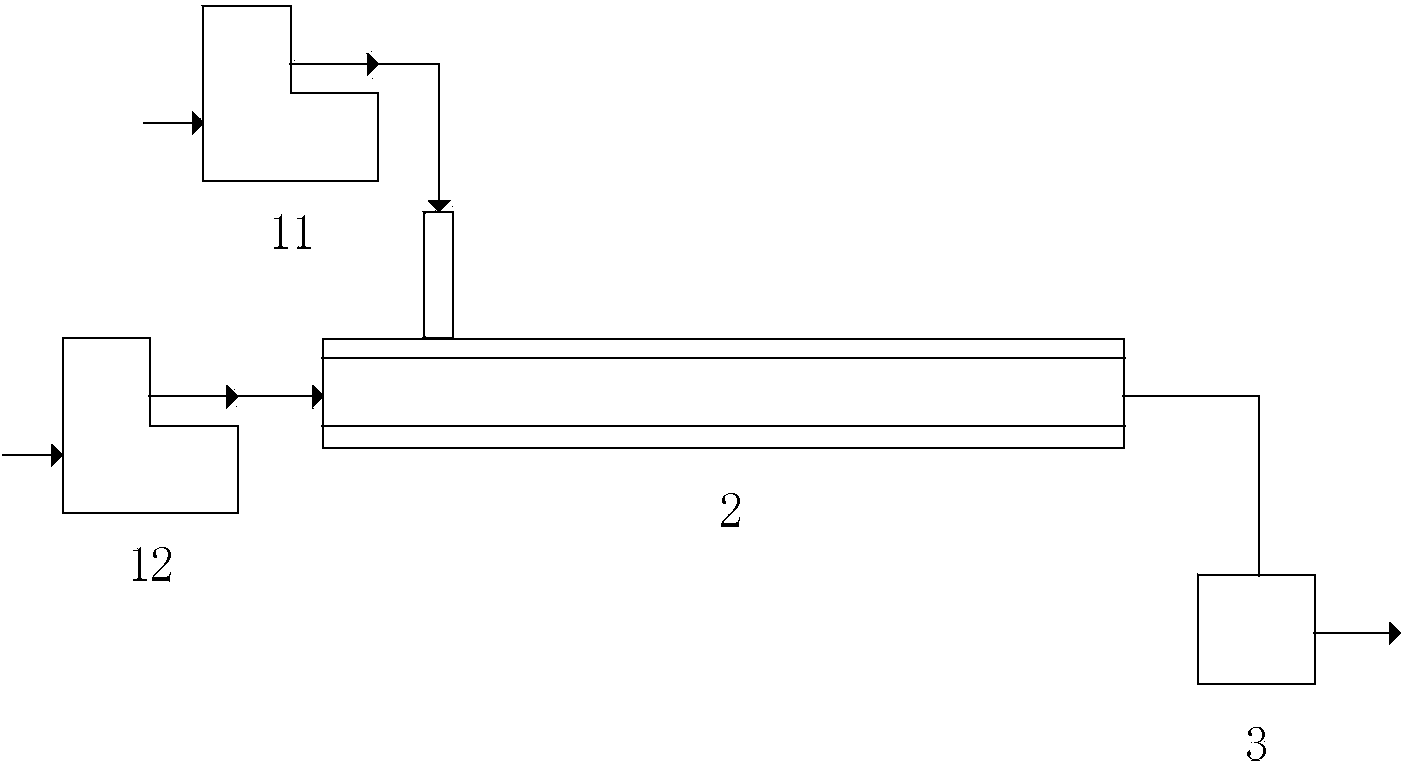

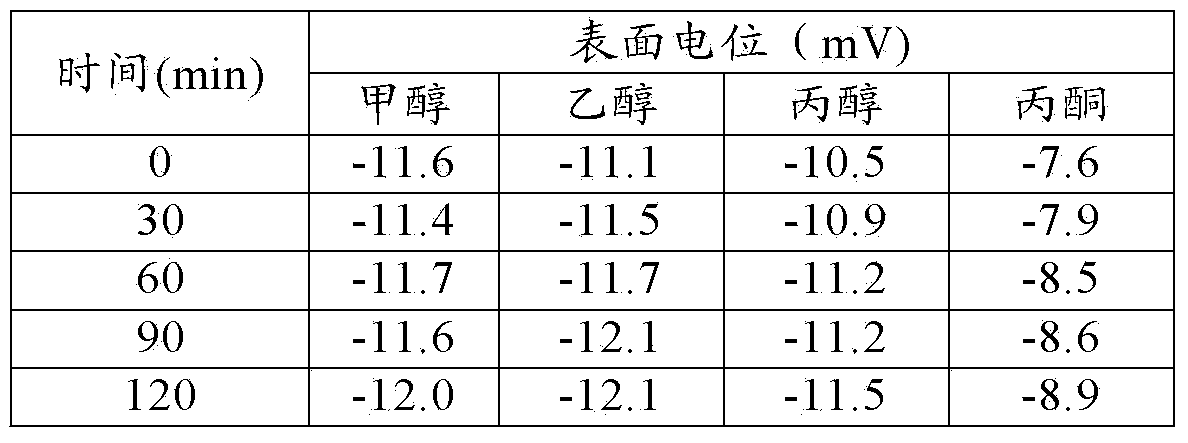

[0040] Dissolve trioctylamine in dodecane diluent to obtain 70×10 -4 mol / L trioctylamine organic phase, the trioctylamine organic phase was mixed with methanol, ethanol, propanol and acetone at a mass ratio of 3:1000, and ultrasonically degassed for 5 minutes to form a homogeneous dispersive solvent. then use figure 1 The membrane dispersing equipment shown in 2 injects the dispersing solvent rapidly into the sodium chloride solution with a concentration of 0.1mmol / L to form a microdispersed droplet emulsion, and the pH of the emulsion is adjusted to 4.0 by NaOH and HCl.

[0041] 2) Determination of surface potential of microdispersed droplet emulsion

[0042] Wash the parts in contact with the emulsion, such as electrodes, sealing rings, and electrodes, three times with deionized water and ethanol, and dry them naturally for later use. Assemble the cleaned parts into a standard electric pool, inject the emulsion to...

Embodiment 2

[0048] 1) Preparation of Microdispersed Droplet Emulsion

[0049] The metal extractant butyl acetate was dissolved in n-octanol diluent to obtain a 1.5 mol / L butyl acetate organic phase. The organic phase of methanol and butyl acetate was mixed according to the mass percentage ratio of 1:100, and then ultrasonically degassed for 5 minutes to obtain a homogeneous dispersive solvent. Potassium chloride was dissolved in deionized water, and ultrasonic degassed for 5 minutes to obtain a potassium chloride solution with an ionic strength of 0.000001 mol / L.

[0050] Then use membrane dispersing equipment to quickly inject the dispersing solvent into the potassium chloride solution. Under the hydrophilic and hydrophobic effects of the solvent, the hydrophilic organic solvent will quickly dissolve in the inorganic salt solution, while the hydrophobic metal extractant will dissolve in the inorganic salt solution. Rapid precipitation in saline solution to form microdispersed droplet em...

Embodiment 3

[0058] 1) Preparation of Microdispersed Droplet Emulsion

[0059]The metal extractant trialkylphosphine oxide was dissolved in n-hexane diluent to obtain a 0.3 mol / L trialkylphosphine oxide organic phase. The acetonitrile and the trialkylphosphine oxide organic phase were mixed according to the ratio of 1:2000 by mass percentage to obtain a mixed liquid, and then ultrasonically degassed for 5 minutes to obtain a homogeneous dispersive solvent. Potassium chloride was dissolved in deionized water and ultrasonically degassed for 5 minutes to obtain a magnesium chloride solution with an ionic strength of 0.1 mol / L.

[0060] Then use membrane dispersing equipment to quickly inject the dispersing solvent into the potassium chloride solution. Under the hydrophilic and hydrophobic effects of the solvent, the hydrophilic organic solvent will quickly dissolve in the inorganic salt solution, while the hydrophobic metal extractant will dissolve in the inorganic salt solution. Rapid preci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| ionic strength | aaaaa | aaaaa |

| ionic strength | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com