Glass heat pipe LED lamp with surface provided with titanium dioxide coating

A technology of LED lamps and glass heat pipes, which is applied in cooling/heating devices of lighting devices, lighting and heating equipment, components of lighting devices, etc., can solve the problem of not containing heat transfer substrates, etc. Stable performance and improved service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

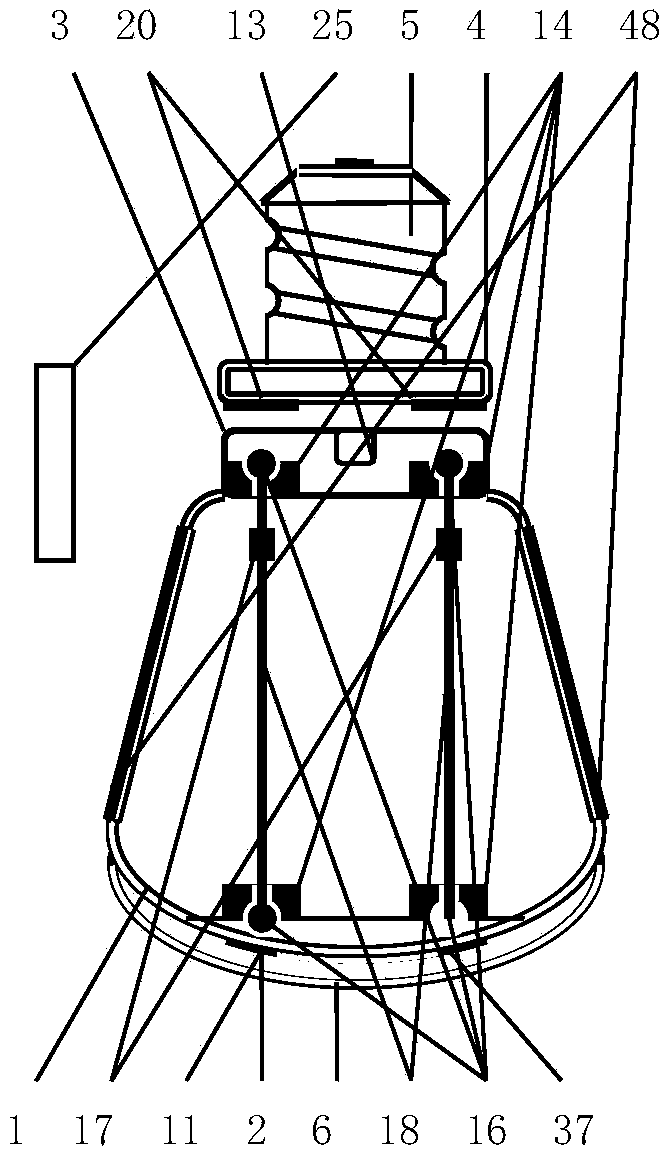

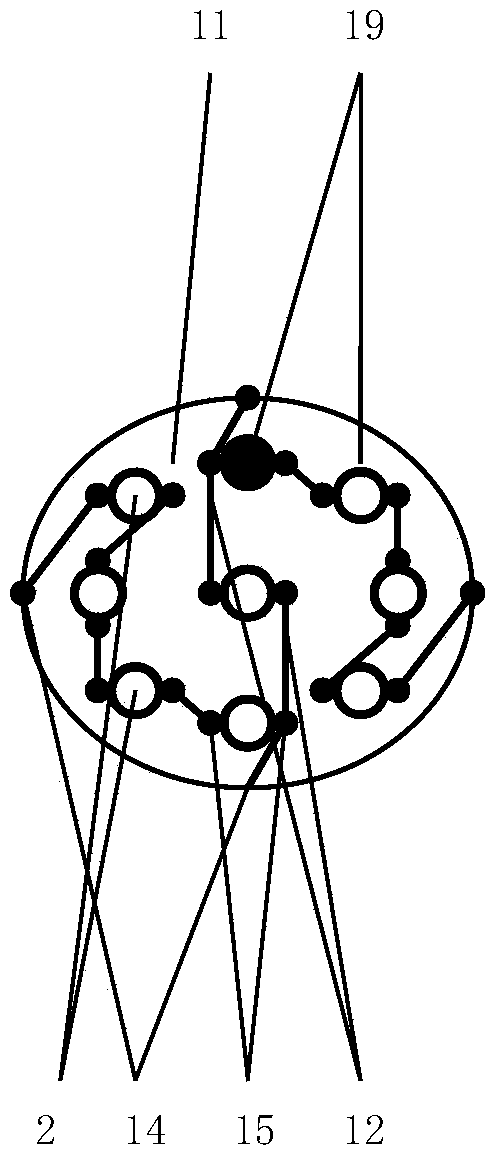

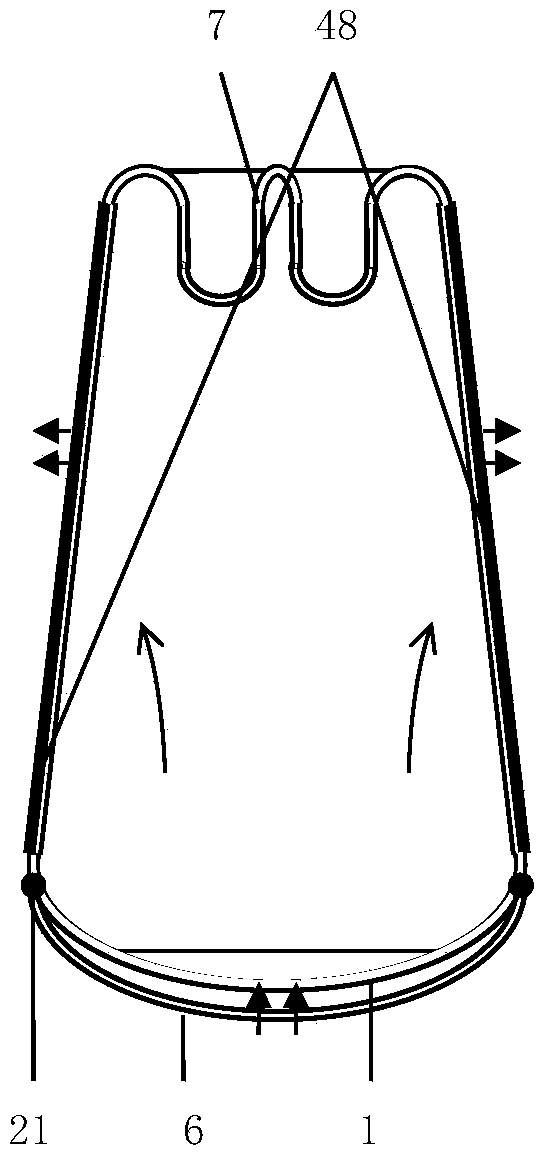

[0059] LED connection interface 15 in embodiment 1 can also refer to Figure 4 with Figure 5 Example 2.

[0060] Figure 4 with Figure 5 A second embodiment of the present invention is collectively given.

[0061] Figure 4 with Figure 5 Among them, an LED circuit board 11 is pasted on the hot end of the glass heat pipe 1 . The LED circuit board 11 is provided with a conductive circuit 12 and a cable clamping groove 14 , and the cable clamping groove 14 is clamped and connected to the cable clamping end 16 of the quick-connect cable 18 . The LED circuit board 11 is also provided with an LED hole 19 for arranging the LED 2 .

[0062] The LED connection interface 15 made on the LED circuit board 11 adopts a thin stainless steel plate on the circuit board with a thickness of 0.4 mm. A thermal insulation design is adopted between the LED connection interface 15 and the glass heat pipe 1 to reduce thermal shock and heat transfer to the glass heat pipe 1 . The contact su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com