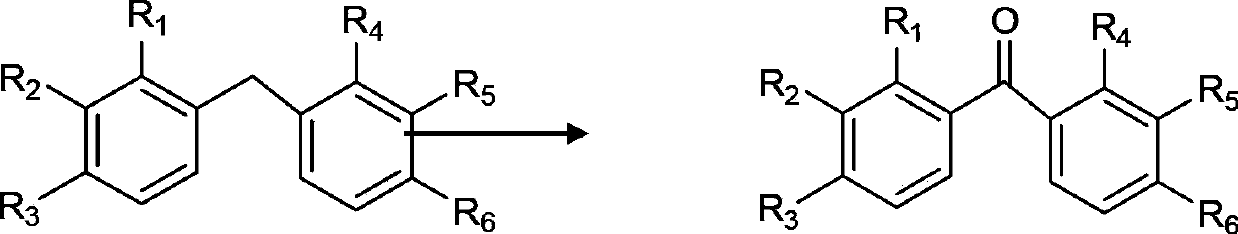

Method for preparing diphenyl ketone compound

A technology for benzophenones and compounds is applied in the field of preparing benzophenone compounds, which can solve the problems of low catalyst stability, cumbersome preparation process, low catalyst activity, etc., and achieves broad commercial application value, simple preparation and selection. high sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

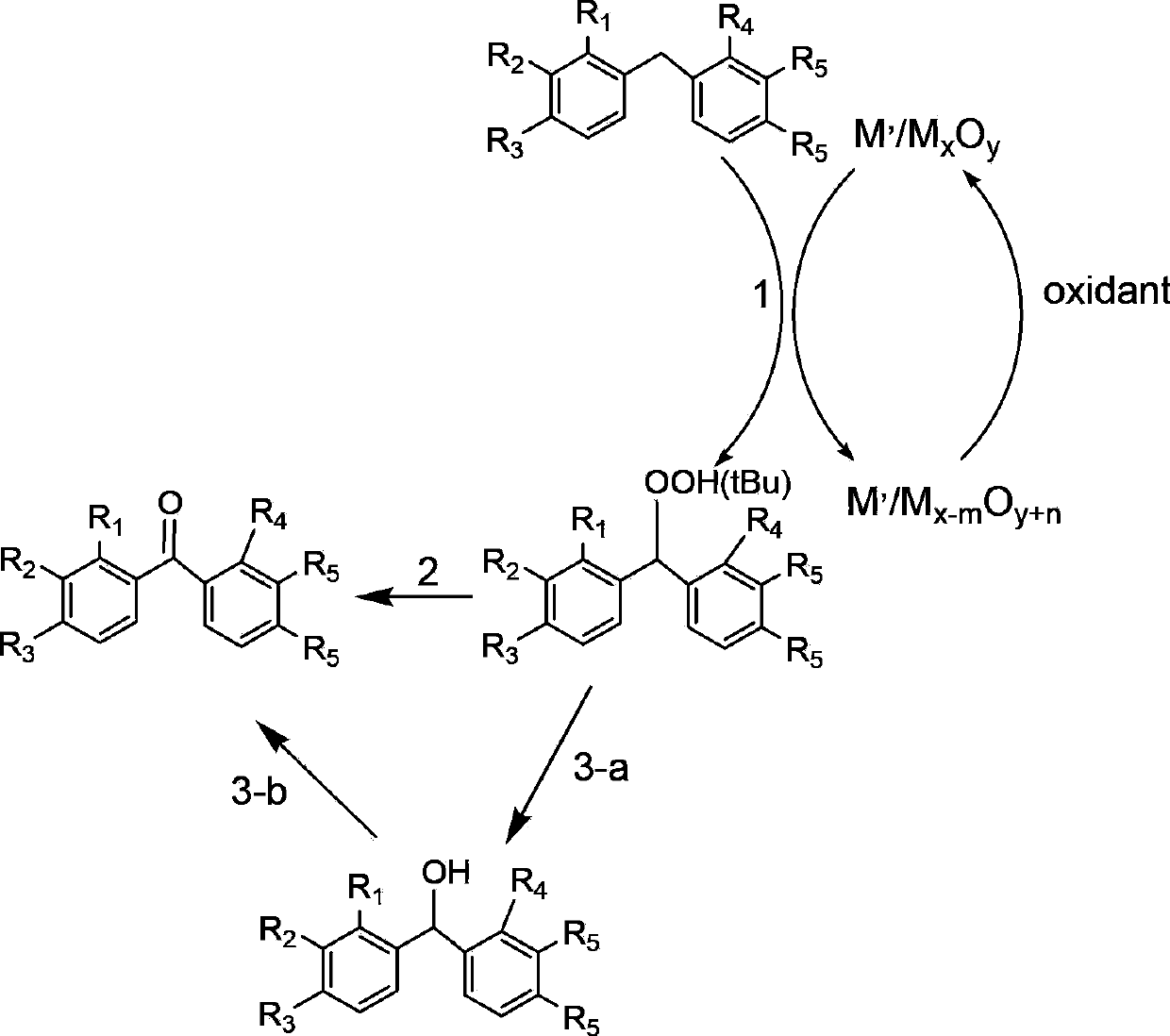

Method used

Image

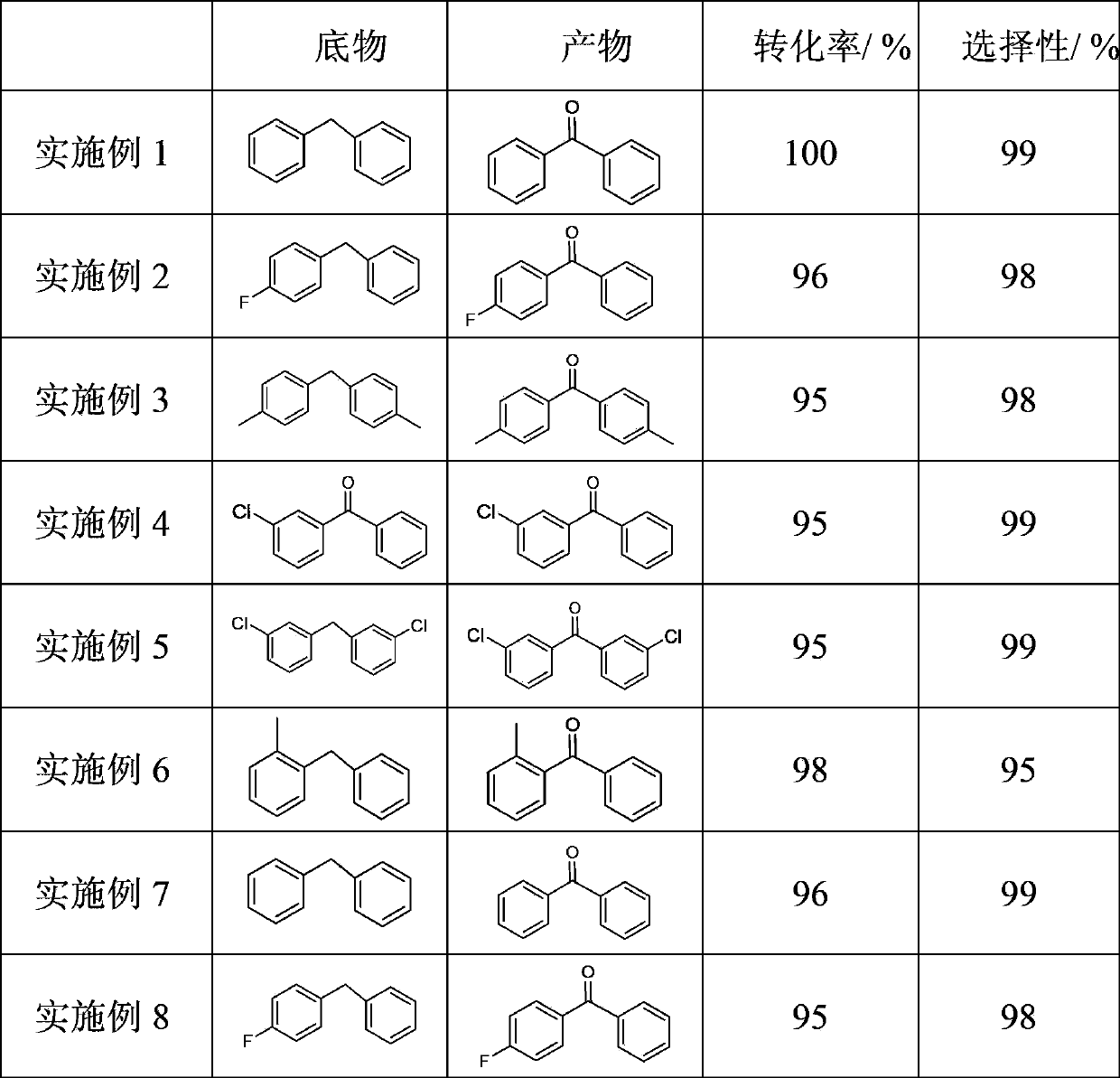

Examples

Embodiment 1

[0017]In a 250ml round bottom flask, add 1mmol of substrate, 1.2g of 30% hydrogen peroxide, and weigh 0.3g of 5wt% Pt / MoO 3 The reaction was catalyzed, and 100ml of acetic acid was added, and the reaction was refluxed and stirred at 120°C for 10h. After the reaction was completed, the product was detected by chromatography. The yield of the product is shown in Table 1

Embodiment 2

[0019] In a 250ml Teflon-lined reactor, add 0.5mmol substrate and 1.5mmol tert-butyl hydroperoxide respectively, and weigh 0.2g 2.5wt% Co / CeO 2 The reaction was catalyzed, and 100ml of pyridine was added, and the reaction was stirred at 100°C for 20h. After the reaction was completed, the product was detected by chromatography. The yield of the product is shown in Table 1

Embodiment 3

[0021] In the reactor of PTFE lining of 250ml, add 1.5mmol substrate respectively, 6mmol cumene hydroperoxide, take by weighing 0.7g 5wt% Cu / MO-V-O catalyze this reaction, and add 100ml acetonitrile, at 150 Stir the reaction at ℃ for 18h. After the reaction is over, the product is detected by chromatography. The yield of the product is shown in Table 1

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com