Method for extracting lithium from low grade lithium-containing clay mineral

A lithium clay ore, low-grade technology, applied in the field of lithium extraction from low-grade lithium-containing clay ore, can solve the problems of large amount of reagents, potassium pollution of products, difficulty in collecting lithium chloride, etc., and achieve the effect of avoiding long process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further explained below in conjunction with specific embodiments.

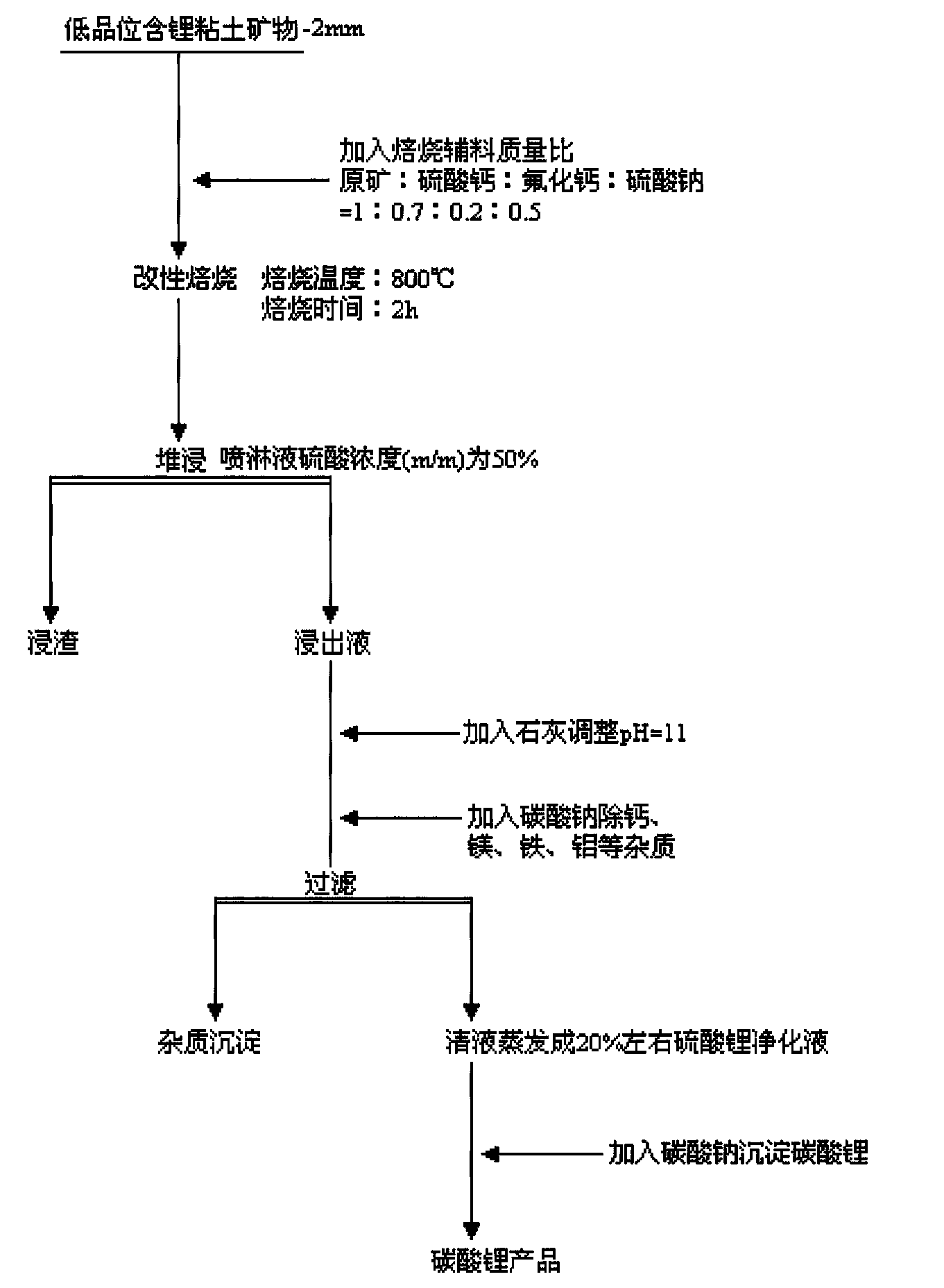

[0035] A method for extracting lithium from low-grade lithium-containing clay minerals is characterized by comprising the following steps:

[0036] Step 1, crushing low-grade lithium-containing clay ore

[0037] The lithium-containing clay ore is crushed to 2 mm.

[0038] Step two, mixing

[0039] The lithium-containing clay ore prepared in step one is added with roasting auxiliary materials and mixed uniformly. The roasting auxiliary materials include calcium sulfate, calcium fluoride and sodium sulfate, and the mass ratio is lithium-containing clay ore: calcium sulfate: calcium fluoride: sulfuric acid. Sodium=1:0.7:0.2:0.5.

[0040] Step three, roasting

[0041] Put the uniformly mixed materials in step two into the muffle furnace, adjust the temperature to 800°C, and the roasting time for 2 hours.

[0042] Step 4: Prepare sulfuric acid leaching solution,

[0043] Add concentrated sul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com