Preparation method of fusion reactor cladding neutron and tritium breeder lithium beryllium oxide pellets

A lithium beryllium oxide and fusion reactor technology, applied in fusion reactors, thermonuclear fusion reactors, nuclear reactors, etc., to achieve the effect of solving tritium self-sustaining problems, improving competitiveness, and improving utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

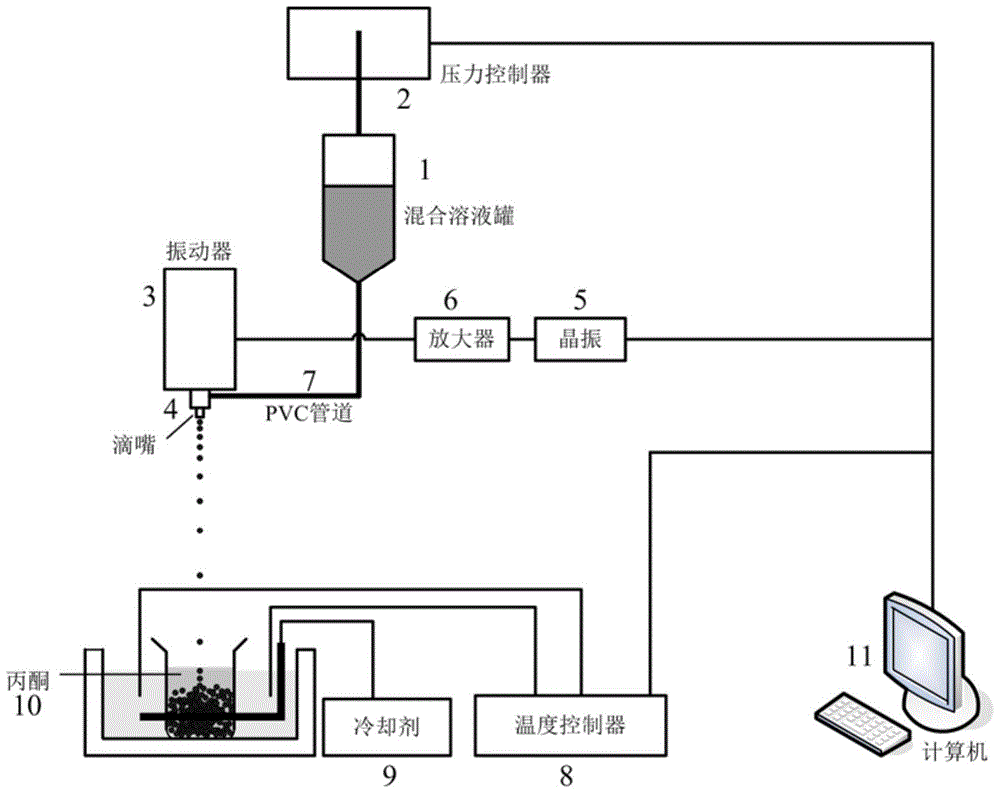

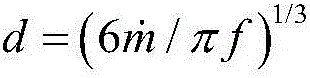

Method used

Image

Examples

Embodiment Construction

[0025] S1: lithium beryllate (Li 2 Be 2 O 3 ) Preparation of materials. Prepare quantitative high-purity lithium hydroxide (LiOH.H 2 O) and beryllium oxide (BeO) are put into the container at the ratio of Li / Bi molecular molar ratio of 1~1.05, and rotate and stir at room temperature (20℃~30℃) for 20~24 hours to mix thoroughly; after drying The gel is put into the sintering furnace, heated to 1073~1100K in an air environment, and sintered for 5~6 hours to fully carry out the solid phase reaction. The reaction formula is:

[0026] 2LiOH.H 2 O+2BeO→Li 2 Be 2 O 3 +3H 2 O

[0027] After the furnace temperature drops to room temperature, take out samples for analysis;

[0028] S2: Sample analysis of lithium beryllate materials. Take an appropriate amount of lithium beryllate sample and fully grind it into 2-3μm particles, and use XDR to analyze the crystal grain composition of the sample. The sample is composed of single-phase lithium beryllate. Using inductively coupled plasma atomic e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com