Single-layer film-loaded four-layer substrate microstrip-microstrip interconnect structure

An interconnection structure, single-layer film technology, applied in the direction of connecting devices, electrical components, circuits, etc., can solve the problems of complex interconnection structure and affecting circuit performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] Below in conjunction with accompanying drawing, the present invention is further explained:

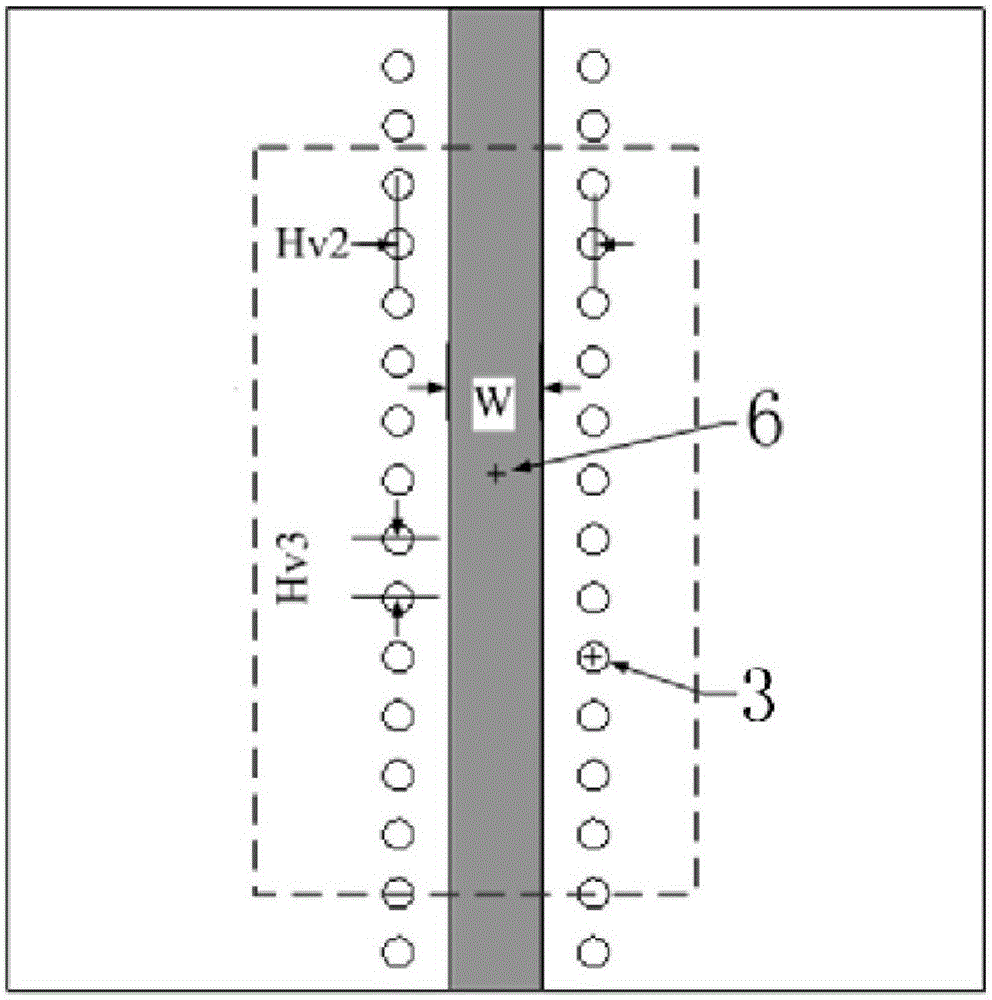

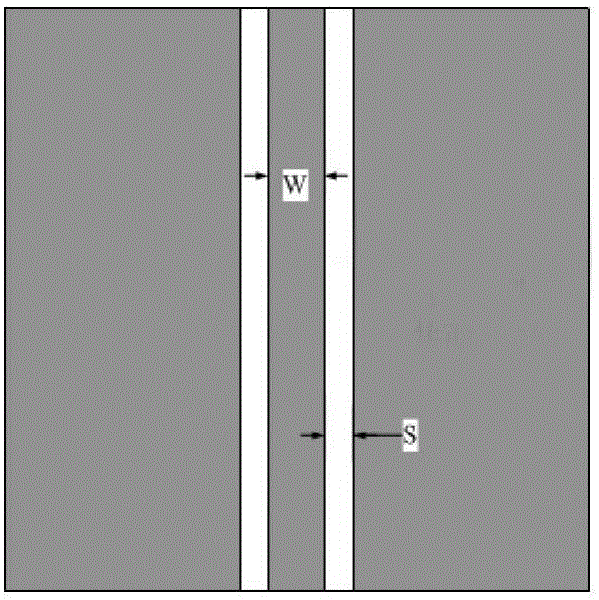

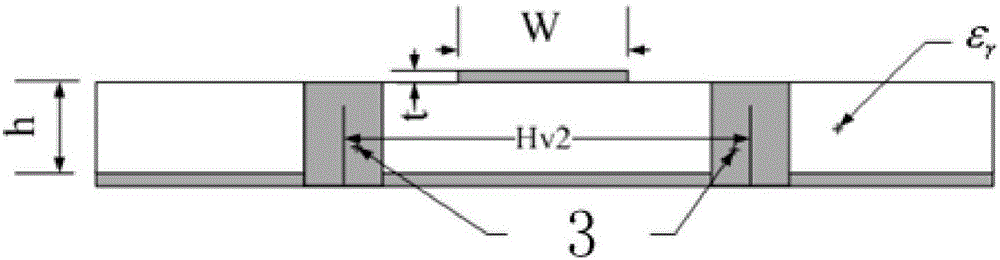

[0046] Firstly, design the quasi-grounded coplanar waveguide according to the general design method of the grounded coplanar waveguide, such as Figure 1a Shown is the top view of the ground-like coplanar waveguide, the center is the microstrip line 6, the line width is W, the two sides of the microstrip line are metal vias, and the distance between the two metal vias 3 is Hv2, and its structure can be equivalent For such Figure 1b A grounded coplanar waveguide is shown, where W is the line width and S is the clearance from the ground plane. Figure 2 is a cross-sectional view of a quasi-grounded coplanar waveguide and a coplanar waveguide structure. When using a grounded coplanar waveguide equivalent to a quasi-grounded coplanar waveguide structure: Hv2=W+2S

[0047] Using the design formula of grounded coplanar waveguide, when The characteristic impedance Z of the side wal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com