Automatic spraying device capable of walking and spraying method thereof

A technology of automatic spraying and traveling wheels, applied in spraying devices, buildings, building structures, etc., can solve the problems of controlled work place, uneven spraying, loss of competitiveness, etc., and reduce uncertain factors and construction time. The effect of saving and reducing personal injury

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

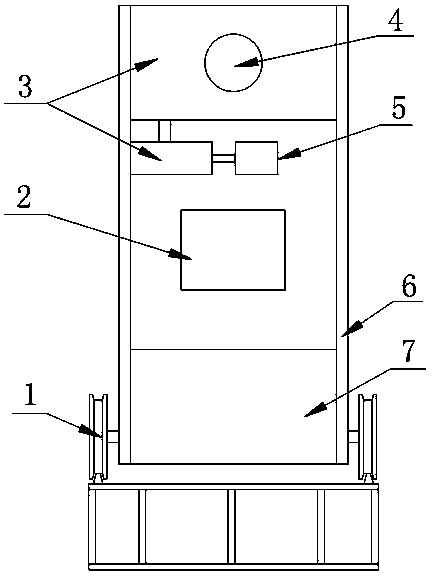

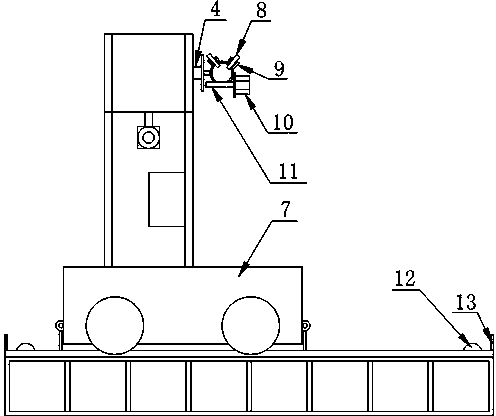

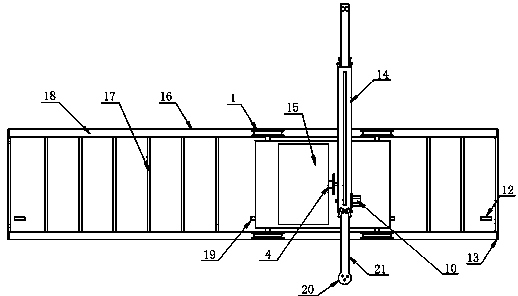

[0031] Such as figure 1 , figure 2 , image 3 As shown, the automatic spraying device capable of walking includes a car body 7 and a slide rail 16 arranged below the car body 7, the car body 7 can move along the slide rail 16, and the car body 7 is provided with a support frame 6, and The inside of the support frame 6 is provided with a control integration box 2 and a bipolar transmission gearbox 3 that can move in the vertical direction inside the support frame 6. The bipolar transmission gearbox 3 is connected with an internal hollow support tube 14, and the support tube 14 Set outside the support frame 6, the two ends of the support tube 14 are all provided with a support wheel set, the inside of the support tube 14 is provided with a spraying rod 21, and the two ends of the spray rod 21 extend out of the two ends of the support tube 14 respectively, One end of the pipe 14 is provided with a rotating tooth 11 , and the spraying rod 21 meshes with the rotating tooth 11 , ...

Embodiment 2

[0048] The structure of embodiment 2 is basically the same as that of embodiment 1, and the method of spraying in the horizontal direction is adopted: the telescopic motor is turned on to drive the rotation of the rotating gear, and through the meshing of the rotating gear and the tooth mark of the spraying rod, the horizontal movement of the spraying rod is driven to change the rotation of the rotating gear. The direction of rotation, the horizontal movement direction of the spray rod also changes, and the spray gun can spray in the horizontal direction.

[0049] The rotating gear 11 is a device driven by a telescopic motor. The rotating gear 11 is always in mesh with the spraying rod 21. When the rotating gear 11 is driven, the tooth marks at the bottom of the spraying rod 21 engage with the rotating gear 11 in the horizontal direction, slowly driving the spraying The rod 21 is sprayed in the horizontal direction, the length of the spray rod is 4 meters, and the spraying dist...

Embodiment 3

[0053] Fan-surface spraying: Run step (a) and step (b) at the same time to achieve fan-surface spraying effect. In the case of simultaneous movement of the bipolar transmission gearbox and the rotating gear, the trajectory of the spraying rod is a parabola, and the trajectory of the entire spray gun is a fan-shaped surface. The movement of the walking trolley on the slide rail drives the spraying device to perform spraying at different positions. spraying.

[0054] When the bipolar gear box and the rotating gear move at the same time, the spraying rod moves both vertically and horizontally, and the effect of spraying in the spray gun is parabolic. Using its own weight and the continuous impact force of the spray gun, the whole All the walls can be sprayed in place, which reduces the trouble of multiple spraying back and forth and improves the construction efficiency.

[0055] The walking trolley walks on the slide rail and moves along the track of the rail. The wheel surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com