Oxygen content detecting method for boiler fuel gas of coal-fired power station

A technology for flue gas oxygen content and boiler flue gas, which is applied in the direction of electrical digital data processing, special data processing applications, instruments, etc., can solve the problems of model accuracy decline and model update without consideration, and achieve low cost and no increase Hardware equipment, high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] In a preferred embodiment, a soft measuring method for oxygen content in flue gas of a coal-fired power plant boiler, the specific steps of the design method are as follows:

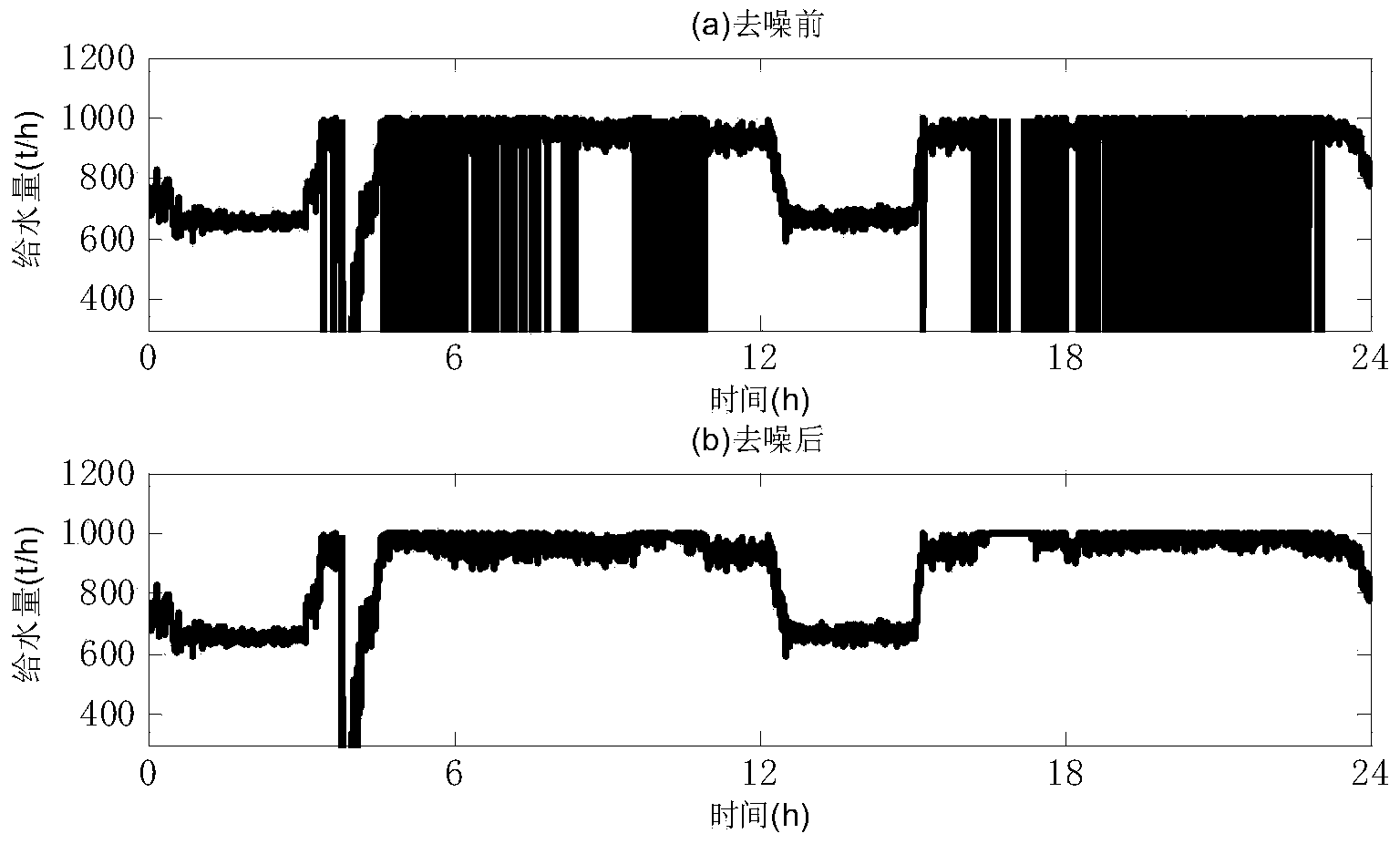

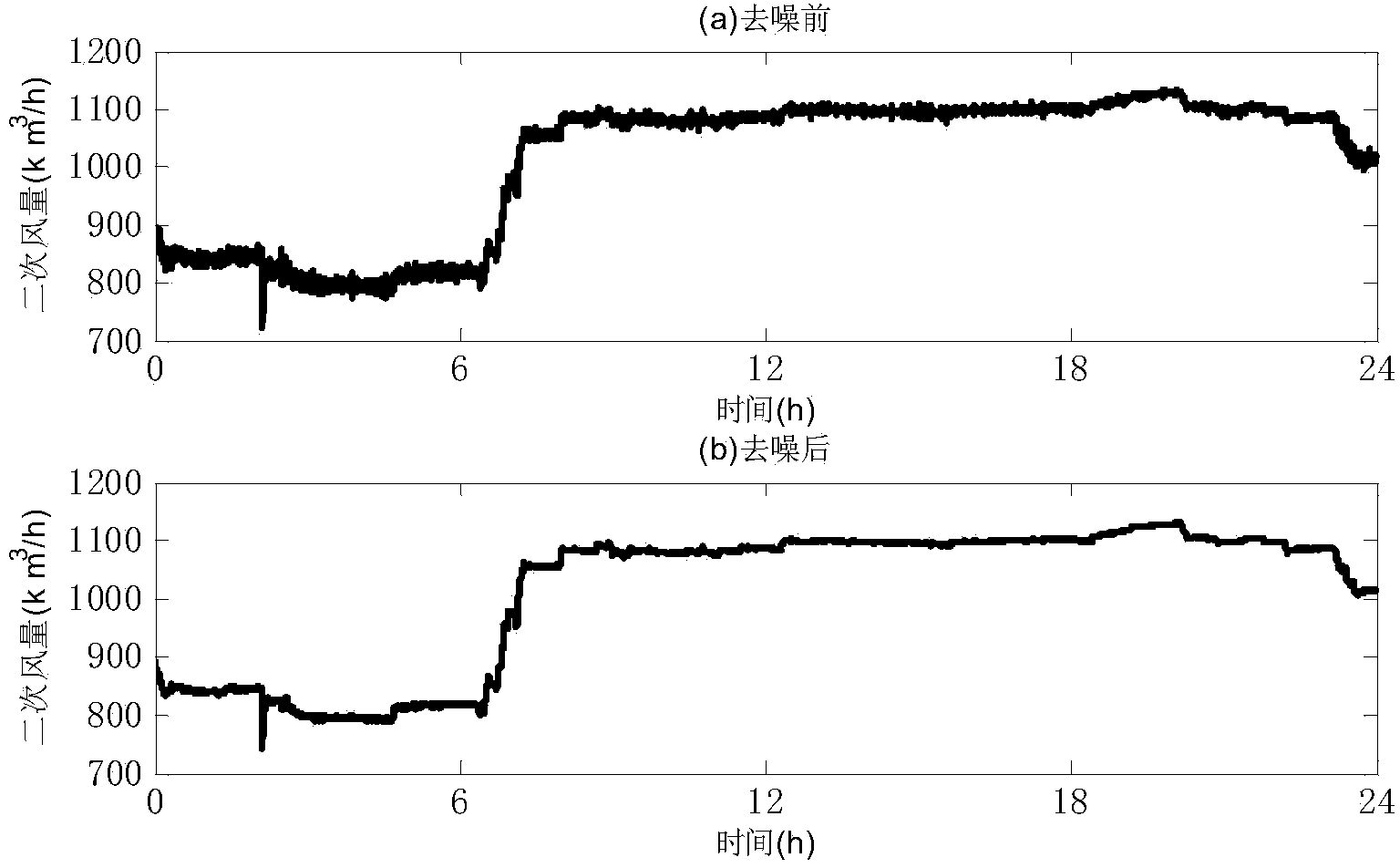

[0047] Step 1. Raw data acquisition

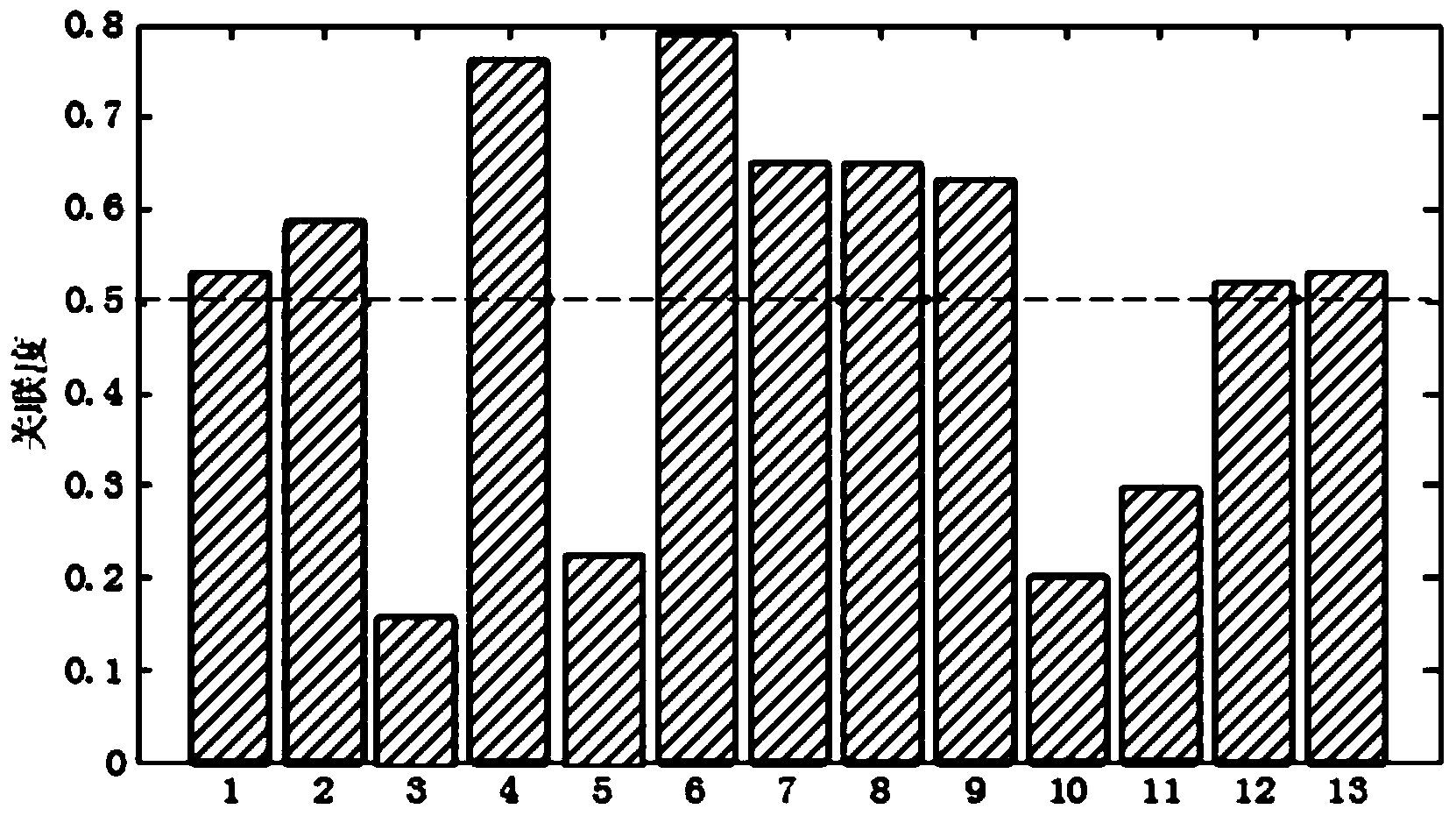

[0048] Through the distributed control system of the power station, the operating variables related to the oxygen content of the flue gas are obtained. In order to soft measure the oxygen content in the flue gas of coal-fired boilers, it is first necessary to find indirect variables closely related to it as the input variables of the soft sensing model. The main reason for the generation of oxygen in the flue gas is that the amount of air input to the boiler is greater than the amount of air required for pulverized coal combustion, and part of the oxygen in the air does not participate in the combustion chemical reaction. Therefore, the oxygen signal in the flue gas is closely related to various variables in the combustion system. In this paper, the followin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com