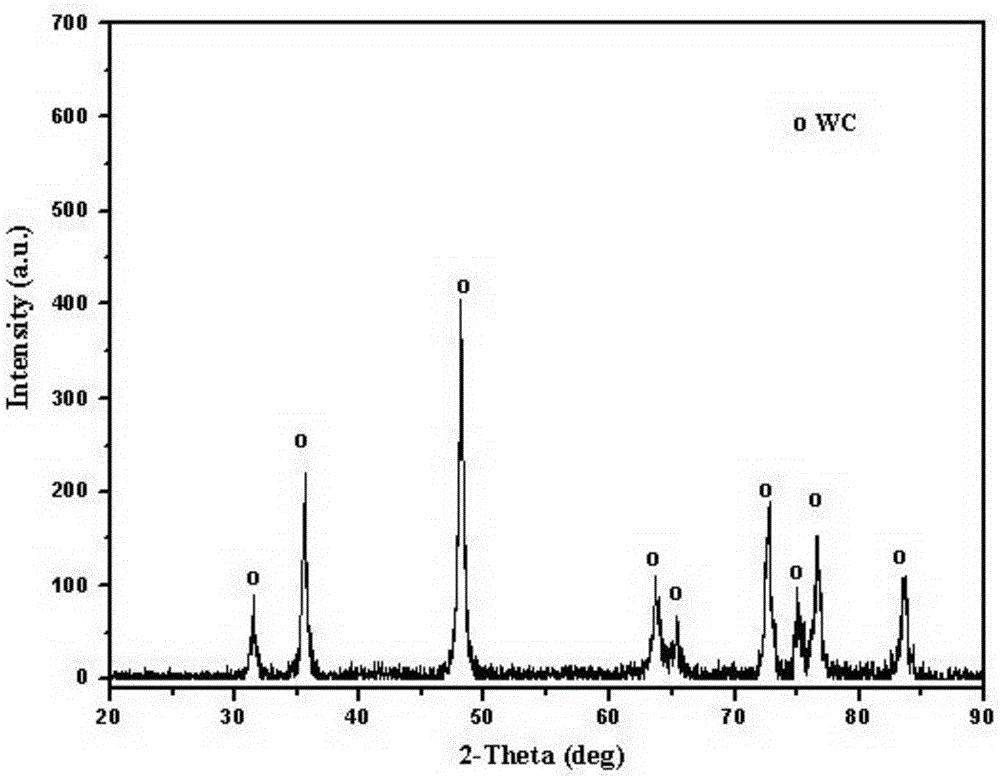

A kind of tungsten carbide cemented carbide without binder phase and its preparation method

A cemented carbide, non-adhesive technology, applied in the field of cemented carbide, can solve problems such as complex process, and achieve the effect of simple process, convenient operation and good alloy performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The invention provides a method for preparing tungsten carbide cemented carbide without a binder phase, comprising the following steps:

[0029] A) Under protective gas or vacuum atmosphere, mix tungsten and carbon and perform high-energy ball milling to obtain a mixture;

[0030] B) Under protective gas or vacuum atmosphere, sinter the mixture obtained in the above step A) to obtain tungsten carbide cemented carbide without binder phase.

[0031] All the raw materials in the present invention have no particular limitation on their sources, and they can be obtained by conventional preparation methods or purchased on the market.

[0032] The invention firstly mixes tungsten and carbon under protective gas or vacuum atmosphere, and then carries out high-energy ball milling to obtain the mixture.

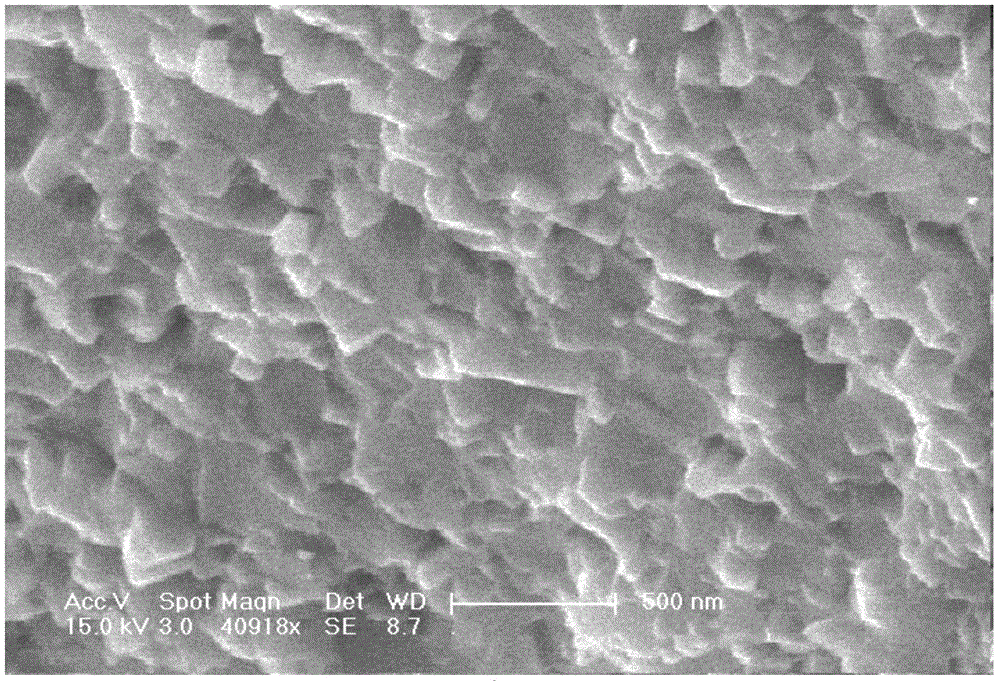

[0033] The particle size of described mixture is preferably 8~50nm, more preferably 10~30nm; The theoretical molar ratio of tungsten and carbon in the process of preparing tung...

Embodiment 1

[0050] First, mix tungsten powder with a particle size of 0.5 μm and a purity of 99.5% and carbon powder with a particle size of 0.5 μm and a purity of 99.5% at a molar ratio of 1:1.01, and control the total mass to 30 grams.

[0051] Then, under the protection of argon atmosphere, put the above-mentioned mixed powder into a ball mill jar, and then put it into a high-energy ball mill (GN-2 high-energy ball mill, Shenyang Kete Vacuum Electromechanical Equipment Factory), and the frequency of the ball mill is 900 rpm. Carry out ball milling under the condition of / minute, after ball milling 6 hours, obtain the mixture that particle size is 50nm.

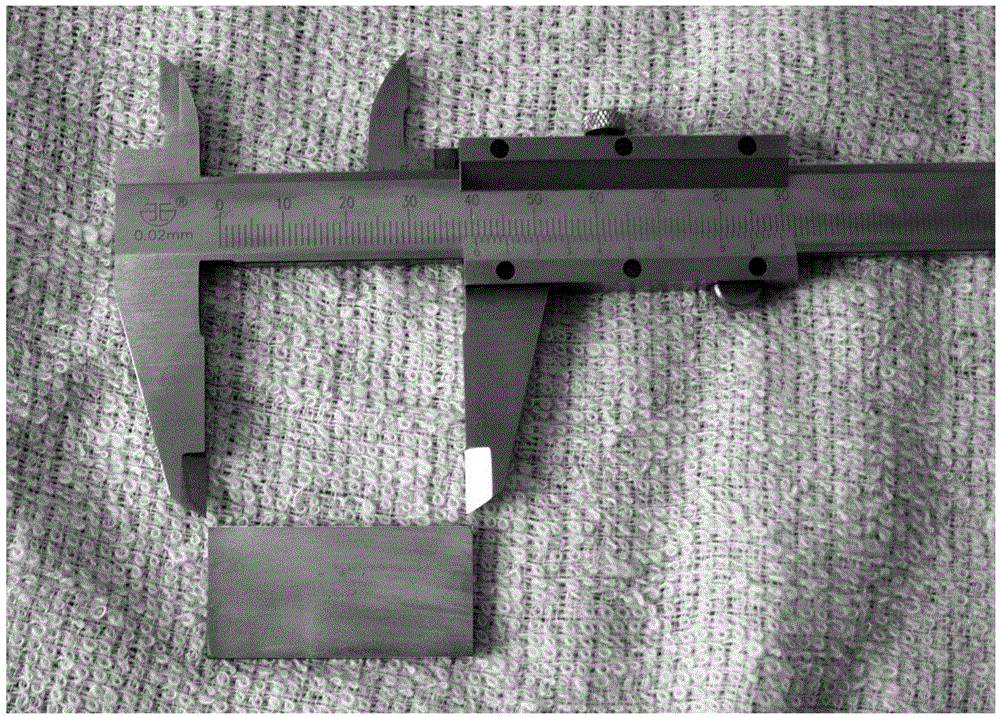

[0052] Under the protection of an argon atmosphere, the mixture obtained in the above steps was subjected to cold pressing under a pressure of 200 MPa to obtain a mixture green body. Put the above mixture green body into a graphite mold, and carry out reaction sintering in a sintering furnace (TL2000, Suzhou Tenglong Machinery Manufactu...

Embodiment 2

[0057] First, mix tungsten powder with a particle size of 1 μm and a purity of 99.5% and carbon powder with a particle size of 3 μm and a purity of 99.5% at a molar ratio of 1:1.01, and control the total mass to 30 grams.

[0058] Then, under the protection of argon atmosphere, put the above-mentioned mixed powder into a ball mill jar, and then put it into a high-energy ball mill (GN-2 high-energy ball mill, Shenyang Kete Vacuum Electromechanical Equipment Factory), and the frequency of the ball mill is 900 rpm. Carry out ball milling under the condition of / minute, after ball milling 6 hours, obtain the mixture that particle size is 50nm.

[0059] Under the protection of an argon atmosphere, the mixture obtained in the above steps was subjected to cold pressing under a pressure of 200 MPa to obtain a mixture green body. Put the above mixture body into a graphite mold, and carry out reaction sintering in a sintering furnace (TL2000, Suzhou Tenglong Machinery Manufacturing Co., ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com