Electroluminescent device

A technology of electroluminescent devices and light-emitting layers, which is applied in the direction of electric solid-state devices, electrical components, semiconductor devices, etc., and can solve problems such as low lifespan and slow switching speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

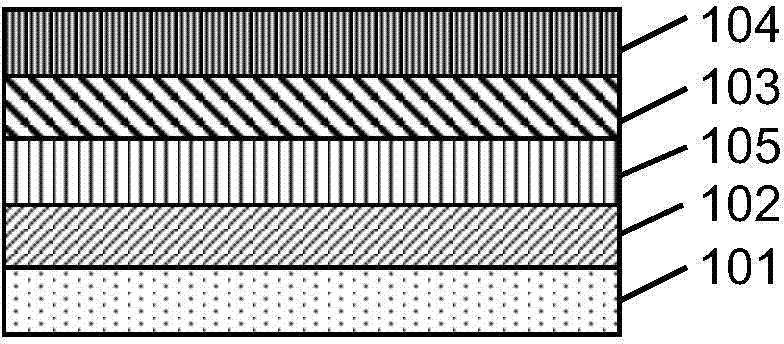

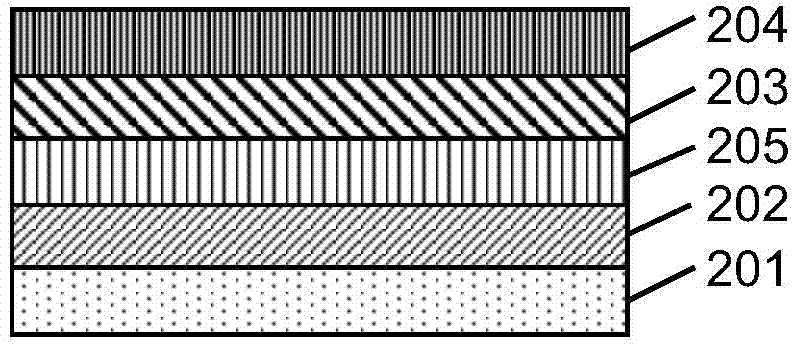

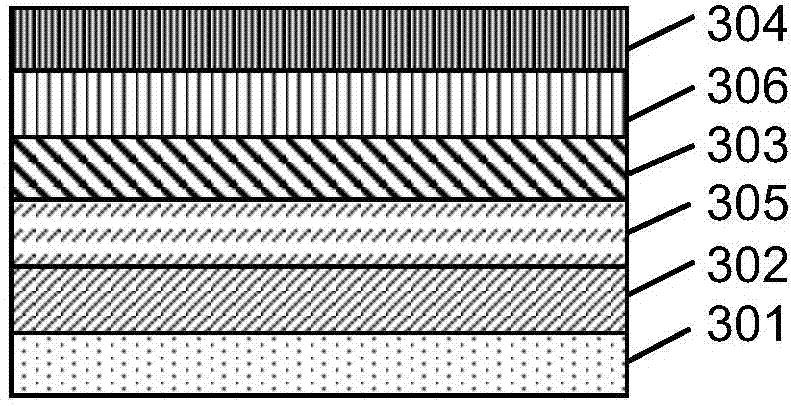

Image

Examples

Embodiment Construction

[0165] 1. Preparation of Cathode / FTL

[0166] The present invention uses 50nm ITO as the cathode. The ITO conductive glass substrate is first cleaned with various solvents (chloroform→acetone→isopropanol), and then treated with ultraviolet ozone plasma. Next, in a monolithic reactor, about 8 nm of TiN (TiCl 4 / NH 3) onto ITO by chemical vapor deposition. Hafnium oxide zirconia solid solution (Hf 0.5 Zr 0.5 o 2 ) were deposited on TiN by thermal atomic layer deposition (ALD). The ALD process was based on commercially available (Aldrich) organometallic precursors tetrakis-(ethylmethylamino)-(hafnium / zirconium) (TEMAH and TEMAZ) with ozone. The content of zirconia and hafnium oxide in the solid solution can be determined by changing the period ratio of the precursors. The thickness of the film is set to about 9nm by controlling the super period number of ALD. Then, the hafnium oxide zirconia solid solution film was heat-treated at 500°C for 5 minutes. Hf so prepared 0.5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com