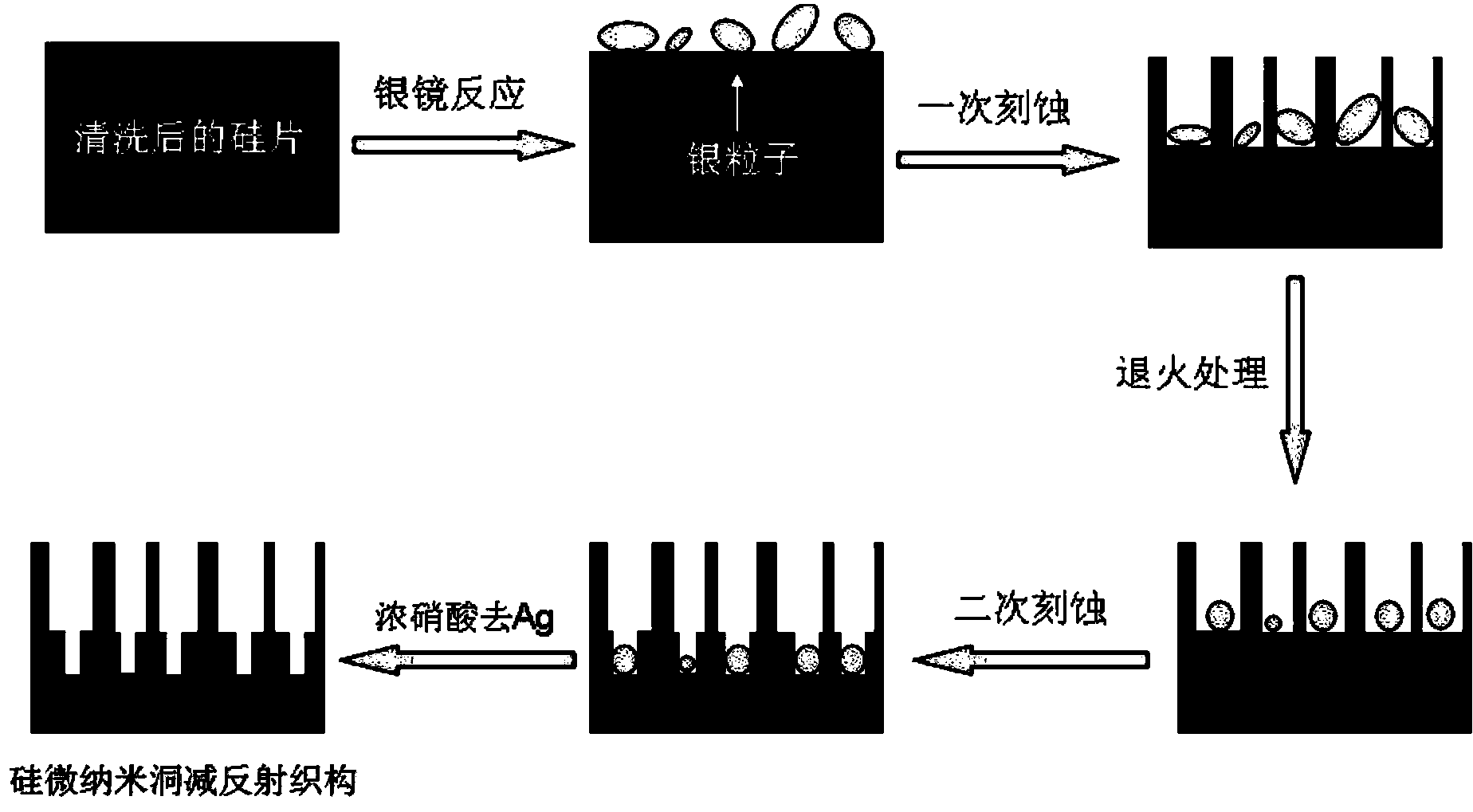

Preparation method of silicon micro-nano hole antireflection texture by utilizing silver nanoparticles to assist secondary etching

A technology of silver nanoparticles and nano-silver particles, which is applied in the direction of final product manufacturing, sustainable manufacturing/processing, electrical components, etc., can solve the problem of single shape, achieve the effect of optimizing the etching structure and improving the effect of anti-reflection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 1. If figure 1 As shown, at room temperature, the monocrystalline silicon wafer was cleaned with acetone and ethanol for 10 minutes, and then washed with H 2 o 2 with H 2 SO 4 、H 2 The mixed liquid with O volume ratio of 1:3:5 was ultrasonically cleaned for 10 minutes, then rinsed with deionized water and dried with nitrogen gas.

[0030] 2. Immerse the single crystal silicon wafer cleaned in step 1 into AgNO 3 , NaOH, NH 3 ·H 2 In the mixed solution of O, glucose and deionized water, AgNO in the mixed solution 3 The concentration of NaOH is 0.05mol / L, the concentration of NaOH is 0.2mol / L, NH 3 ·H 2 The concentration of O was 1 mol / L, the concentration of glucose was 0.005 mol / L, and the silicon wafer was bathed in 60°C water bath for 4 minutes, so that the surface of the silicon wafer was evenly coated with a layer of nano-silver particles.

[0031] 3. Put the single crystal silicon wafer after silver plating in step 2 into HF10%, H 2 o 2 15%, deionized wa...

Embodiment 2

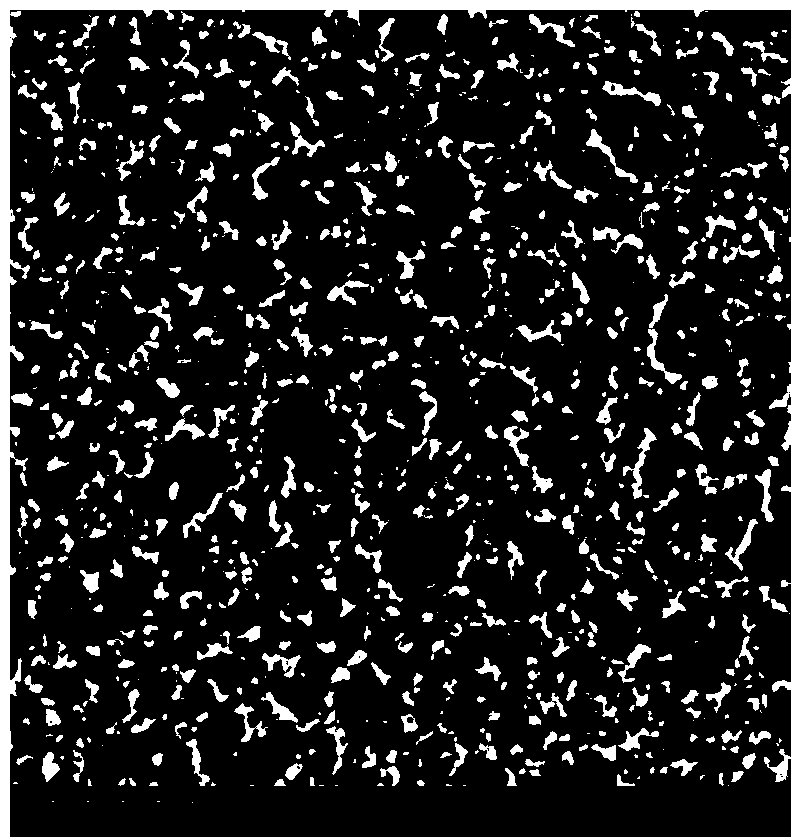

[0041] In step 4 of this embodiment, the monocrystalline silicon wafer etched for the first time is placed in a nitrogen atmosphere, heated to 300° C., kept at a constant temperature for 60 minutes, and then naturally cooled to room temperature. The other steps are the same as in Example 1 to obtain the silicon micro-nano hole anti-reflection texture (see image 3 ).

Embodiment 3

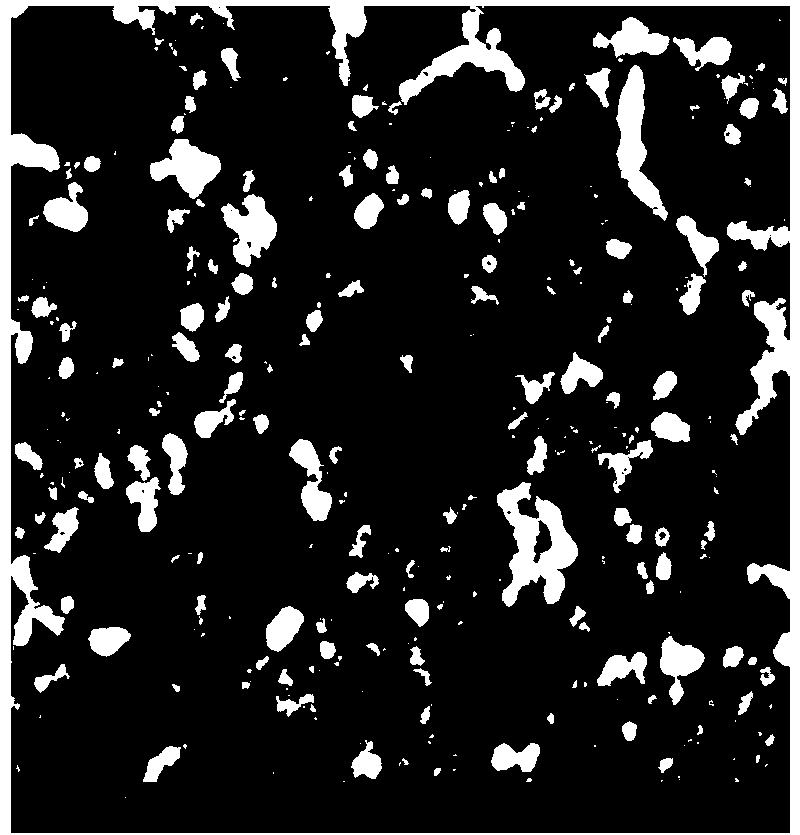

[0043] In Step 4 of this embodiment, the monocrystalline silicon wafer etched for the first time is placed in a nitrogen atmosphere, heated to 500° C., kept at a constant temperature for 60 minutes, and then naturally cooled to room temperature. The other steps are the same as in Example 1 to obtain the silicon micro-nano hole anti-reflection texture (see Figure 4 ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com