A kind of single-mode optical fiber preform rod and preparation method thereof

An optical fiber preform and single-mode optical fiber technology, which is applied in the field of optical communication, can solve the problems of realizing complex refractive index profile and insufficient Ge/F co-doping process, technical difficulty of hydroxy silica raw materials, and increase of optical fiber attenuation, and reduce construction costs. and operating costs, excellent attenuation performance, and the effect of reducing water peaks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

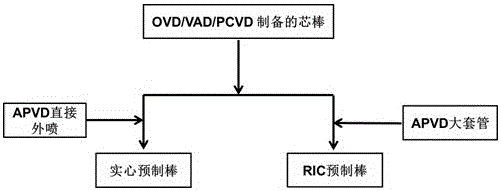

Method used

Image

Examples

Embodiment 1

[0034] The preform described in Example 1 includes two main parts: an optical fiber core rod prepared by PCVD method and a large casing made of hollow natural quartz sand material prepared by APVD method. The optical fiber core rod and large casing are assembled by ROD IN Cylinder method.

[0035] The core rod of the optical fiber prefabricated rod comprises a core layer, a first inner cladding layer and a second inner cladding layer. The optical fiber core layer prepared by PCVD is composed of quartz glass doped with fluorine and germanium: there are three cladding layers outside the core layer. The first inner cladding closely surrounds the core layer, which is made by the same PCVD deposition method as the core layer; the second inner cladding is composed of fluorine-doped OVD quartz glass; the third cladding is the outer cladding, which closely surrounds all of the second inner cladding layered.

[0036] The large casing prepared by the APVD process is prepared using four...

Embodiment 2

[0046] The optical fiber preform described in Example 2 includes two parts: the optical fiber core rod prepared by the PCVD method, and then using different grades of natural quartz sand materials, the core rod is directly sprayed on the core rod to form a preform forming body by the APVD method, and then externally The sprayed preformed body is subjected to vitrification treatment, and the surface of the preformed rod is machined after treatment to make the surface of the preformed rod smooth and the geometric parameters of the preformed rod uniform.

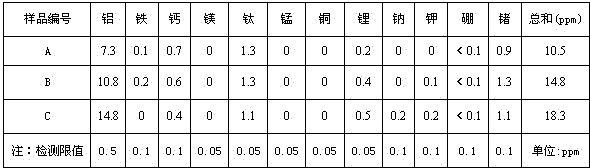

[0047] Table 4 shows the impurity content of the natural quartz sand used in this example.

[0048] Table 4 Analysis of the impurity content of the raw materials for the preparation of the hollow large casing by APVD

[0049]

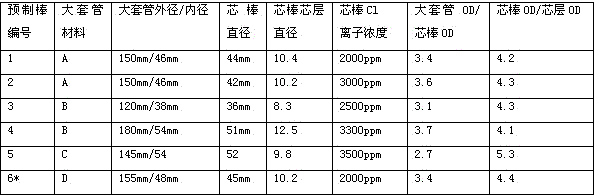

[0050] Table 5 shows the parameters of two optical fiber preforms with different specifications and composition.

[0051] Table 5 Parameters of each component of optical fiber preform

[0052]

...

Embodiment 3

[0057] The preform described in Example 3 includes two parts: the optical fiber core rod prepared by the PCVD method and the large casing of the hollow natural quartz sand material prepared by the APVD method, and the optical fiber core rod and the large casing are assembled into an optical fiber by the Rod In Cylinder method Preform.

[0058] The core rod of the optical fiber preform includes a core layer, a first inner cladding layer, and a second inner cladding layer. The optical fiber core layer prepared by PCVD is composed of quartz glass doped with fluorine, germanium and other dopants: there are three cladding layers outside the core layer. The first inner cladding closely surrounds the core layer, which is made by the same PCVD deposition method as the core layer; the second inner cladding is composed of fluorine-doped OVD quartz glass; the third cladding is the outer cladding, which closely surrounds all of the second inner cladding layered.

[0059] The large casin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com