Composite powder and method for producing same

A technology of composite powder and manufacturing method, which is applied in the direction of chemical instruments and methods, pharmaceutical formulas, and cosmetic preparations, etc. It can solve the problems of skin shielding, deterioration of ultraviolet shielding efficiency, and destruction of chemical bonds of other components, and achieve surface activity. Excellent effect of inhibition and storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

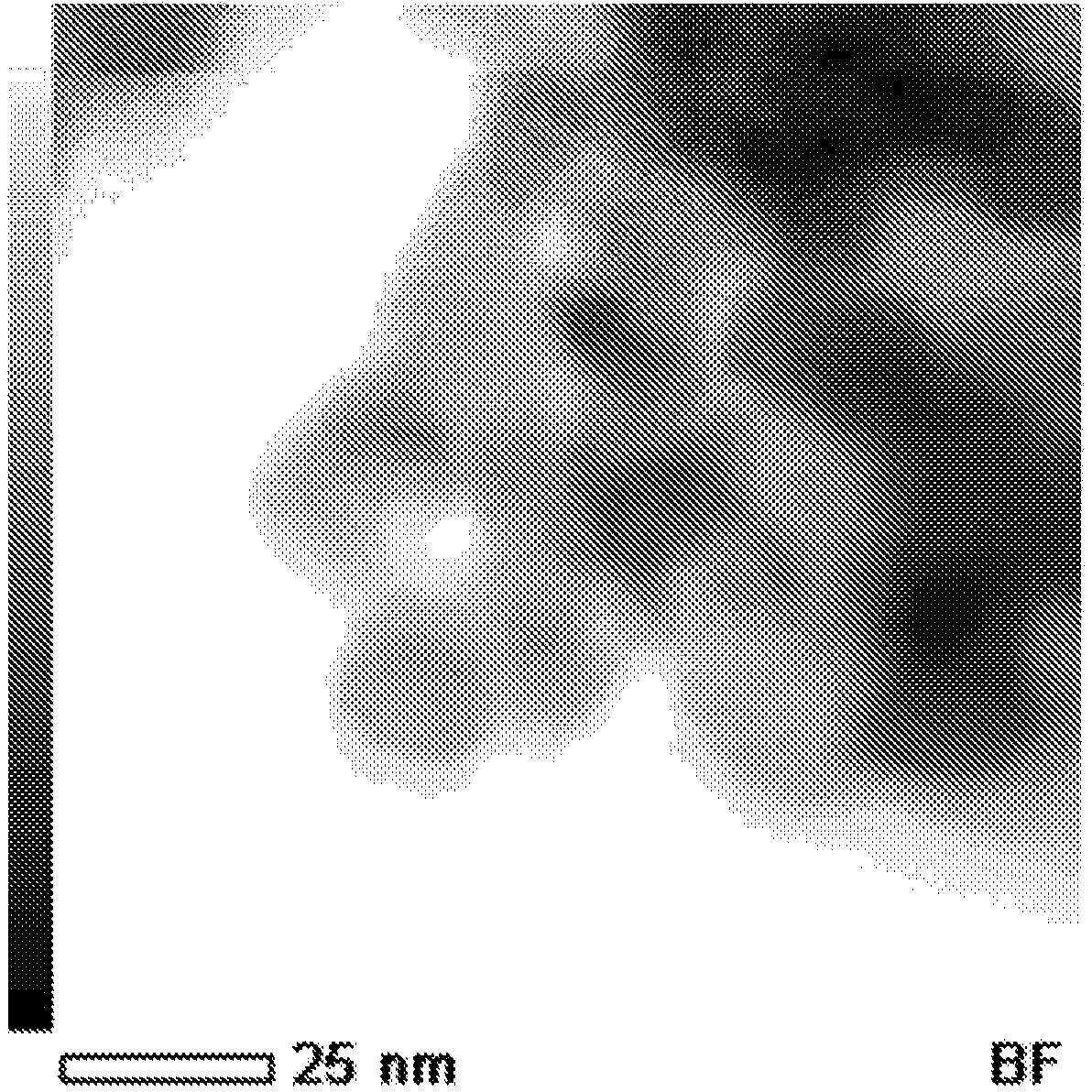

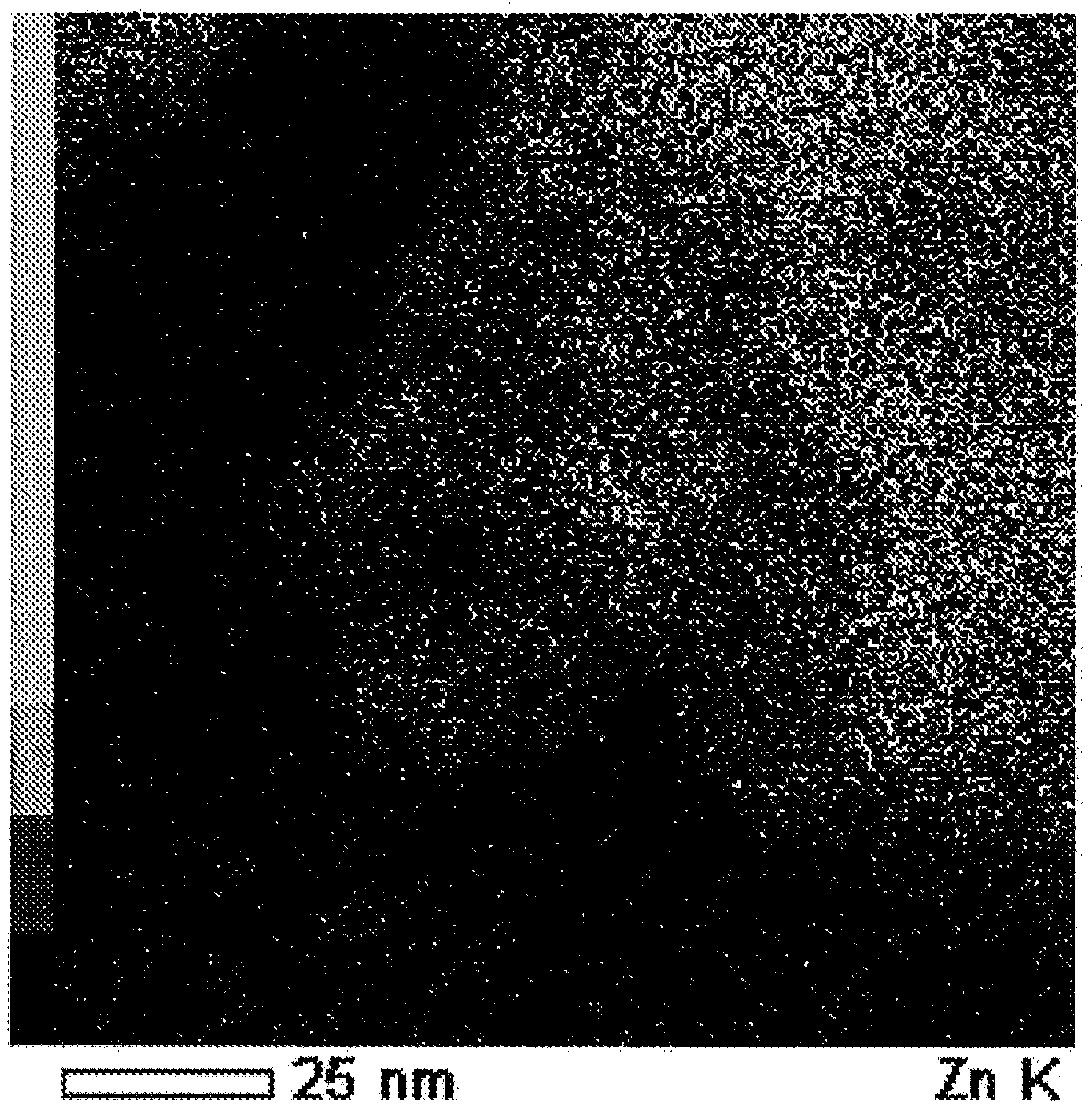

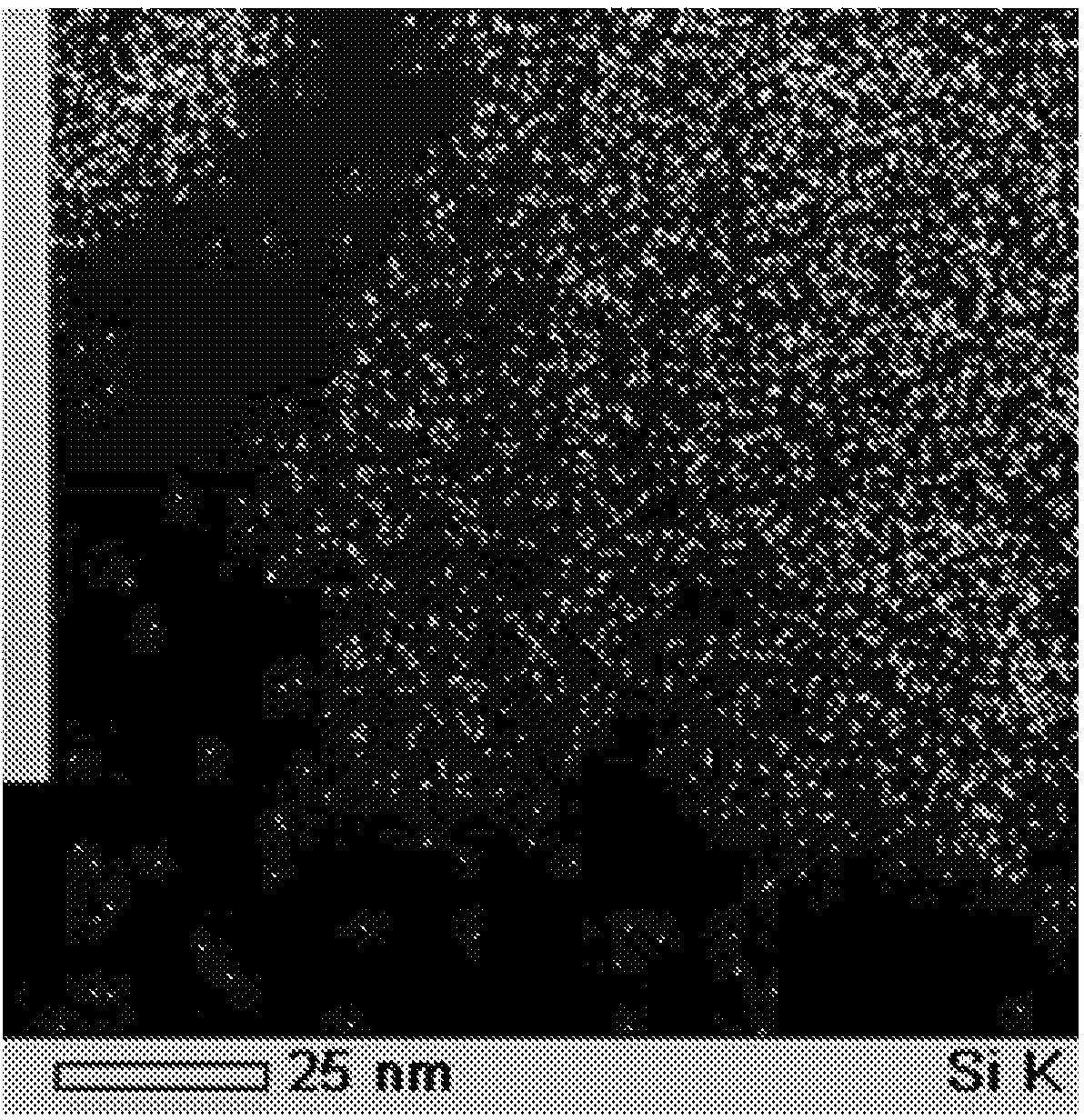

Image

Examples

Embodiment 1

[0092] Add 20g of polyether-modified silicone (KF-6011: manufactured by Shin-Etsu Chemical Industry: HLB 14.5) to 500mL of pure water, and further add zinc oxide (FINEX- 50S-LP2) 100g, mix and disperse. Add 27.5ml (as SiO 2 The amount is 11.1g, which is 10% by weight of the whole powder body after treatment) of sodium silicate aqueous solution (SiO 2 : 403.9g / L, Na 2 O: 130.7g / L), stirring for more than 20 minutes. Then, liquid temperature was made into 70 degreeC. A certain amount of dilute sulfuric acid is added dropwise for neutralization. When performing this neutralization, the amount of sulfuric acid added dropwise was adjusted so that the state of pH 8.5 or higher was maintained for 90 minutes or longer, and neutralization was performed until pH 6.5±0.5. After completion of neutralization, aging was carried out at a liquid temperature of 70° C. for 1 hour. Thereafter, filtration and water washing were performed. The obtained water-washed cake was dried to obtain ...

Embodiment 2

[0094] Zinc oxide treated with 4% hydrogenated dimethicone (FINEX-50S-LP2) was changed to zinc oxide treated with 7% hydrogenated dimethicone (FINEX-50-LPT: Sakai Chemical Industry Co., Ltd.), except that, a composite powder 2 was obtained in the same manner as in Example 1.

Embodiment 3

[0096] Add 20g of polyether-modified silicone (KF-6011: manufactured by Shin-Etsu Chemical Industry: HLB 14.5) to 500mL of pure water, and further add zinc oxide (FINEX- 50-LPT) 100g, stirred to disperse. After this dispersion liquid is heated up to 70 ℃, prepare sodium silicate aqueous solution 27.5ml (the SiO in the solution 2 The amount is 11.1 g, which is 10% by weight of the whole powder after treatment) and dilute sulfuric acid, which were dropped into the above-mentioned dispersion liquid respectively. When performing this dropwise addition, the dropwise amount was adjusted so that the pH was kept stable in the range of 5.5 to 7.5, and it was adjusted so that the dropwise end time would be 2 hours later. After completion of the dropwise addition, aging was performed for 1 hour while maintaining the liquid temperature at 70°C. Thereafter, filtration and water washing were performed, and the obtained water-washed cake was dried to obtain composite powder 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com