Flexible monocrystalline silicon solar cell manufacturing technique

A technology for solar cells and production processes, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of difficult to meet the manufacturing process of flexible solar panels, inconvenient to carry, fragile and vulnerable, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

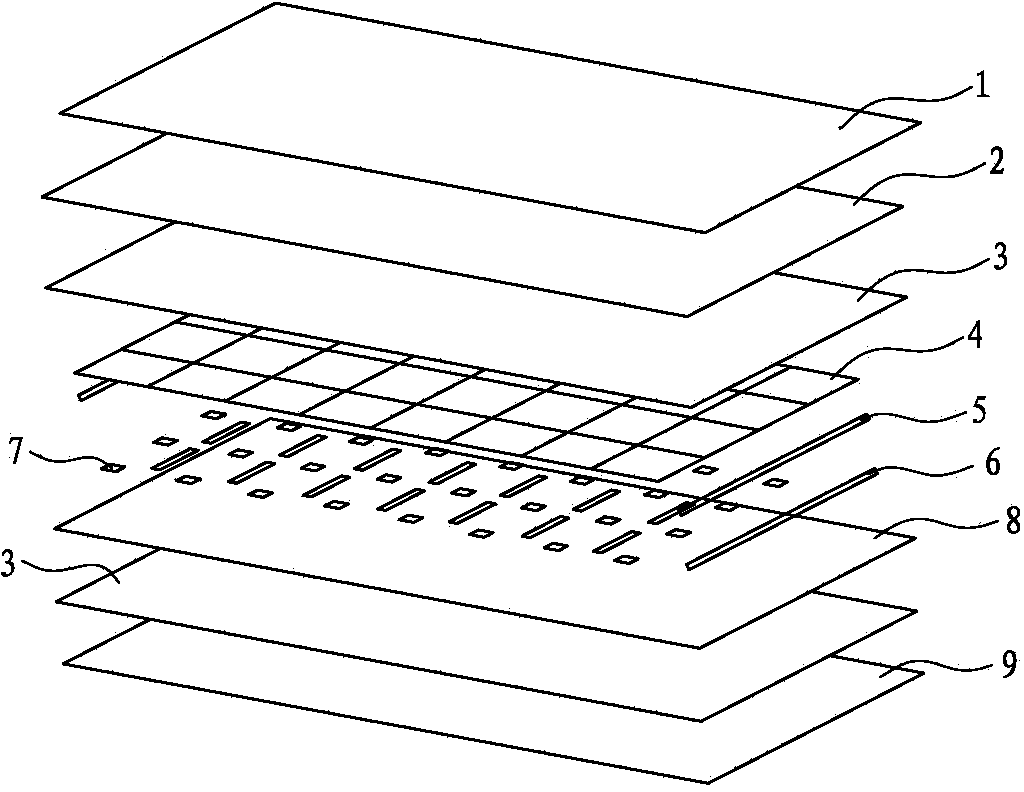

[0009] figure 1 It is a kind of flexible monocrystalline silicon solar cell to be produced in the present invention, which includes PET layer 1, front film layer 2, EVA layer 3, cell sheet 4, bus bar 5, EPE tape 6, positioning tape 7, glass fiber mat 8 , Backplane layer 9, double-sided foam glue, junction box.

[0010] The present invention is a kind of flexible monocrystalline silicon solar cell production technology, and it comprises the following steps:

[0011] 1. Silicon wafer sorting: Detect and classify the electrical properties of the cells 4, optimize the arrangement of the components; screen the electrical properties of the cells 4, and check the appearance of the cells 4 such as color difference, chipping, hidden cracks, and missing corners screening;

[0012] 2. Wafer splicing: arrange and distribute the cells 4 according to the design shape and cut the bus bars;

[0013] 3. Silicon wafer welding: connect the battery slices 4 in series and parallel to make the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com