Spartina Harvesting and Processing Machinery Ship and Spartina Grass Harvesting and Processing Method

A technology of processing machinery and rice grass, which is applied to harvesters, agricultural machinery and implements, cutters, etc., can solve the problems of high efficiency and processing of rice grass, and achieve the effects of improving the ecological environment of tidal flats, broadening market prospects, and suppressing flooding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described in detail below with reference to the drawings and specific embodiments.

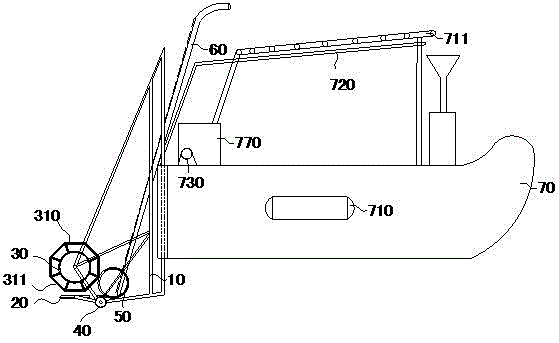

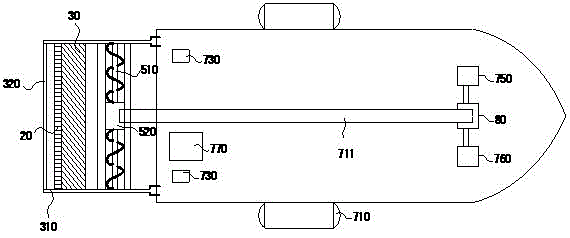

[0037] Such as Figure 1~2 As shown, a rice straw harvesting and processing machinery ship includes a frame 10 that can be raised and lowered. The bottom of the frame 10 is provided with a row of shears 20 for mowing. The buoyancy pick-up wheel of the row of shears, the buoyancy pick-up wheel includes the sealing roller 30 in the middle and the radiation support rods 310 arranged on the outer surface of the sealing roller 30 evenly distributed in the circumferential direction. The adjacent radiation support rods 310 are supported by radiation The rod connecting rods 311 are connected, and the radial struts 310 on both sides are connected by a cross rod 320. The two sides of the sealing drum 30 are connected with a rotating shaft driven by a motor. The sealing drum 30 is a hollow cylinder. Both sides of the sealing drum are provided with inlet and outl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com