Heat-resisting flame-retardant isocyanurate-ring-containing polyether polyol with controllable hard segment/soft segment ratio and preparation method thereof

A technology of isocyanurate and oxypropyl isocyanurate, which is applied in the field of heat-resistant flame-retardant polyether polyol and its preparation, can solve the problem that the molecular weight of polyether polyol is difficult to control, and avoid Process, easy to achieve, low equipment requirements

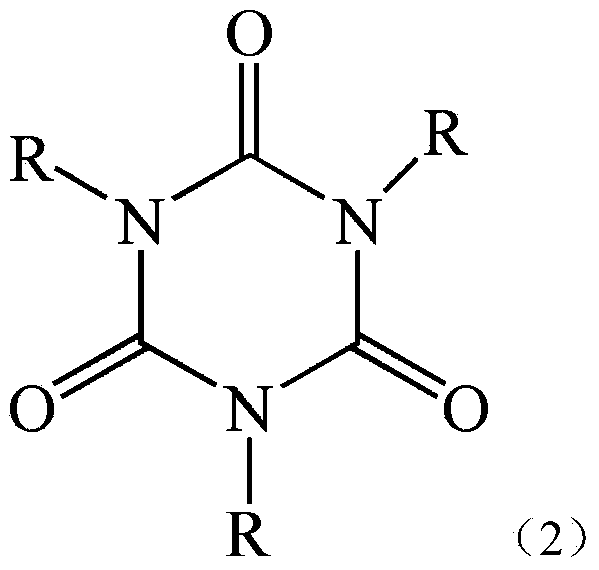

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Diethylene glycol-TGIC polyether polyol

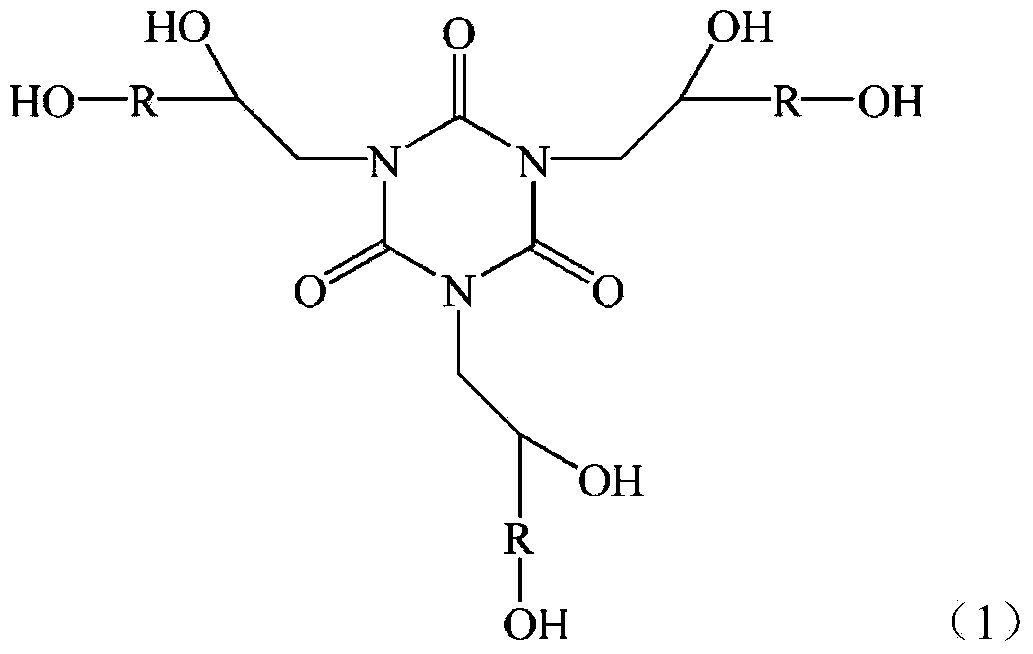

[0032] 1) Product Description

[0033] Molecular weight: 615.6g / mol

[0034] Molecular Structure:

[0035]

[0036] Appearance: light yellow transparent liquid

[0037] Hydroxyl value: 540mgKOH / g

[0038] Moisture: ≤0.5wt%

[0039] Uses: rigid polyurethane foam

[0040] 2) Synthesis technology

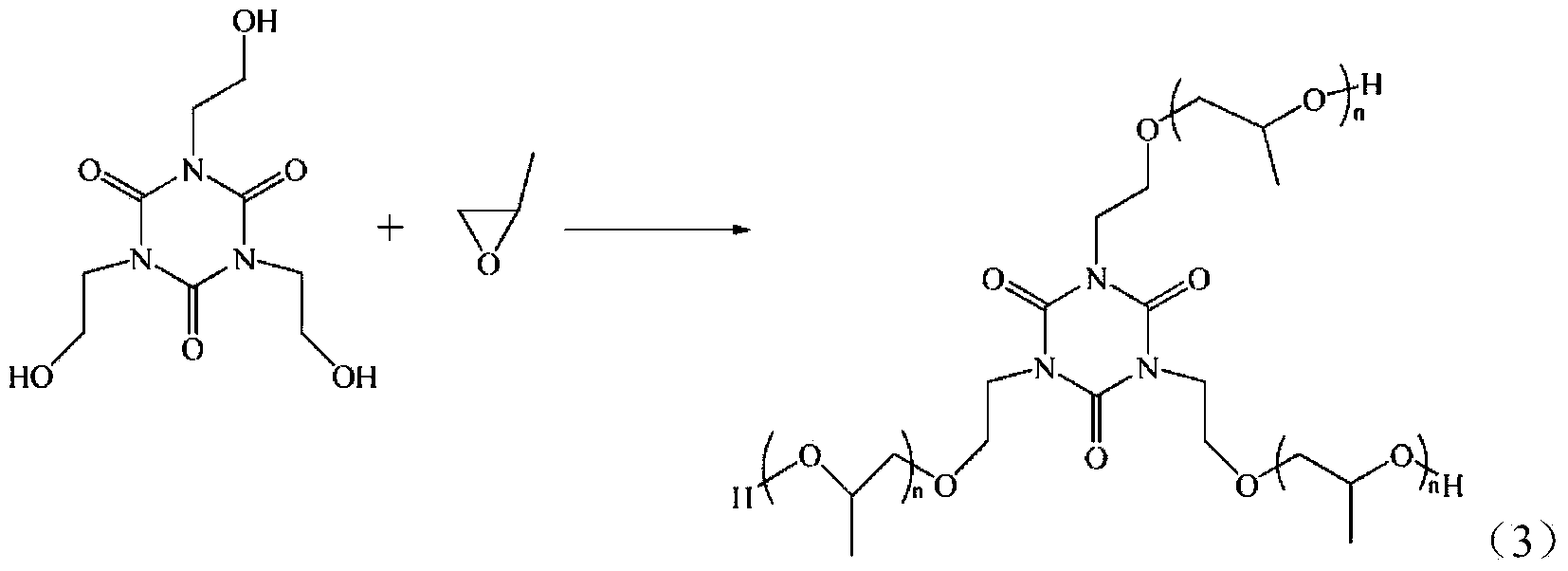

[0041] Chemical reaction formula:

[0042]

[0043] Synthetic steps:

[0044] a. Add 31.8kg of diethylene glycol into the reaction kettle, raise the temperature to 90°C, and start the mechanical stirring;

[0045] b. Add 29.7kg triglycidyl isocyanurate into the above reaction kettle in 5 times within 45min;

[0046] c. After step b is completed, the temperature is raised to 140° C., and the epoxy group and the hydroxyl group are subjected to a ring-opening reaction, and the reaction is performed for 2 hours, and the stirring is stopped;

[0047] d. Naturally cool to room temperature to obtain 61kg product diethylene glyco...

Embodiment 2

[0049] Triethylene glycol-TGIC polyether polyol

[0050] 1) Product Description

[0051] Molecular weight: 747g / mol

[0052] Molecular Structure:

[0053]

[0054] Appearance: light yellow transparent liquid

[0055] Hydroxyl value: 450mgKOH / g

[0056] Moisture: ≤0.5wt%

[0057] Uses: rigid polyurethane foam

[0058] 2) Synthesis technology

[0059] Chemical reaction formula:

[0060]

[0061] Synthetic steps:

[0062] a. Add 45kg of triethylene glycol into the reaction kettle, raise the temperature to 100°C, and start the mechanical stirring;

[0063] b. Add 29.7kg triglycidyl isocyanurate into the above reaction kettle in 5 times within 1 hour;

[0064] c. After step b is completed, the temperature is raised to 150° C., and the epoxy group and the hydroxyl group are subjected to a ring-opening reaction, and the reaction is 3 hours, and the stirring is stopped;

[0065] d. Cool naturally to room temperature to obtain 74kg of product triethylene glycol-TGIC pol...

Embodiment 3

[0067] Polyethylene glycol 200-TGIC polyether polyol

[0068] 1) Product Description

[0069] Molecular weight: 897g / mol

[0070] Molecular Structure:

[0071]

[0072] Appearance: light yellow transparent liquid

[0073] Hydroxyl value: 375mgKOH / g

[0074] Moisture: ≤0.5wt%

[0075] Uses: rigid polyurethane foam

[0076] 2) Synthesis technology

[0077] Chemical reaction formula:

[0078]

[0079] Synthetic steps:

[0080] a. Add 60kg polyethylene glycol 200 into the reaction kettle, raise the temperature to 110°C, and start the mechanical stirring;

[0081] b. Add 29.7kg triglycidyl isocyanurate into the above reaction kettle in 5 times within 75min;

[0082]c. After step b is completed, the temperature is raised to 160° C., and the epoxy group and the hydroxyl group are subjected to a ring-opening reaction, and the reaction is 2.5 hours, and the stirring is stopped;

[0083] d. Naturally cool to room temperature to obtain 89kg of product polyethylene glycol ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hydroxyl value | aaaaa | aaaaa |

| Hydroxyl value | aaaaa | aaaaa |

| Hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com