Silane cross-linked polyethylene insulating material with rated voltage 1kv and below

A polyethylene insulating material and silane cross-linking technology, which is applied in the direction of insulators, organic insulators, plastic/resin/wax insulators, etc., can solve problems such as limitations, and achieve the effects of improving uniformity, easy large-scale production, and tight combination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

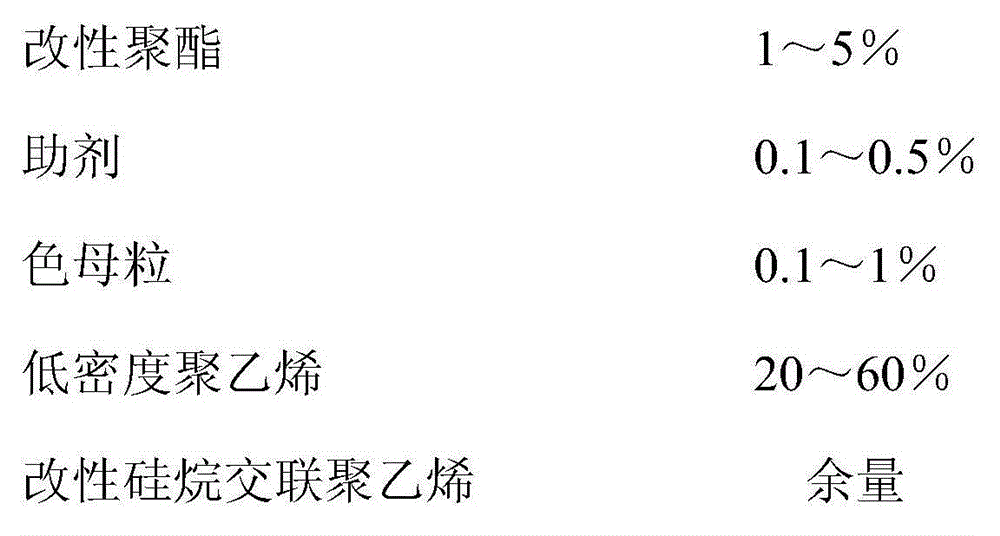

[0060] A silane cross-linked polyethylene insulating material with a rated voltage of 1kV or less, characterized in that the mass percentage of its raw materials is:

[0061]

[0062] The auxiliary agent is SAG compatibilizer, purchased from Nantong Rizhisheng Company.

[0063] The color masterbatch is a commercially available product, purchased from Shanghai Shengxia Chemical Co., Ltd.

[0064] The low-density polyethylene and silane cross-linked polyethylene are commercially available products.

[0065] The preparation method of described modified polyester, its concrete steps are:

[0066] (1) Disperse inorganic particles under the condition of methanol as a solvent, then add aminopropyltriethoxysilane under alkaline conditions, perform centrifugation after the reaction, and vacuum dry the solid to prepare surface functionalized inorganic particles;

[0067] The concentration of the inorganic particles in the alcohol solution is 5-35kg / m 3 , the pH of the system is co...

Embodiment 2

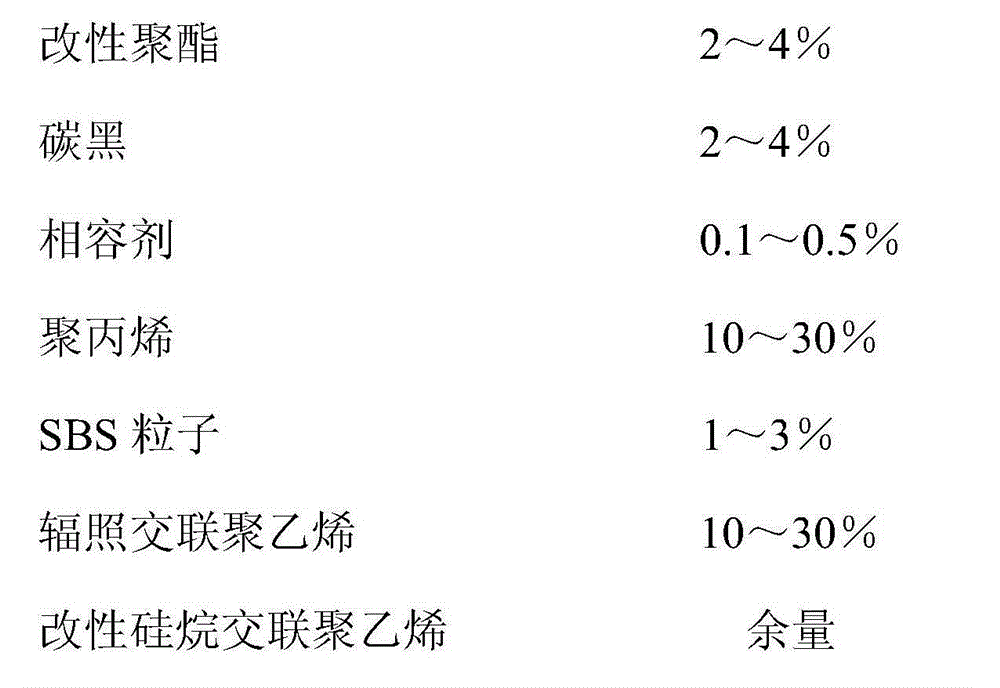

[0087] A silane cross-linked polyethylene insulating material with a rated voltage of 1kV or less, characterized in that the mass percentage of its raw materials is:

[0088]

[0089] The preparation method of described modified polyester, its concrete steps are:

[0090] (1) Disperse inorganic particles under the condition of methanol as a solvent, then add aminopropyltriethoxysilane under alkaline conditions, perform centrifugation after the reaction, and vacuum dry the solid to prepare surface functionalized inorganic particles;

[0091] The concentration of the inorganic particles in the alcohol solution is 5-35kg / m 3 , the pH of the system is controlled at 8.5-9.5, the reaction temperature is 60-75°C, and the reaction time is 150-240min;

[0092] The inorganic particles are nano-indium tin oxide, nano-indium antimony oxide and nano-titanium nitride particles, the mass ratio of the three is 1:1:2, the average particle size is 10-50nm, and ultrasonic dispersion is used ...

Embodiment 3

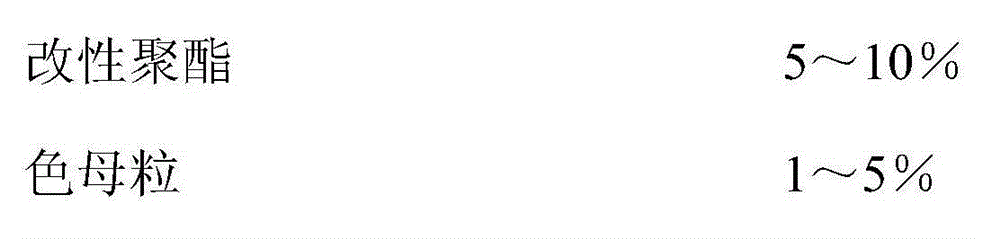

[0110] A silane cross-linked polyethylene insulating material with a rated voltage of 1kV or less, characterized in that the mass percentage of its raw materials is:

[0111]

[0112]

[0113] The preparation method of described modified polyester, its concrete steps are:

[0114] (1) Disperse inorganic particles under the condition of methanol as a solvent, then add aminopropyltriethoxysilane under alkaline conditions, perform centrifugation after the reaction, and vacuum dry the solid to prepare surface functionalized inorganic particles;

[0115] The concentration of the inorganic particles in the alcohol solution is 5-35kg / m 3 , the pH of the system is controlled at 8.5-9.5, the reaction temperature is 60-75°C, and the reaction time is 150-240min;

[0116] The inorganic particles are nano-indium tin oxide, nano-indium antimony oxide and nano-titanium nitride particles, the mass ratio of the three is 1:1:2, the average particle size is 10-50nm, and ultrasonic dispersio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com