Method for preparing medium-voltage tantalum powder with improved voltage resisting performance

A technology of tantalum powder and medium pressure, which is applied in the preparation of medium-pressure flake tantalum powder and the field of medium-pressure flake tantalum powder, which can solve the problems of difficult preparation and poor electrical performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

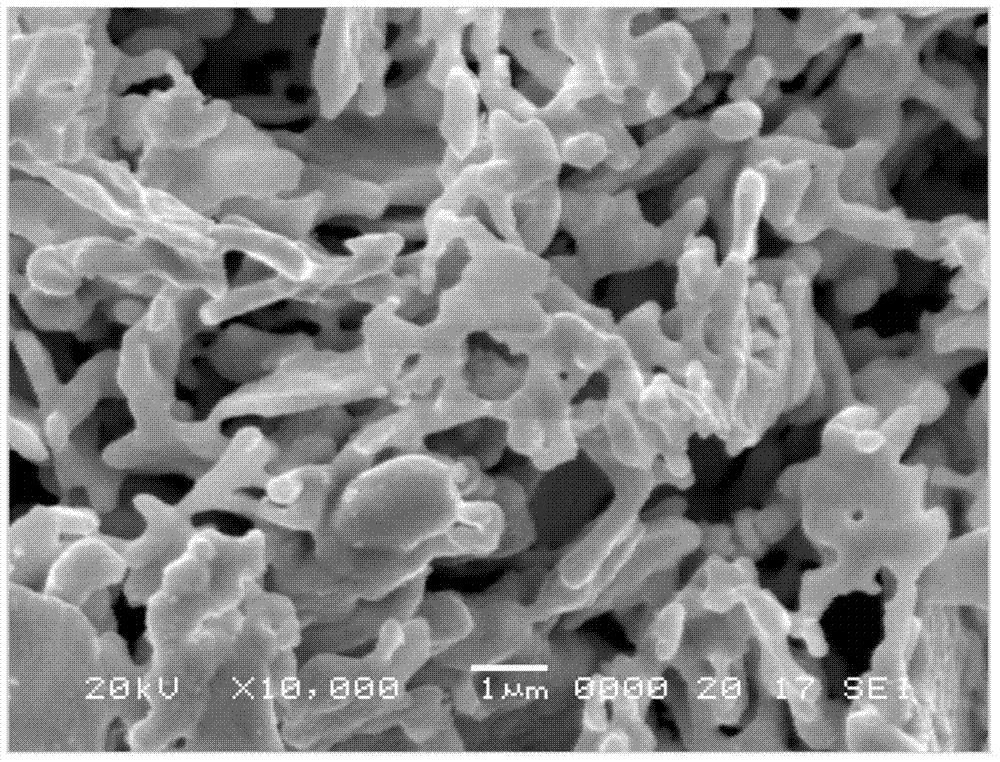

Embodiment 1

[0054] The tantalum powder after sodium reduction is selected as the raw material, and the main parameters are: O: 1800ppm, C: 20ppm, N: 150ppm, Fe: 15ppm. Use absolute ethanol as the ball milling medium, and select 30Kg of steel balls of ф3mm. Make sure that the ball mill bucket, mixing paddle and steel balls are rust-free and clean. The ball-to-material ratio is controlled at 6:1, and 5Kg of weighed tantalum powder is added into the ball mill bucket of the ball mill for ball milling. The ball mill speed is 80 rpm, and the ball milling time is 15 hours. Then filter the alcohol with suction and pickle according to the conventional pickling conditions. Pickling conditions: the first time: pickling with 10%HNO3+0.5%HF for 2 hours, soaking for 2 hours, pouring out the supernatant, the second time: the same as the first time, and the third time with 12%HNO3+0.7 Pickle with %HF+1%H2O2 for 2 hours, soak for 2 hours, finally pour out the supernatant, add enough water to rinse twice...

Embodiment 2

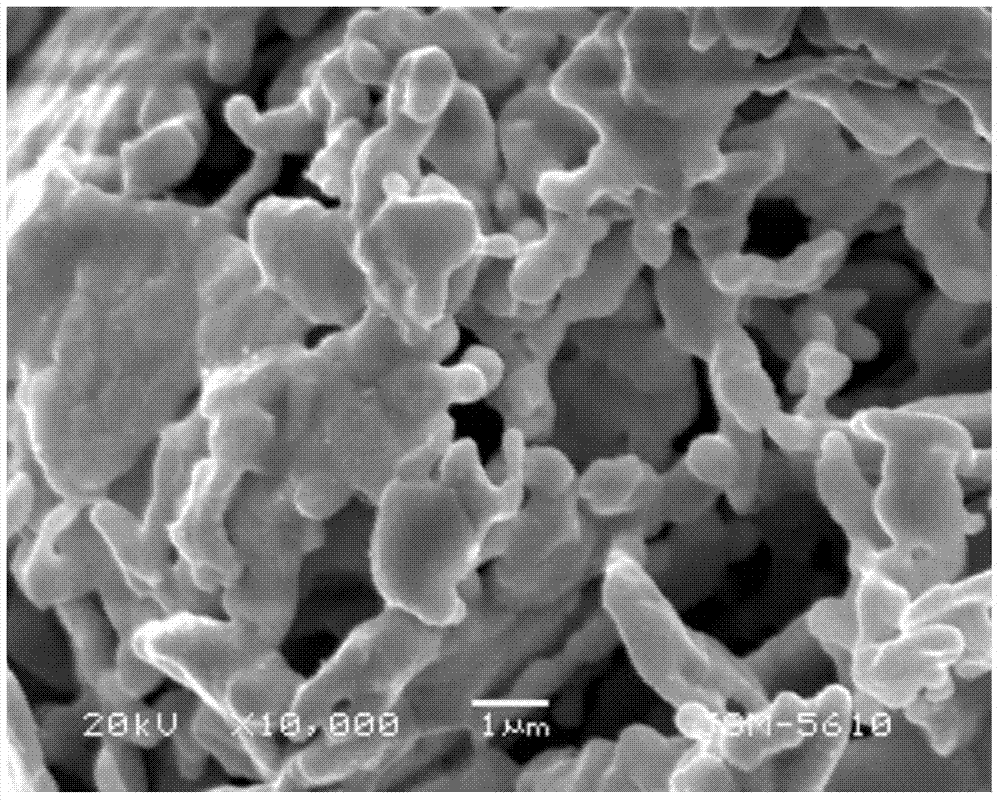

[0059]The tantalum powder after sodium reduction is selected as the raw material, and the main parameters are: O: 1800ppm, C: 20ppm, N: 150ppm, Fe: 15ppm. Use absolute ethanol as the ball milling medium, and select 30Kg of steel balls of ф3mm. Make sure that the ball mill bucket, mixing paddle and steel balls are rust-free and clean. The ball-to-material ratio is controlled at 6:1, and 5Kg of weighed tantalum powder is added into the ball mill bucket of the ball mill for ball milling. The ball mill speed is 80 rpm, and the ball milling time is 15 hours. Then filter the alcohol with suction and pickle according to the conventional pickling conditions. Pickling conditions: the first pass: with 10% HNO 3 + 0.5% HF pickling for 2 hours, soaking for 2 hours, and pouring out the supernatant. Second pass: Same as the first pass. Use 12%HNO for the third pass 3 +0.7%HF+2%H 2 o 2 Pickling for 2 hours, soaking for 2 hours, finally pour out the supernatant, add enough water to rin...

Embodiment 3

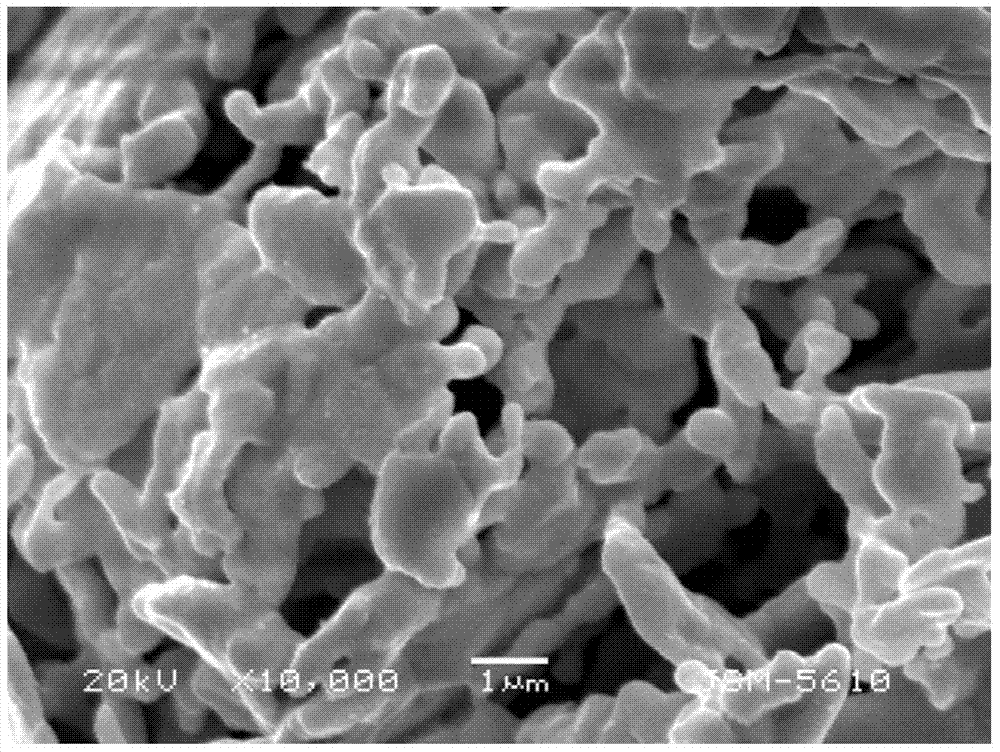

[0064] The tantalum powder after sodium reduction is selected as the raw material, and the main parameters are: O: 1800ppm, C: 20ppm, N: 150ppm, Fe: 15ppm. Use absolute ethanol as the ball milling medium, and select 30Kg of steel balls of ф3mm. Make sure that the ball mill bucket, mixing paddle and steel balls are rust-free and clean. The ball-to-material ratio is controlled at 6:1, and 5Kg of weighed tantalum powder is added into the ball mill bucket of the ball mill for ball milling. The ball mill speed is 80 rpm, and the ball milling time is 15 hours. Then filter the alcohol, pickle according to the conventional pickling conditions, pickling conditions: the first pass: use 10% HNO 3 + 0.5% HF pickling for 2 hours, soaking for 2 hours, and pouring out the supernatant. Second pass: Same as the first pass. Use 12%HNO for the third pass 3 +0.7%HF+2%H 2 o 2 Pickling for 2 hours, soaking for 2 hours, finally pour out the supernatant, add enough water to rinse twice, and add...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com