High strength boat deck with low-temperature strain aging brittleness resistant property and production method thereof

A strain-aging, ultra-high-strength technology, applied in ship or offshore platform structural steel, ultra-high-strength low-temperature marine steel plate and its manufacturing field, can solve problems such as inability to meet use requirements, reduce off-line heat treatment processes, and reduce production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

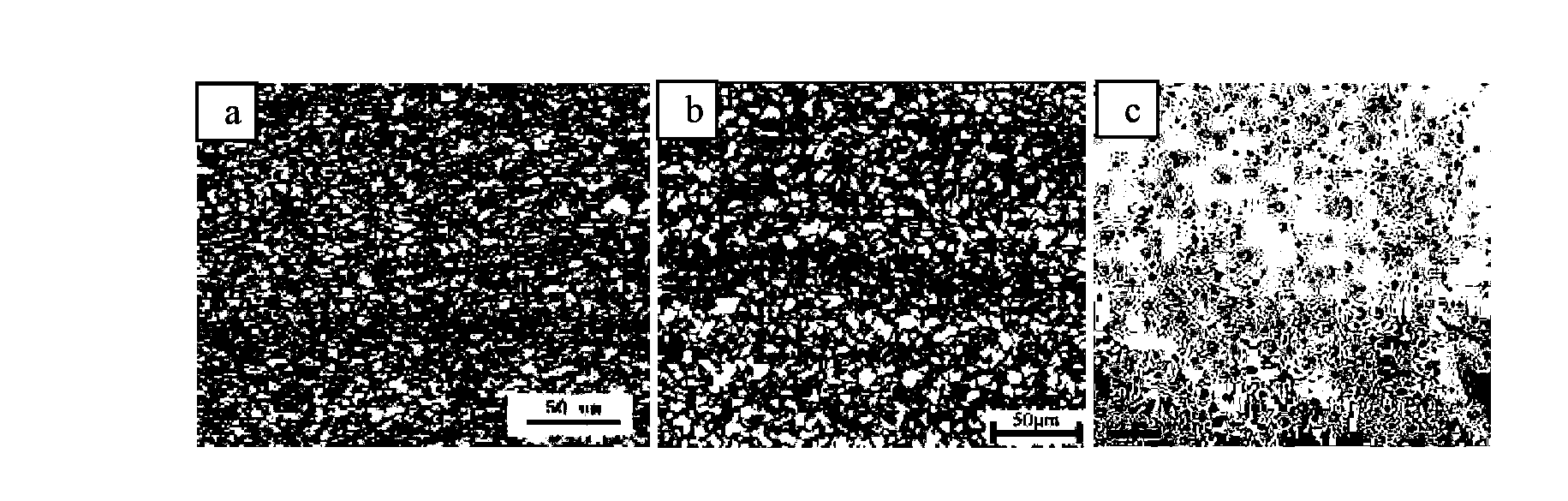

[0041] The metallographic microstructure and the precipitated morphology of two-phase particles in Example 2 before and after strain aging are shown in Figure 1 (a), (b) and (c). Figures (a) and (b) show the microstructure morphology before and after strain aging. Comparing the two figures, it can be seen that the composition of the microstructure is basically the same, both are ferrite + pearlite + a small amount of bainite, and the grain size is uniform. Small, these fine and uniform grain sizes increase the grain boundary area, increase the crack propagation path and crack propagation work, which can effectively inhibit the propagation of cracks; improve the cold crack resistance of the material. Figure (c) shows that under the controlled rolling and controlled cooling process, it can be seen that the two-phase particles in the inventive steel are fine and dispersed, and this precipitation behavior effectively reduces the solid solution of C and N atoms in the steel and thei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com