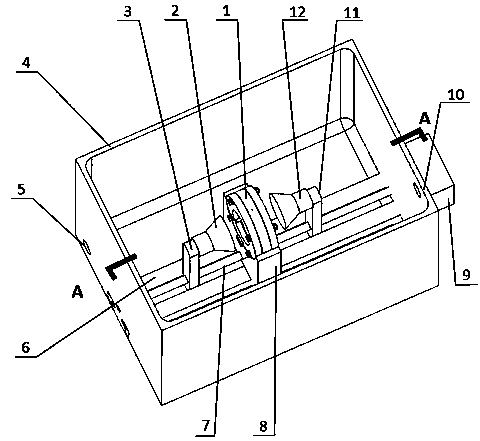

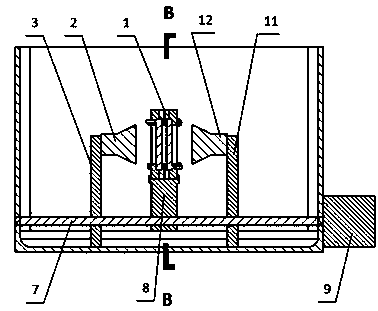

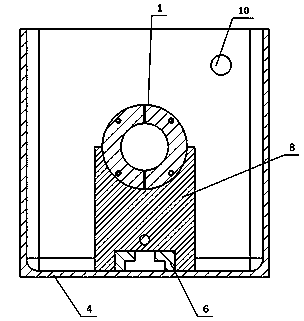

Liquid food sterilization device based on pulsed electric field and ultrasonic wave field

A technology of pulsed electric field and liquid food, applied in the directions of food ultrasonic treatment, food preservation, food electric treatment, etc., can solve the problems of increased cavitation threshold, lack of synergy, and reduced energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0028] The main parameters of the liquid food sterilization device based on pulsed electric field and ultrasonic field involved in the present invention are: the distance between the high-voltage electrode and the ground electrode is 5 mm, the radius of the effective treatment area is 25 mm, and the effective treatment capacity is about 9.8ml. The radius of the ultrasonic vibrator is 30 mm, the power of the ultrasonic ultrasonic generator is 0~50 W, the frequency is 20~25 kHz, the voltage of the output pulse of the high voltage pulse generator is 10~50 kV, the pulse width is 2~10 μs, and the frequency is 100~300Hz. Taking the device and method applied to the sterilization of Saccharomyces cerevisiae in Shaoxing rice wine as an example, the implementation of the device and method is further elaborated:

[0029] 1. Inject the pretreated Shaoxing rice wine containing Saccharomyces cerevisiae spores (initial temperature 20 ℃, conductivity 0.2 s / m) with a syringe through the bottom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com