Due to the inability to solve the

assembly problem of herringbone inner ring gear planetary transmission, the current planetary transmission field has to use straight tooth or small

helix angle

helical tooth inner ring gear. For large

diameter herringbone inner ring gear, it is limited to the maximum

processing diameter limit of equipment

processing. It is even more difficult to process. Even if the integral herringbone ring gear is processed by a super-large

machine tool, it is difficult to complete the entire planetary transmission

assembly. The sun gear, planetary gear, and ring gear are all integral herringbone gears, which will not be able to be assembled.

Segmental

processing of large-diameter herringbone inner ring gears is an inevitable trend in the development of large-scale

herringbone gear planetary transmissions. The inner ring gear still cannot be machined. The diameter of the integral ring gear depends on the maximum machining diameter of the

gear shaping machine tool. Small equipment cannot be used to process large workpieces, and the processing capacity of the

machine tool can be fully utilized.

Once one tooth or a few teeth of the integral ring gear fail, the ring gear has to be replaced as a whole, which consumes a lot of financial and

material resources In addition, when two

helical inner ring gears are combined and connected, it is difficult to ensure that the two ring gears in the left and right directions have good alignment. Each tooth of the entire ring gear has a relatively

large tooth alignment in the left and right directions. error

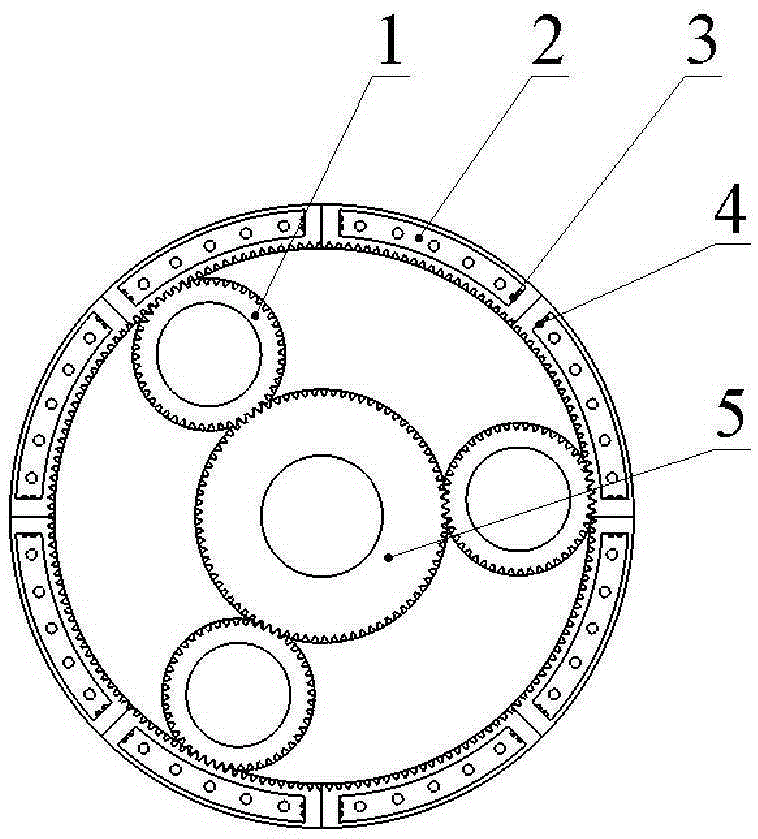

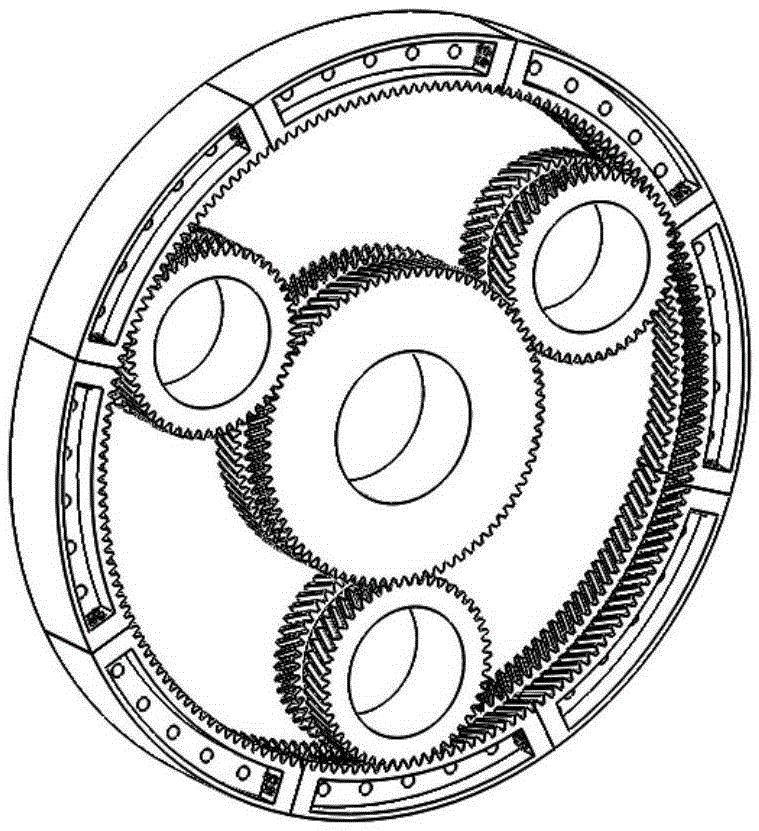

[0005] At present, the segmental

design technology of the herringbone inner ring gear has also appeared. The

patent document [CN101793308A] discloses an invention method of a herringbone planetary

reducer. The key technology is the segmented herringbone inner ring gear. The assembly problem of the planetary transmission also solves the manufacturing problem of the large-diameter internal ring gear. It is possible to use a small

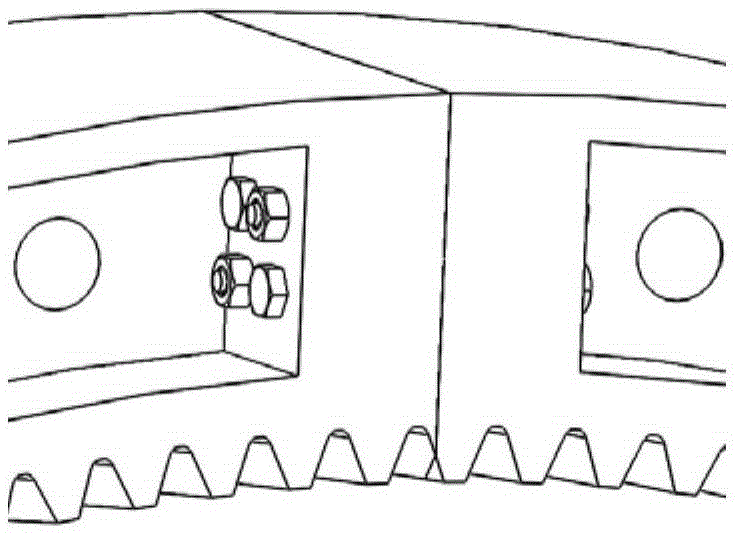

machine tool to process the large-diameter internal ring gear. It is indeed a major breakthrough and innovation in technology. The method of segmenting both in the direction and the axial direction, the left-handed and right-handed gear teeth are divided in the axial direction, and then combined with bolts, so there must be a large error in the neutrality, especially the two tooth segments on the radial circumference The connection is made by

punching holes on the inclined surface and connected by bolts. It is very difficult to process the holes on the inclined surface, especially the positioning is difficult. The positioning of the inclined holes is extremely inaccurate. The holes are particularly easy to deviate, and the position and shape accuracy of the holes are difficult to guarantee. , and the step hole is still processed, the thread is processed in the inner hole, and the positioning sleeve is also installed. How to press the positioning sleeve at the bottom of the

deep hole is also very difficult to install the positioning sleeve. Conventional techniques and methods cannot be solved at all. Sleeve, how to ensure the accurate position of the press-in, how to measure, how to ensure that the pressed-in positioning sleeve is not deformed, the space of the inclined hole is extremely narrow, there is not enough space for a

wrench to tighten the bolt, and the problem of how to tighten the bolt has become a problem. Due to the limitation of the space position and structure of the inclined surface drilling, only one hole can be processed on each side of the inclined surface of the two tooth segments, and only two bolts are used to connect the large-diameter inner ring gear, which has huge hidden dangers in terms of strength and rigidity, and this kind of The inclined-plane drilling method destroys the integrity of the surface on both sides of the ring gear, causing

stress concentration, and there will be many sharp

metal corners, which are extremely sharp, which may easily cause scratches on the operator and cause safety accidents. The two-tooth section of this technology The connection accuracy is guaranteed by the inclined hole. From this, it can be seen that the assembly accuracy of the combined connection of the two

tooth segment inclined surfaces cannot be guaranteed. The bolt plays the role of connection, and the positioning function is extremely limited.

As a precision transmission part, gears are very sensitive to errors. In addition, it is difficult to ensure that the two ring gears in the left and right rotation directions are well aligned when the separate single-section inner ring gear is combined axially and radially. Each tooth has a

large tooth alignment error in the left and right directions, and the radial direction and the circumferential direction cannot be accurately positioned, which will generate a large

axial force and affect the stability of the transmission, etc., thus losing the herringbone teeth some of the advantages

And the planetary transmission principle announced by the

patent document [CN101793308A] is the most common 2K-H planetary transmission. The technical solution adopted is that the ring gear is fixed and the planetary carrier rotates, so that the planetary gear and the planetary gear bearing not only rotate around their own axis , it has to rotate with the planetary frame to perform revolution, so that it bears huge

centrifugal force, and the supporting bearing of the planetary wheel is very easy to fail; because the planetary wheel and the planetary wheel bearing rotate with the planetary frame all the time, the position in space is not fixed and changes all the time, so It is impossible to use the fixed-point pressure

lubrication method to lubricate and cool the planetary gear and planetary gear bearings. It can only be periodic intermittent

lubrication. Because the bearings run at high speed and there is no lubricating oil for cooling at all times, it is easy to cause the bearings to heat up and burn. Bad, the planetary gear is also prone to various forms of gear failure due to poor

lubrication and heat dissipation

Login to View More

Login to View More  Login to View More

Login to View More