Method and device for preparing glyoxylic acid by multistage reaction

A technology of multi-stage reaction and glyoxylic acid, which is applied in the preparation of carboxylate, chemical instruments and methods, and the preparation of organic compounds, etc., can solve the problems of large amount of nitric acid used and generation of waste gas, etc., and achieve the reduction of waste gas production and waste gas The effect of reduced yield and stable reaction system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

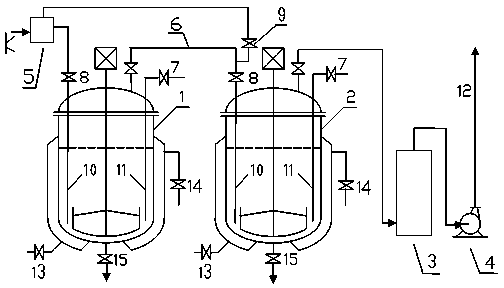

[0045] Correspondingly, the present invention also provides a device for preparing glyoxylic acid in the multistage reaction of the above-mentioned preparation method, comprising: a first reactor, a second reactor, a tail gas absorption tower and an induced draft fan connected in sequence; the first Both the reactor and the second reactor are provided with a jacket for containing steam or cooling water, and the first reactor and the second reactor are provided with a feed valve, an air inlet valve, and a jacket An upper port valve, a jacket lower port valve and a discharge valve; the first reactor and the second reactor are communicated through a waste gas conduit, and the device is also provided with the first reactor and the second reactor respectively. air filter connected to the air intake valve of the filter.

[0046] In a preferred version of the present invention, both the first reactor and the second reactor are provided with an air distributor and a liquid raw materia...

Embodiment 1

[0049] Embodiment 1 of the present invention provides a kind of device that multistage reaction prepares glyoxylic acid, as figure 1 As shown, the device includes: the first reactor 1, the second reactor 2, the tail gas absorption tower 3, the induced draft fan 4 and the air filter 5, wherein the first reactor 1, the second reactor 2, the tail gas absorption tower 3 and the induced draft fan 4 are connected sequentially, the first stage reaction is carried out in the first reactor 1, and the latter stage reaction is carried out in the second reactor 2; Or the jacket 16 of cooling water, when containing steam in the jacket 16, the reactor can be heated, when containing cooling water in the jacket 16, the reactor can be cooled; both on the first reactor 1 and the second reactor 2 A feed valve 7, an air inlet valve 8, a jacket upper valve 14, a jacket lower valve 13 and a discharge valve 15 are provided; the first reactor 1 and the second reactor 2 are communicated through a wast...

Embodiment 2

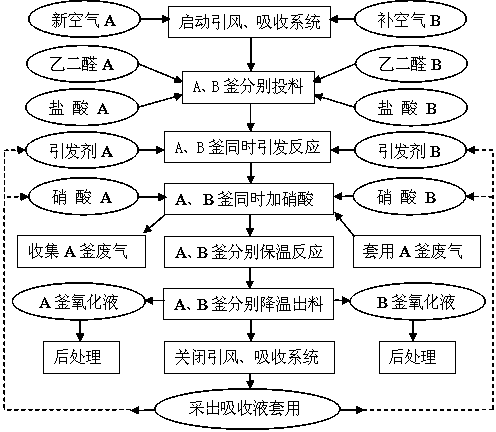

[0052] Example 2 of the present invention provides a method for preparing glyoxylic acid by multistage reaction, using the device in Example 1 to perform multistage preparation of glyoxylic acid, please refer to figure 2 As shown, the method includes:

[0053] (1) Start the induced draft and absorption system: open all the valves on the gas channel from the air filter 5 to the induced draft fan 4, start the induced draft fan 4 and the absorption liquid circulation pump of the tail gas absorption tower 3, so that the first reactor 1, the second reactor The series system composed of the second reactor 2, the tail gas absorption tower 3 and the induced draft fan 4 has air flow and generates a slight negative pressure (for example: -0.004MPa);

[0054] (2) The first reactor (A kettle) and the second reactor (B kettle) are fed separately: open the feed valve 7 of the first reactor 1, and put 2000kg of 40% glyoxal and 30% hydrochloric acid at one time 170kg; open the feed valve 7 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com