M1 + M2/C catalyst and its preparation method

A catalyst, C1-C3 technology, used in physical/chemical process catalysts, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc. The effect of catalytic activity, high activity, and simple and easy preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

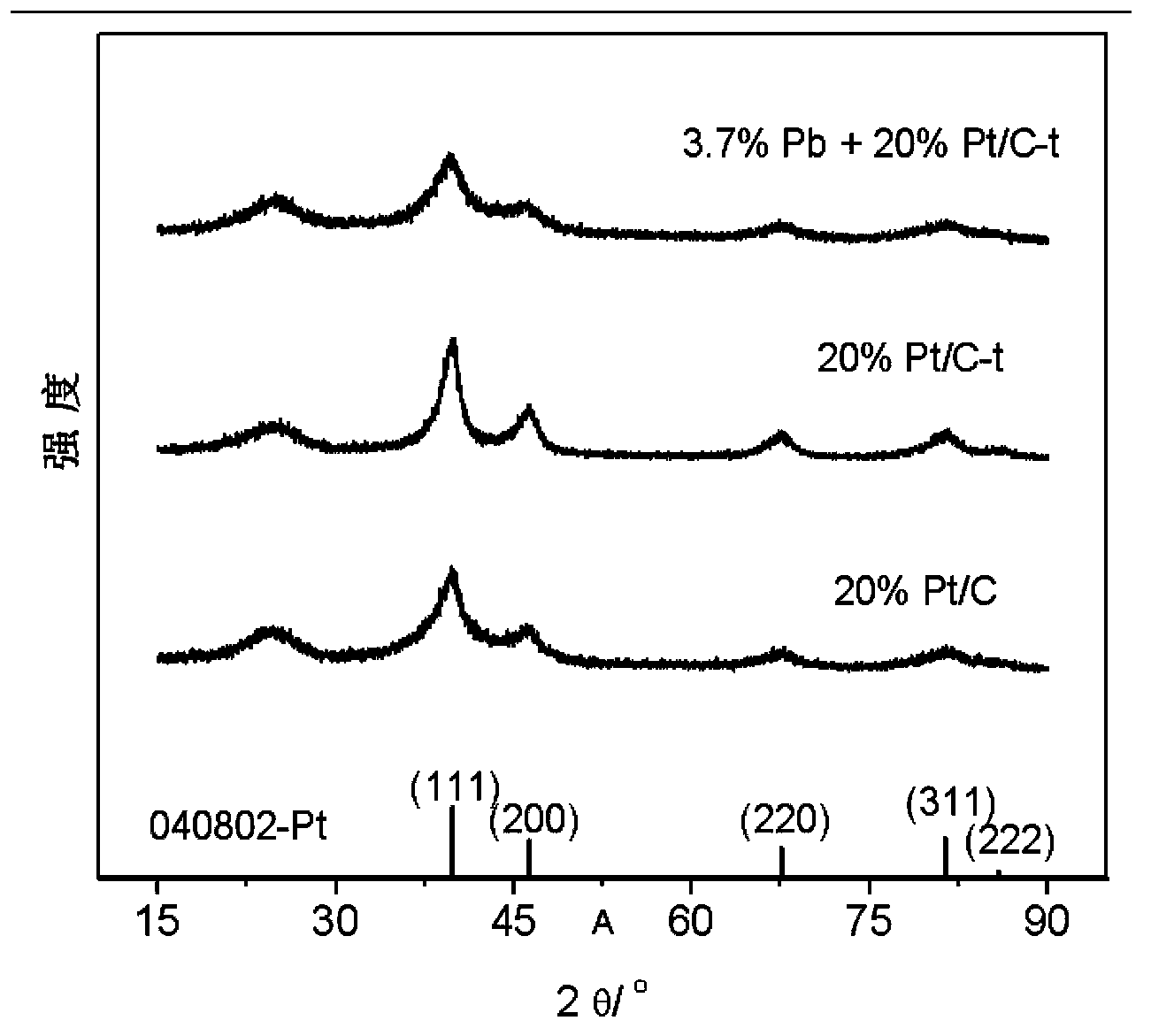

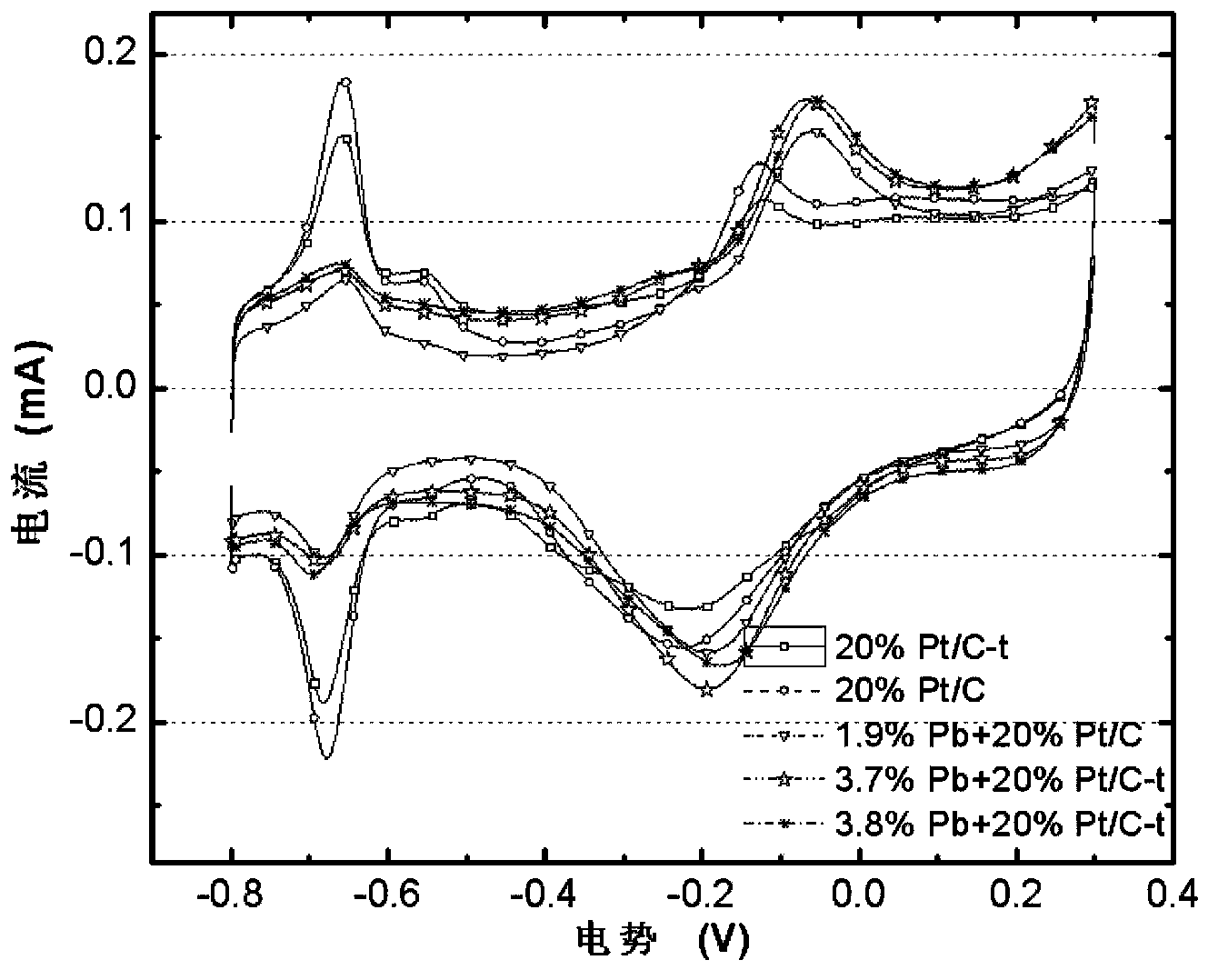

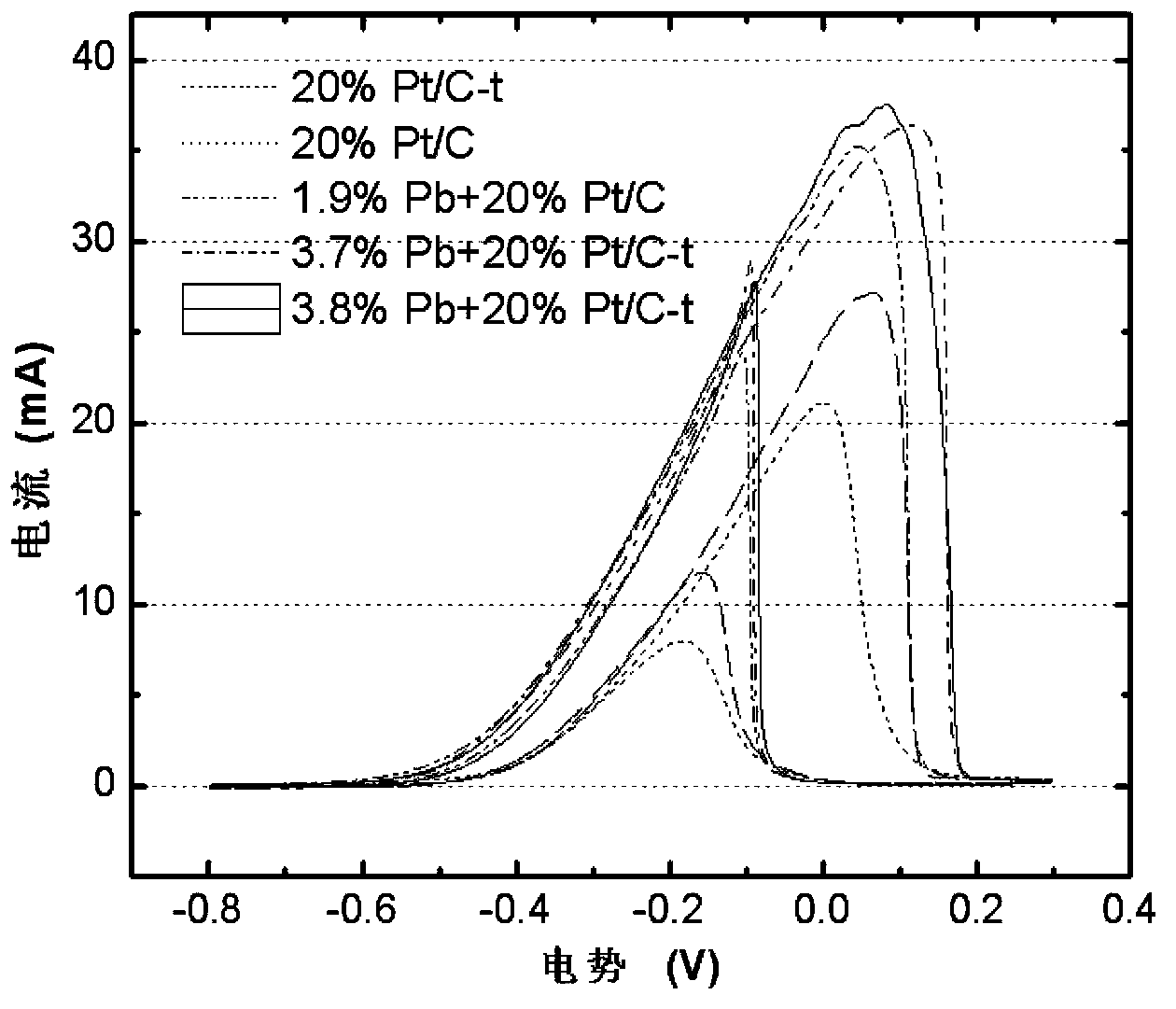

[0034] Example 1: 1.9%Pb+20%Pt / C (1.9% means that the mass content of active component Pb is 1.9%, 20% means that the mass content of active component Pt is 20%, C means Vulcan XC- 72)

[0035] First, 100 mg of 20% Pt / C was ultrasonically dispersed in 20 mL of high-purity water, and then 20 mL of Pb(CH 3 COO) 2 In aqueous solution, dispersed evenly. The above solution was soaked and stirred at room temperature for 4 h, filtered, washed with 80 mL of water, and then dried in an air atmosphere at 90° C. to remove the solvent to obtain a black powder. The above black powder was ground and weighed, and the target product was 1.9%Pb+20%Pt / C electrocatalyst.

Embodiment 2

[0036] Example 2: 3.8%Pb+20%Pt / C-t (3.8% means that the mass content of active component Pb is 3.8%, 20% means that the mass content of active component Pt is 20%, C-t means Vulcan XC- 72 with 5MHNO 3 The solution was refluxed at 110°C for 6h and then washed and dried to obtain the carrier)

[0037] First, 80 mg of 20% Pt / C-t was ultrasonically dispersed in 16 mL of high-purity water, and then 16 mL of Pb(CH 3 COO) 2 In aqueous solution, dispersed evenly. The above solution was immersed and stirred at room temperature for 4 h, filtered, washed with 62 mL of water, and then dried in an air atmosphere at 90° C. to remove the solvent to obtain a black powder. The above black powder was ground and weighed, and the target product was 3.8%Pb+20%Pt / C-t electrocatalyst.

Embodiment 3

[0038] Example 3: 3.7%Pb+20%Pt / C-t (3.7% means that the mass content of active component Pb is 3.8%, 20% means that the mass content of active component Pt is 20%, C-t means Vulcan XC- 72 with 5MHNO 3 The solution was refluxed at 110°C for 6h and then washed and dried to obtain the carrier)

[0039] First, 161 mg of 20% Pt / C-t was ultrasonically dispersed in 32 mL of high-purity water, and then 32 mL of Pb(CH 3 COO) 2 In aqueous solution, dispersed evenly. The above solution was immersed and stirred at room temperature for 4 h, filtered, washed with 128 mL of water, and then dried in an air atmosphere at 90° C. to remove the solvent to obtain a black powder. The above black powder was ground and weighed, and the target product was 3.7%Pb+20%Pt / C-t electrocatalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com