Electricity-insulation heat-conduction powder and material, and preparation methods thereof

An insulating and heat-conducting, powder technology, applied in insulators, heat-exchange materials, chemical instruments and methods, etc., can solve the problems of impractical heat conduction, expensive diamond cost, difficult processing, etc., and achieve the effect of high thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

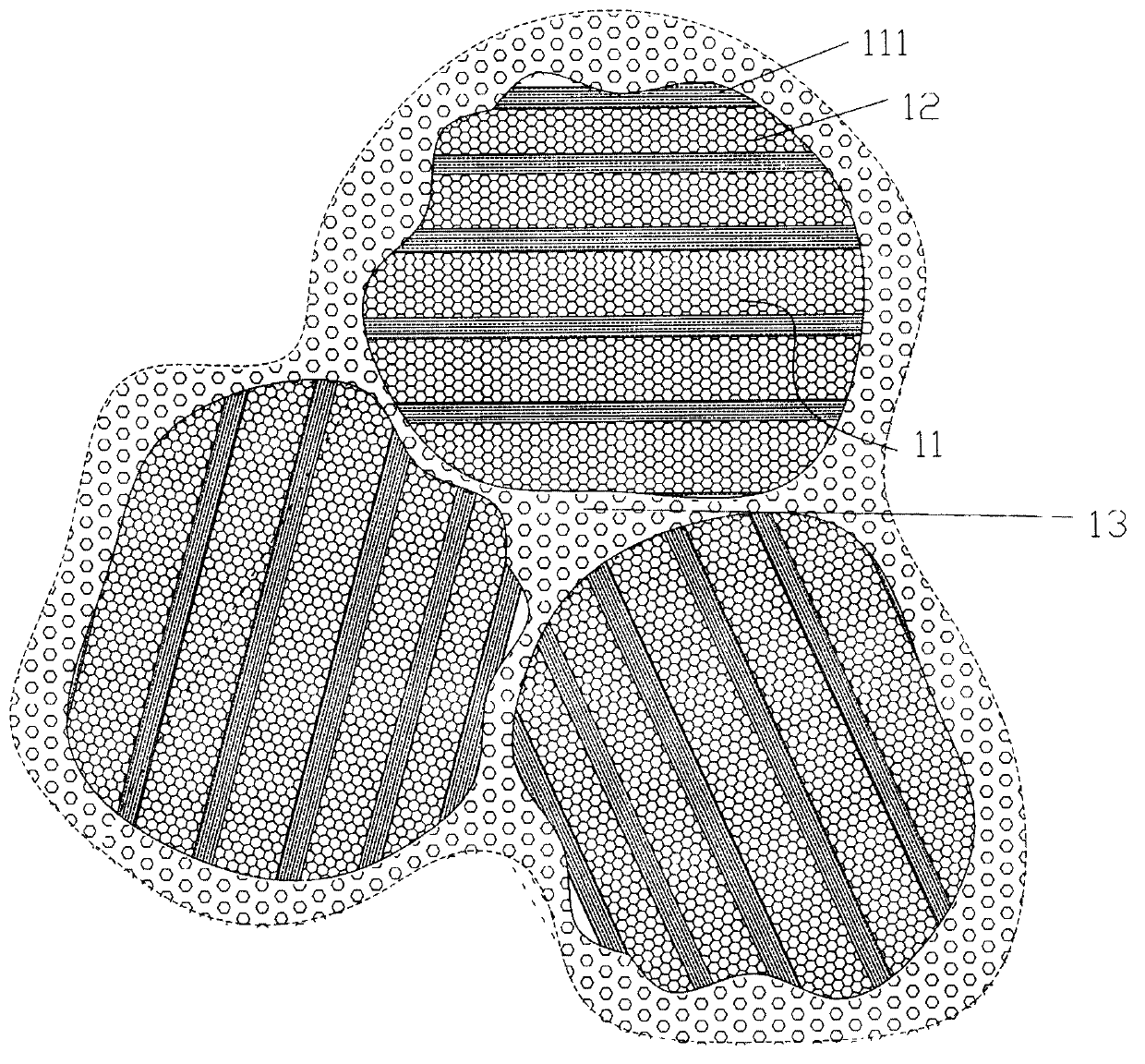

[0026] This embodiment provides an insulating and heat-conducting powder. The insulating and heat-conducting powder includes graphite intercalation composite particles in the micron size range of 50 μm to 100 μm. The microstructure of the graphite intercalation composite includes a plurality of graphite crystals. grains, nano-scale thermally conductive insulating metal oxides distributed between the carbon atomic layers of a single graphite grain and in the gap between two graphite grains, and the graphite grain is the matrix, such as figure 1 As shown, the gap between the carbon atom layers 111 of a single graphite grain 11 is filled with nano-scale aluminum oxide 12, the average thickness of the nano-scale aluminum oxide is 0.05nm, and it is distributed in the gap 13 between two graphite grains. The average thickness of the nanoscale alumina is 10nm (not shown in the figure), and the graphite intercalation composite is filled with In addition to nano-scale alumina, the perip...

Embodiment 2

[0030] This embodiment provides an insulating and thermally conductive powder, which includes micron-sized graphite intercalation composite particles and micron-sized alumina powder, and the average particle diameter of the graphite intercalation composite particles is 10 μm. The average particle size of the micron-sized alumina powder is 1 μm, and the microstructure of the graphite intercalation composite includes multiple graphite grains, distributed between the carbon atomic layers of a single graphite grain, and distributed between two graphite grains. Interstitial nanoscale heat-conducting insulating metal oxide, the graphite grains as the matrix, such as figure 1 As shown, the gap between the carbon atom layers 111 of a single graphite grain 11 is filled with nano-scale aluminum oxide 12, the thickness of the nano-scale aluminum oxide 12 is 0.34nm, distributed in the gap 13 between two graphite grains The average thickness of the nanoscale alumina is 100nm (not shown in ...

Embodiment 3

[0034] This embodiment provides an insulating heat-conducting powder, which includes nano-scale graphite intercalation composite particles and nano-scale titanium oxide, the average particle diameter of the graphite intercalation composite particles is 500nm, the graphite The microstructure of the intercalation composite is a nanoscale thermally conductive insulating metal oxide that includes a plurality of graphite grains, is distributed between the carbon atomic layers of a single graphite grain, and is distributed in the gap between two graphite grains, and the graphite grains are matrix, such as figure 1 As shown, the gap between the carbon atom layers 111 of a single graphite grain 11 is filled with nano-scale titanium oxide 12, the average thickness of the nano-scale titanium oxide is 0.08nm, and it is distributed in the gap 13 between two graphite grains. The average thickness of the nanoscale titanium oxide is 50nm (not shown in the figure), and the graphite intercalat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com