Diesel injector of integrated corona igniting device

A technology of diesel fuel injector and ignition device, which is applied in the direction of electric spark ignition controller, engine ignition, spark plug, etc., can solve the problems of high maintenance cost, low ignition efficiency, low in-cylinder compression, etc., and achieve low-emission fuel economy. , high fuel economy, high ignition efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

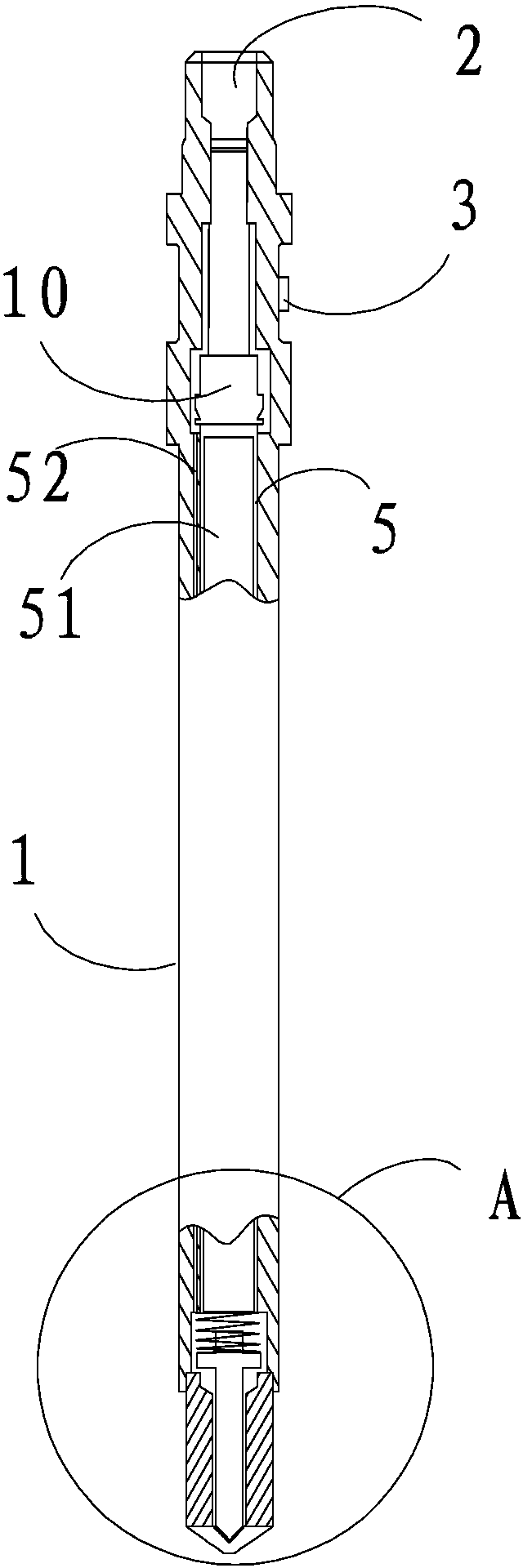

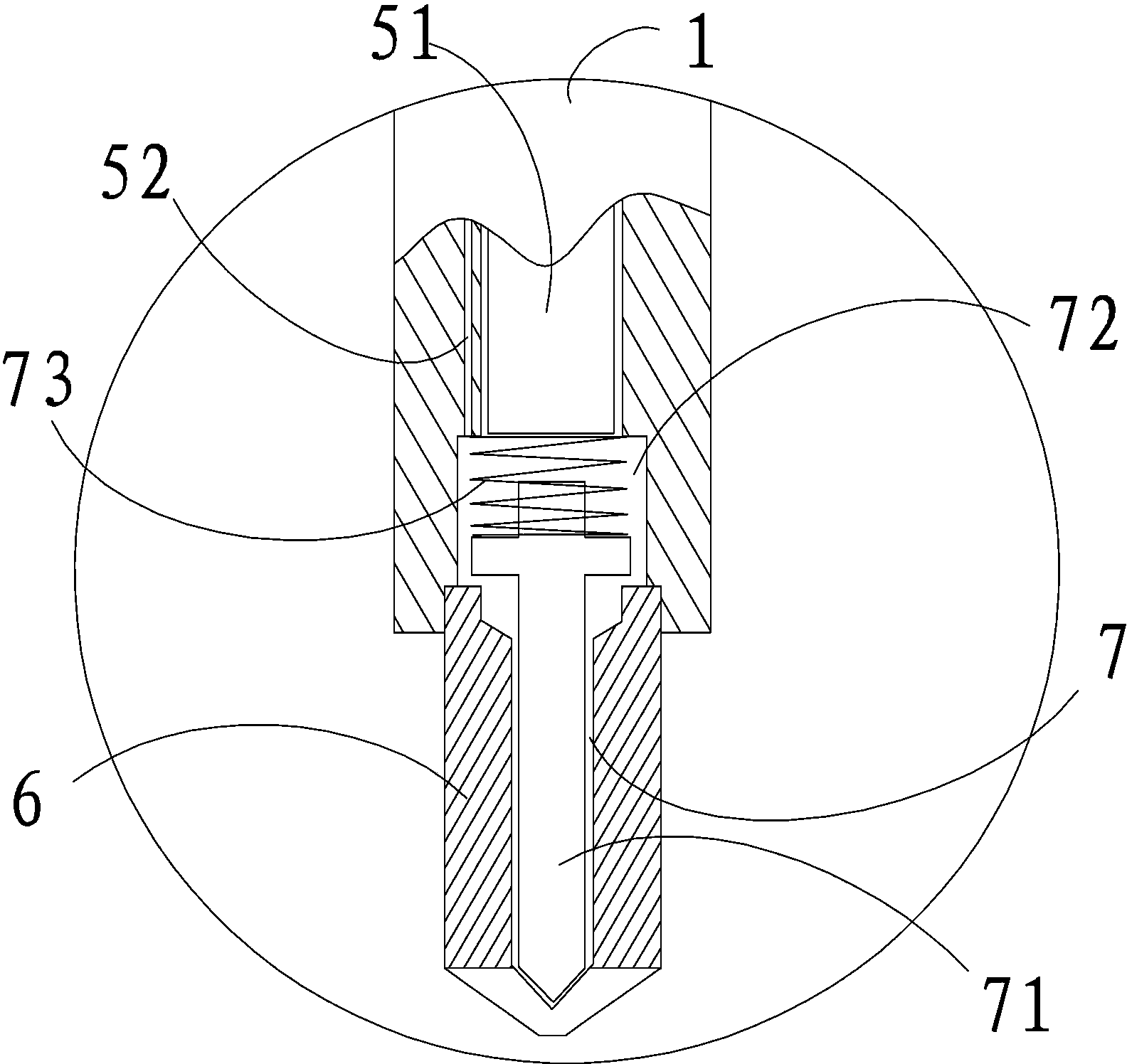

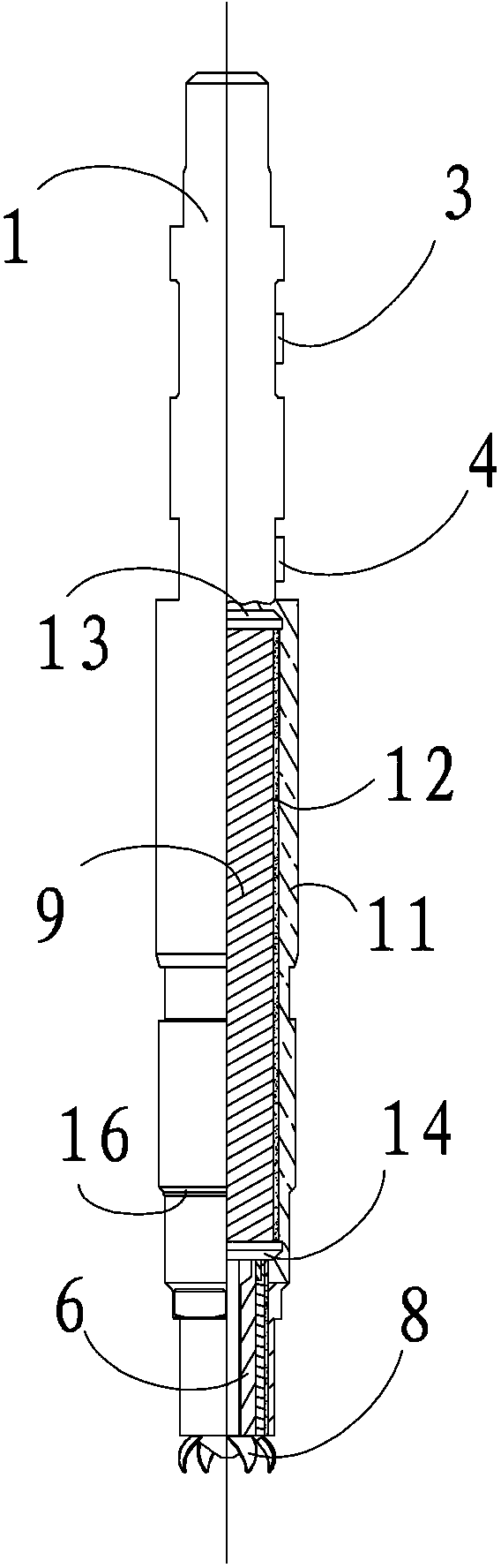

[0026] This embodiment relates to a diesel fuel injector with an integrated corona ignition device, which is applied to a dual-fuel engine with gasoline premix and diesel compression ignition. Figure 1 to Figure 4 As shown, it includes a diesel injector body 1 connected to a high-pressure fuel rail 17 not shown in the figure through a fuel inlet 2, and an injector is provided in the diesel injector body 1 below the fuel inlet 2 The solenoid valve 10, below the injector solenoid valve 10, is the plunger cavity 5 provided in the diesel injector body 1. The control line of the injector solenoid valve 10 is connected to the upper part of the diesel injector body 1. The injector solenoid valve plug-in harness 3 on the outer peripheral surface is connected with an external control unit to control the on-off between the plunger 51 and the needle valve 71. In this embodiment, for the convenience of subsequent use and maintenance of the fuel injector, the bottom of the diesel fuel inje...

Embodiment 2

[0031] This embodiment relates to a diesel fuel injector system with an integrated corona ignition device, which is applied to a dual-fuel engine with gasoline premixing and diesel compression ignition. The integrated corona in the diesel fuel injector system with the integrated corona ignition device The diesel fuel injector of the ignition device has the structure of the diesel fuel injector with integrated corona ignition device as described in the first embodiment, such as Image 6 As shown, the fuel inlet 2 of the diesel fuel injector body 1 is connected to the high-pressure fuel rail 17, the solenoid valve plug-in harness 3 of the injector is electrically connected to the ECU control unit 18, and the spark plug plug-in harness 4 is electrically connected to the control circuit 21. The control circuit 21. The energy supply mechanism 20 provides electric energy. The energy supply mechanism 20 can be an electric energy storage and conversion device, which can store electric en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com