High water content seasoning prawn preparation method

A technology of seasoning prawns with high water content, which is applied in food preparation, food preservation, food science, etc. It can solve the problems of easy spoilage, deep processing technology has not made great strides, and preservation methods are not advanced enough to achieve long shelf life and rich nutrition , easy to carry effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

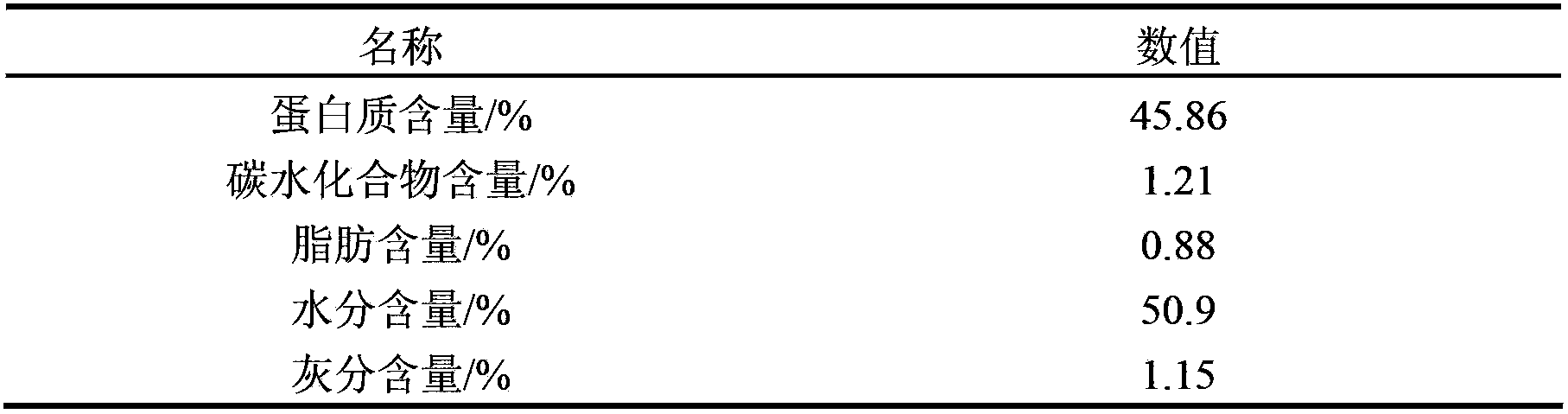

Embodiment 1

[0023] 1) Raw material pretreatment: select frozen prawns that have not been refrigerated for more than 4 months and have no browning on the head, and use drench water or flow water to freeze, remove mud and sand, then remove heads, tails, shells, and put The intestinal glands on the back are removed and washed for later use;

[0024] 2) Pre-cooking: Weigh a certain amount of pretreated prawns, weigh a certain amount of water according to the mass ratio of water and shrimp as 2:1, boil the water first, then pour the shrimp into the prawns and cook for 2 minutes, then put the Remove the good shrimp from the pot and drain the water;

[0025] 3) Sterilization: After cooling the cooked shrimp for a certain period of time, soak the shrimp and strongly acidic electrolyzed water in the strongly acidic electrolyzed water with pH=3 in a mass ratio of 1:5 for 25 minutes, and the soaking temperature is 4°C;

[0026] 4) Prepare seasoning liquid: add a little onion and ginger to 100mL, bo...

Embodiment 2

[0031] 1) Raw material pretreatment: select frozen prawns that have not been refrigerated for more than 4 months and have no browning on the head, and use drench water or flow water to freeze, remove mud and sand, then remove heads, tails, shells, and put The intestinal glands on the back are removed and washed for later use;

[0032] 2) Pre-cooking: Weigh a certain amount of pretreated prawns, weigh a certain amount of water according to the mass ratio of water and shrimp to be 2:1, boil the water first, then pour the shrimp into the prawns and cook for 3 minutes. Remove the good shrimp from the pot and drain the water;

[0033] 3) Sterilization: After cooling the cooked shrimp for a certain period of time, soak the shrimp and strongly acidic electrolyzed water in the strongly acidic electrolyzed water with pH=3 in a mass ratio of 1:5 for 25 minutes, and the soaking temperature is 4°C;

[0034] 4) Prepare seasoning liquid: add a little onion and ginger to 100mL, boil and boi...

Embodiment 3

[0039] 1) Raw material pretreatment: select frozen prawns that have not been refrigerated for more than 4 months and have no browning on the head, and use drench water or flow water to freeze, remove mud and sand, then remove heads, tails, shells, and put The intestinal glands on the back are removed and washed for later use;

[0040] 2) Pre-cooking: Weigh a certain amount of pretreated prawns, weigh a certain amount of water according to the mass ratio of water and shrimp to be 2:1, boil the water first, then pour the shrimp into the prawns and cook for 3 minutes. Remove the good shrimp from the pot and drain the water;

[0041] 3) Sterilization: After cooling the cooked shrimp for a certain period of time, soak the shrimp and strongly acidic electrolyzed water in the strongly acidic electrolyzed water with pH=3 in a mass ratio of 1:5 for 25 minutes, and the soaking temperature is 4°C;

[0042] 4) Prepare seasoning liquid: add a little onion and ginger to 100mL, boil and boi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com