An Electroconjugate Fluid Micropump

An electro-conjugate, micro-pump technology, used in electro-solid devices, fluid velocity measurement, liquid/fluid solid measurement, etc. Large size and other problems, to achieve the effect of avoiding irregular flow, compact structure and small external outline size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

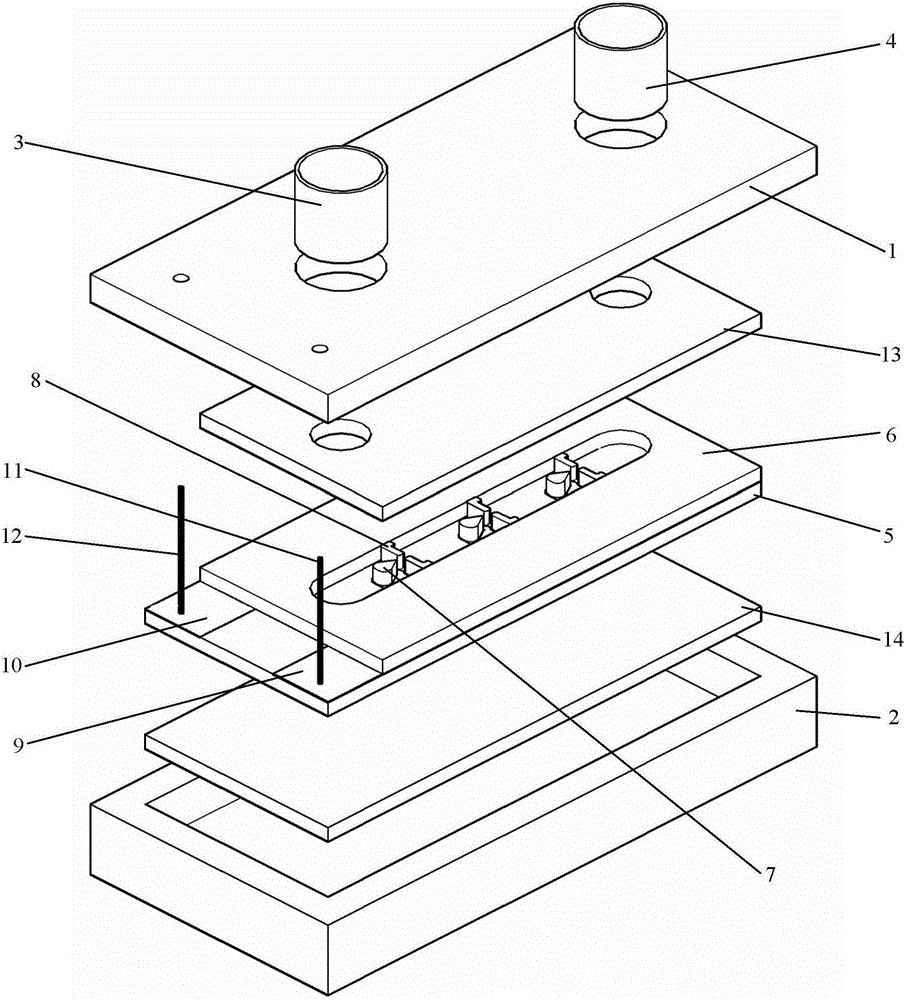

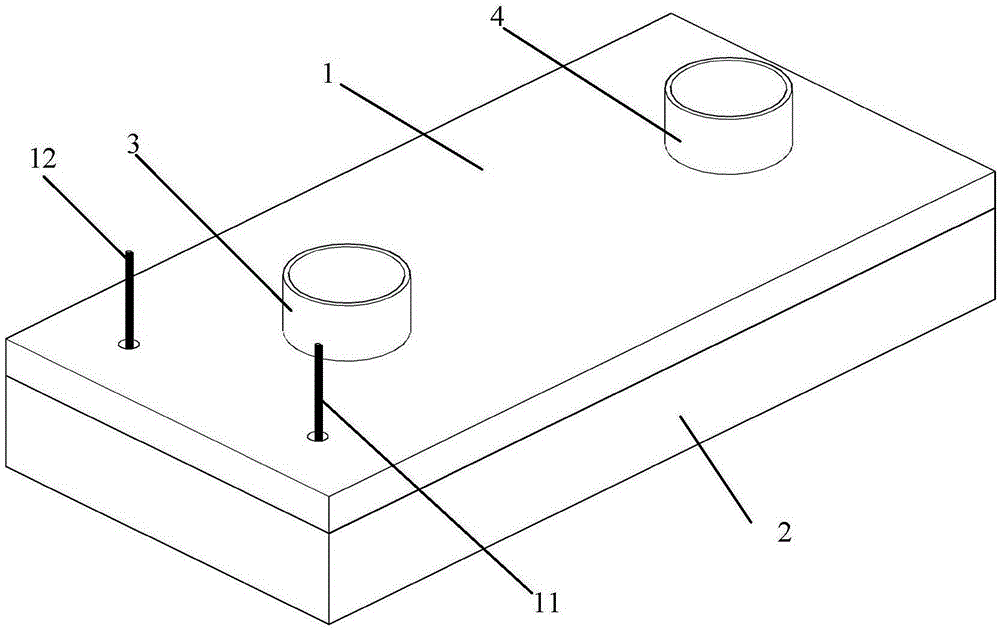

[0024] Figure 1-4 It is shown that a specific embodiment of the present invention is an electric conjugate fluid micropump, including an upper cover plate 1, a lower housing 2, a short liquid inlet pipe 3 and a short liquid outlet pipe 4, and is characterized in that:

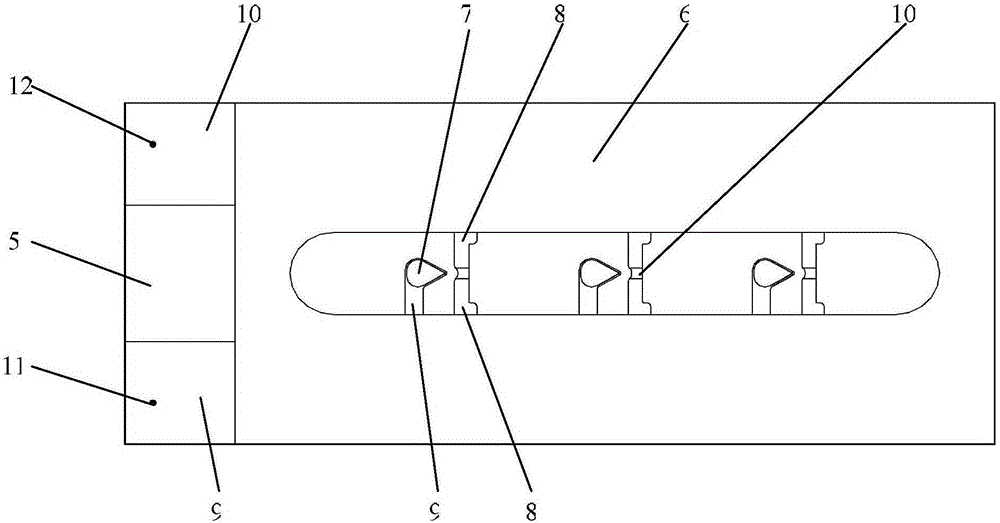

[0025] The bottom of the lower housing 2 is provided with a base plate 5, and formed on the silicon base plate 5 by ultraviolet lithography: flow channel grooves 6 with a colloidal height of 300-500um, and the flow channel grooves 6 are arranged in sequence A plurality of nickel electrode pairs, the height of the electrode pair is the same as the height of the flow channel groove 6, each electrode pair is composed of a triangular prism electrode 7 and a strip-shaped slit electrode 8, the tip of the triangular prism electrode 7 and the strip-shaped slit electrode 8 The slits are opposite, and the two sides of the strip-shaped slit electrode 8 are closely connected with the wall of the runner groove 6;

[0026]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com