Liquid crystalline ionomer PEO/PMMA solid electrolyte and preparation method thereof

A technology of solid electrolytes and ionomers, applied in solid electrolytes, non-aqueous electrolytes, electrolyte immobilization/gelation, etc., can solve problems such as failure to meet requirements, poor low-temperature performance, and low glass transition temperature of PEO

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

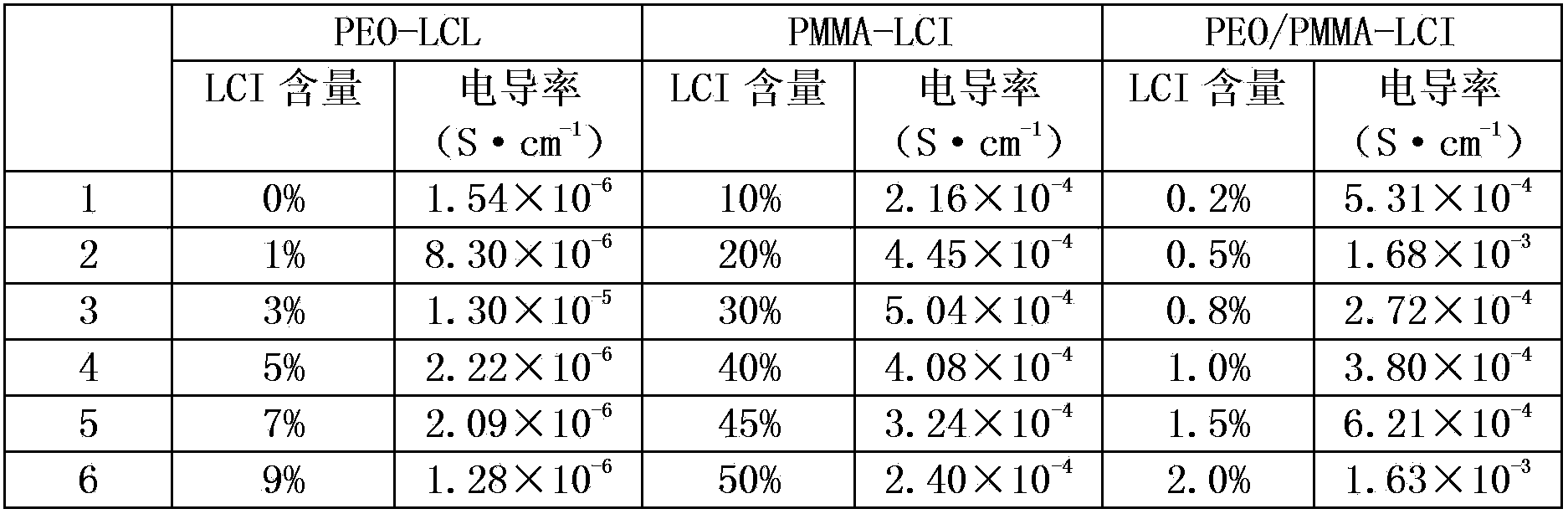

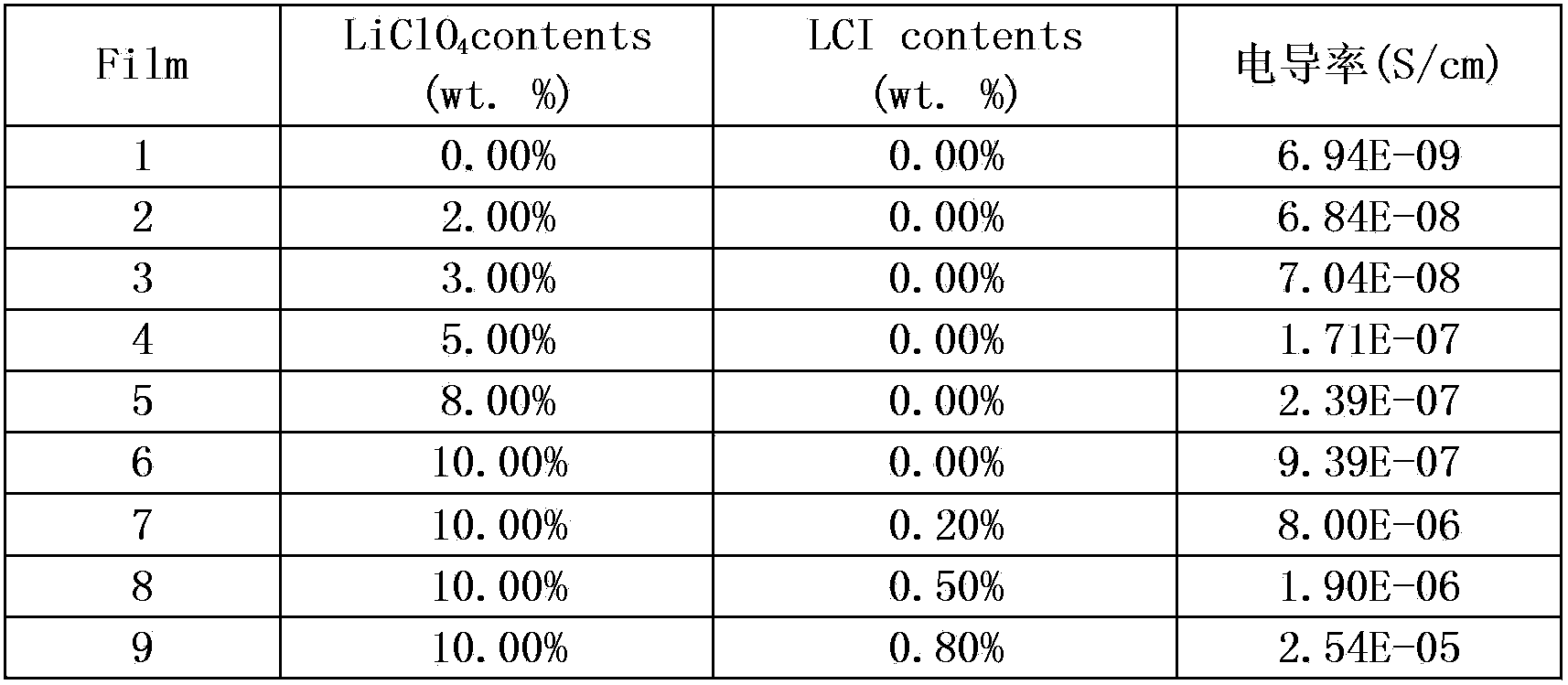

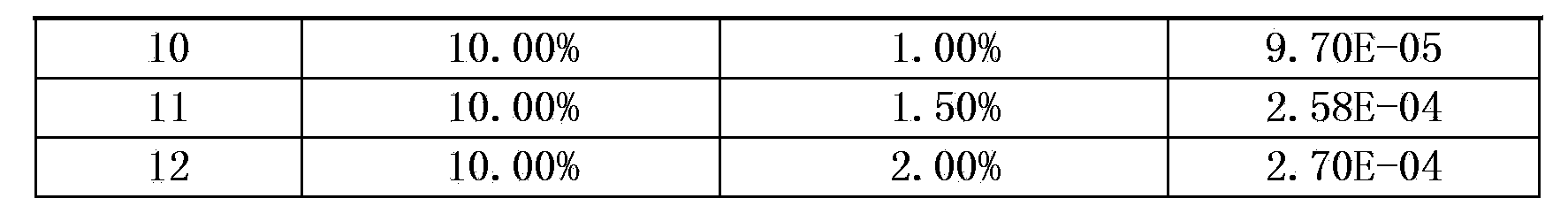

[0048] 1. PEO:PMMA is weighed by mass percentage (30-70), wherein the molecular weight of PEO is 480,000, and the molecular weight of PMMA is 90,000, and it is configured into a 30g / L dichloromethane solution, stirred, and sealed. Place it for one to two days until all the solids are dissolved to form a homogeneous solution.

[0049] 2. Weigh 10% of lithium perchlorate and 0.5% of liquid crystal ionomer, heat and stir with N-methylpyrrolidone at 80°C to dissolve, and prepare lithium perchlorate and liquid crystal ionomer with concentrations of 0.03-0.15g / L respectively And 0.003-0.03g / L solution. Liquid crystal ionomer is a main chain liquid crystal polymer containing sulfonate ions.

[0050] 3. Blend and stir the solution in 2 and the matrix solution at a volume ratio of 1:50 to obtain a gel-like liquid, scrape the film on a glass plate or a tetrafluoroethylene plate or spin the film with a spin coater, and make A homogeneous film with a thickness of 0.1-0.5 mm was obtained...

Embodiment 2

[0053] 1. PEO: PMMA is weighed by mass percentage (30-70), wherein the molecular weight of PEO is 520,000, and the molecular weight of PMMA is 100,000, which is configured into a 30g / L dichloromethane solution, stirred, and sealed. Place it for one to two days until all the solids are dissolved to form a homogeneous solution.

[0054] 2. Weigh 10% of lithium perchlorate and 0.8% of liquid crystal ionomer, heat and stir with N-methylpyrrolidone at 80°C to dissolve, and prepare lithium perchlorate and liquid crystal ionomer with concentrations of 0.03-0.15g / L respectively And 0.003-0.03g / L solution. Liquid crystal ionomer is a main chain liquid crystal polymer containing sulfonate ions.

[0055] 3. Blend and stir the solution in 2 and the matrix solution at a volume ratio of 1:50 to obtain a gel-like liquid, scrape the film on a glass plate or a tetrafluoroethylene plate or spin the film with a spin coater, and make A homogeneous film with a thickness of 0.1-0.5 mm was obtaine...

Embodiment 3

[0058] 1. PEO:PMMA is weighed by mass percentage (50-50), wherein the molecular weight of PEO is 600,000, and the molecular weight of PMMA is 110,000, and it is configured into a 30g / L dichloromethane solution, stirred, and sealed. Place it for one to two days until all the solids are dissolved to form a homogeneous solution.

[0059] 2. Weigh 10% of lithium perchlorate and 1.0% of liquid crystal ionomer, heat and stir with N-methylpyrrolidone at 80°C to dissolve, and prepare lithium perchlorate and liquid crystal ionomer with concentrations of 0.03-0.15g / L respectively And 0.003-0.03g / L solution. Liquid crystal ionomer is a main chain liquid crystal polymer containing sulfonate ions.

[0060] 3. Blend and stir the solution in 2 and the matrix solution at a volume ratio of 1:50 to obtain a gel-like liquid, scrape the film on a glass plate or a tetrafluoroethylene plate or spin the film with a spin coater, and make A homogeneous film with a thickness of 0.1-0.5 mm was obtaine...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com