Optical component for passive coupling of chip array and parallel optical fiber and its assembly method

A chip array and optical component technology, applied in the coupling of optical waveguides, etc., can solve the problems of complex process and long time consumption, and achieve the effect of simple production process, short time consumption and easy realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

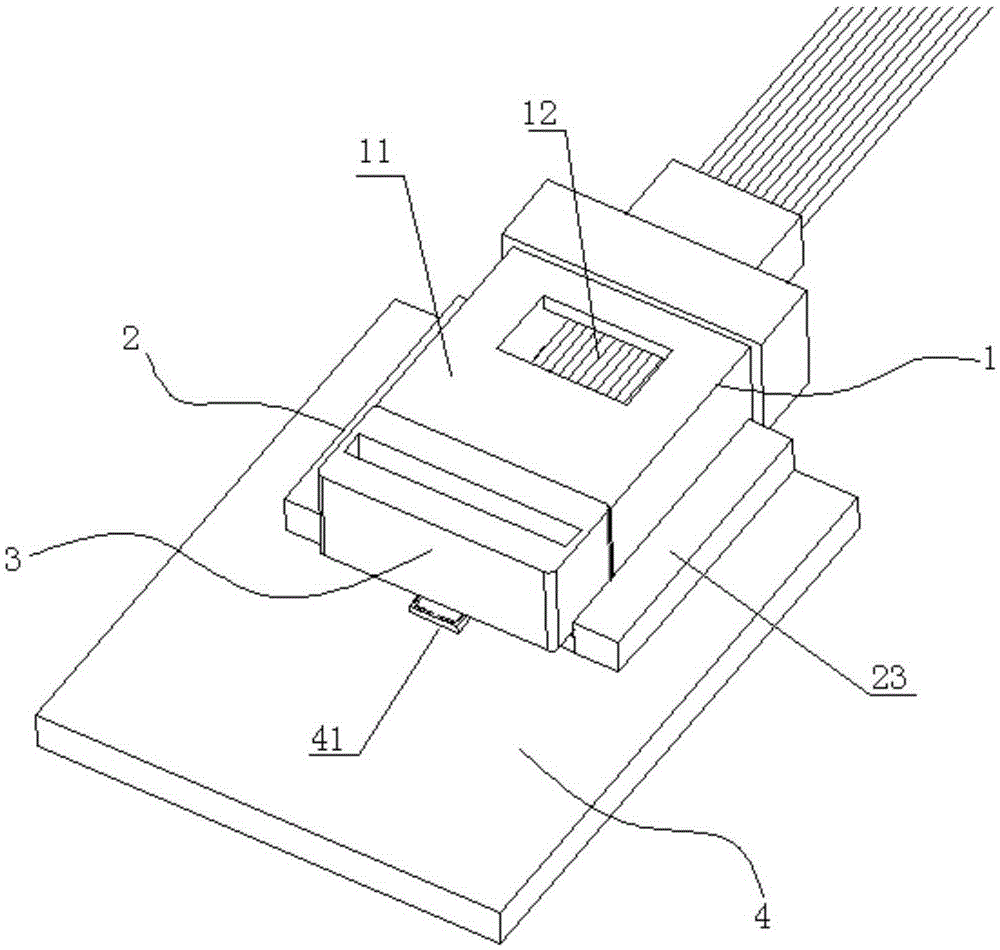

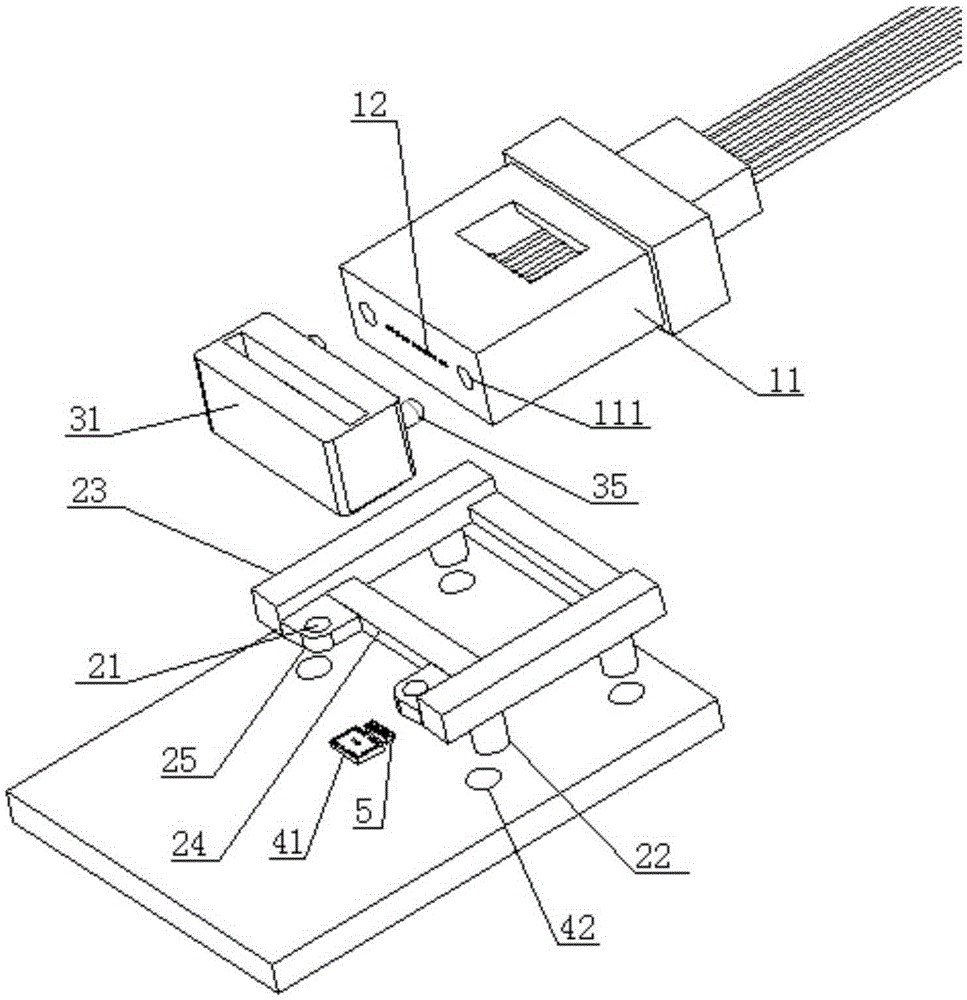

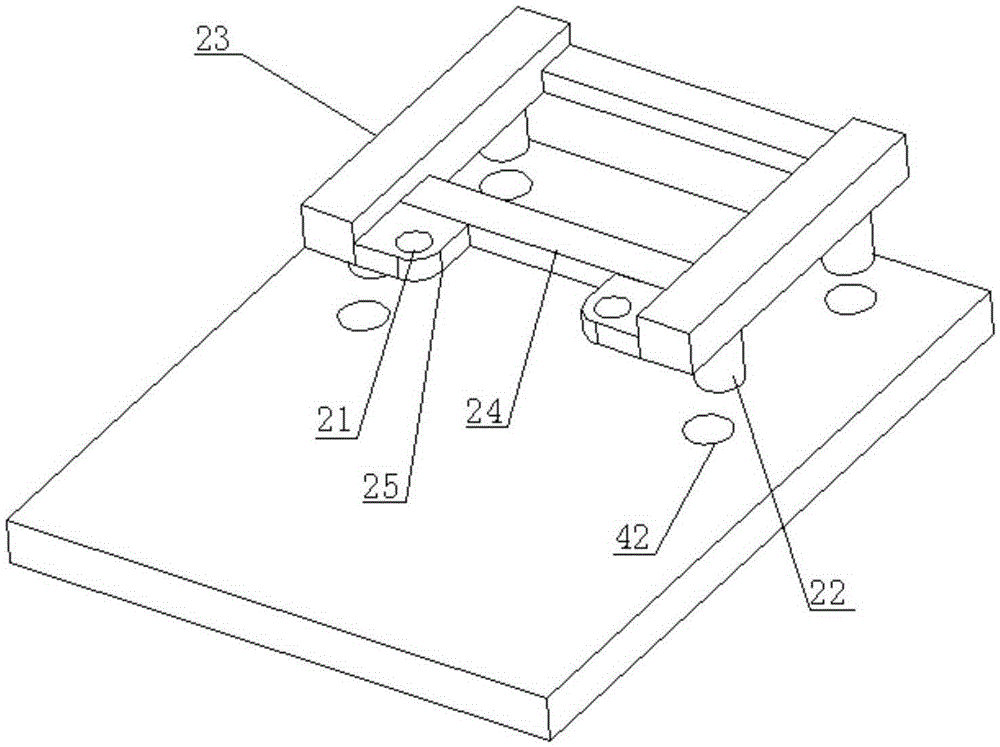

[0043] Such as figure 1 with figure 2 As shown, an optical assembly passively coupled between a chip array and parallel optical fibers includes an optical fiber array assembly 1, a coupling alignment positioning block 2, a lens array 3, a chip carrier 4, and at least one with a plurality of photoelectric conversion regions 51 (such as the light-emitting area of the VCSEL chip array or / and the photosensitive area of the PD chip array) the photoelectric chip array 5 (such as the VCSEL chip array or / and the PD chip array); Multiple parallel optical fibers 12 arranged in the fixed seat; the lens array includes a lens body 31, a second lens array surface 32 embedded in the lens body in the vertical direction corresponding to a plurality of photoelectric conversion regions, The first lens array surface 33 corresponding to the multi-channel parallel optical fiber embedded in the lens body in the horizontal direction and the first lens array surface 33 embedded in the lens body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com