Antiaging nano composite thermal-insulation paint and preparation method thereof

A nano-composite, heat-insulating coating technology, used in anti-corrosion coatings, coatings, etc., can solve the problems of yellowing, unsatisfactory barrier effect, unsatisfactory weather resistance, etc. Sexuality and the effect of general performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A kind of anti-aging nano composite thermal insulation coating, its composition and mass ratio are as follows,

[0040] Base material: TiO 2 / ZnO nanocomposite powder: nano ATO powder=100:0.7:1.5.

[0041]The base material includes: a monomer, an initiator, an active agent and an emulsifier, and the mass ratio of the monomer, the initiator, the active agent and the emulsifier is 100:1.5:1.1:1.3.

[0042] The monomer is composed of acrylic acid and n-butyl acrylate with a volume ratio of 2:3, the initiator is sodium dodecylbenzenesulfonate, and the emulsifier is OP-10.

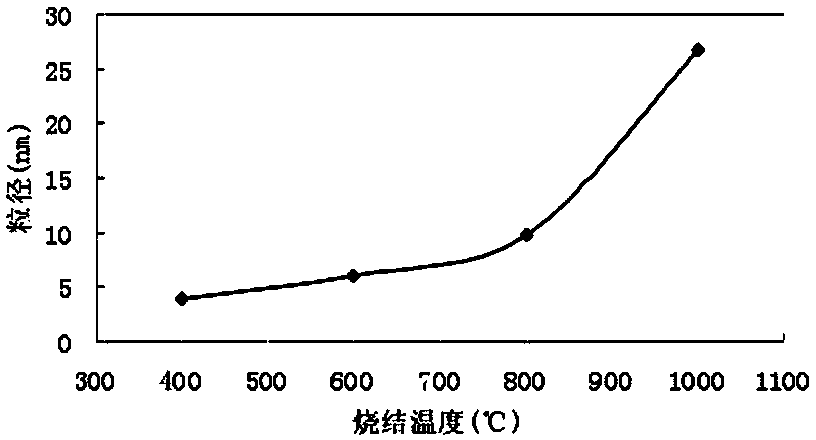

[0043] The TiO 2 / ZnO nanocomposite powder, TiO 2 : ZnO=10:7, the TiO 2 The particle size range of / ZnO nanocomposite powder is 40~70nm.

[0044] The particle size range of the nano-ATO powder is 20-70nm.

[0045] A preparation method of an anti-aging nano-composite thermal insulation coating, comprising the following steps;

[0046] Step (1), prepare base material:

[0047] (a), configure the mo...

Embodiment 2

[0063] A kind of anti-aging nano composite thermal insulation coating, its composition and mass ratio are as follows,

[0064] Base material: TiO 2 / ZnO nanocomposite powder: nano ATO powder=100:1.2:2.2.

[0065] The base material includes: a monomer, an initiator, an active agent and an emulsifier, and the mass ratio of the monomer, the initiator, the active agent and the emulsifier is 100:0.5:1.5:1.8.

[0066] The monomer is composed of acrylic acid and n-butyl acrylate with a volume ratio of 2:3, the initiator is sodium dodecylbenzenesulfonate, and the emulsifier is OP-10.

[0067] The TiO 2 / ZnO nanocomposite powder, TiO 2 : ZnO=10:5.8, the TiO 2 The particle size range of / ZnO nanocomposite powder is 40~70nm.

[0068] The particle size range of the nano-ATO powder is 20-70nm.

[0069] A preparation method of an anti-aging nano-composite thermal insulation coating, comprising the following steps;

[0070] Step (1), prepare base material:

[0071] (a), configure the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com