Laminated high-gain circular polarization micro-strip array antenna based on LTCC

A microstrip array, circular polarization technology, applied in the direction of antenna, antenna array, radiating element structure, etc., can solve the development needs of the unfavorable microstrip patch antenna and the miniaturization of the carrier conformal design, and cannot take into account the circular polarization. and gain characteristics, reducing the mechanical strength of the antenna, etc., to avoid the output mismatch in the input domain, reduce the phase and amplitude errors, and improve the stability and reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below with reference to the accompanying drawings and specific examples, but the embodiments of the present invention are not limited thereto.

[0025] Such as Figure 6 , Figure 7 As shown, the center frequency point of the microstrip patch antenna provided by the embodiment of the present invention is 10.3 GHz, which is a common antenna for transmitting and receiving of the microstrip patch. The present invention can realize a microstrip patch antenna with an impedance bandwidth exceeding 560 MHz, and the antenna gain can reach 22.10dBi, and the axial ratio of the antenna can reach 1.77dB.

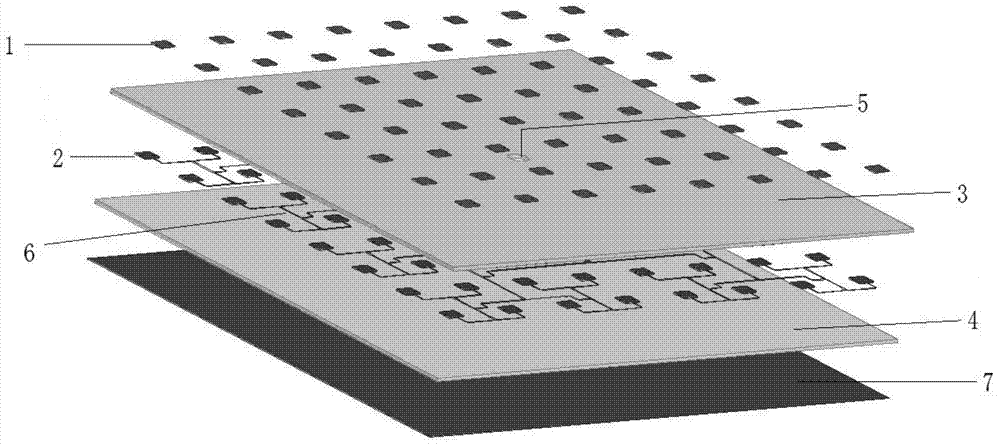

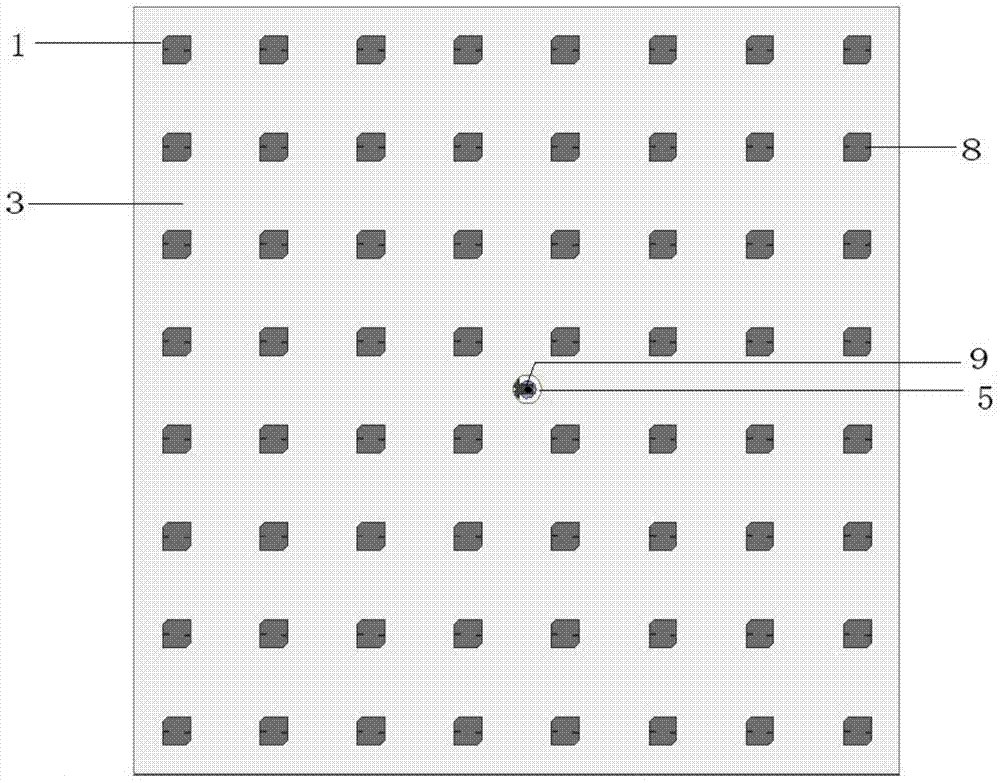

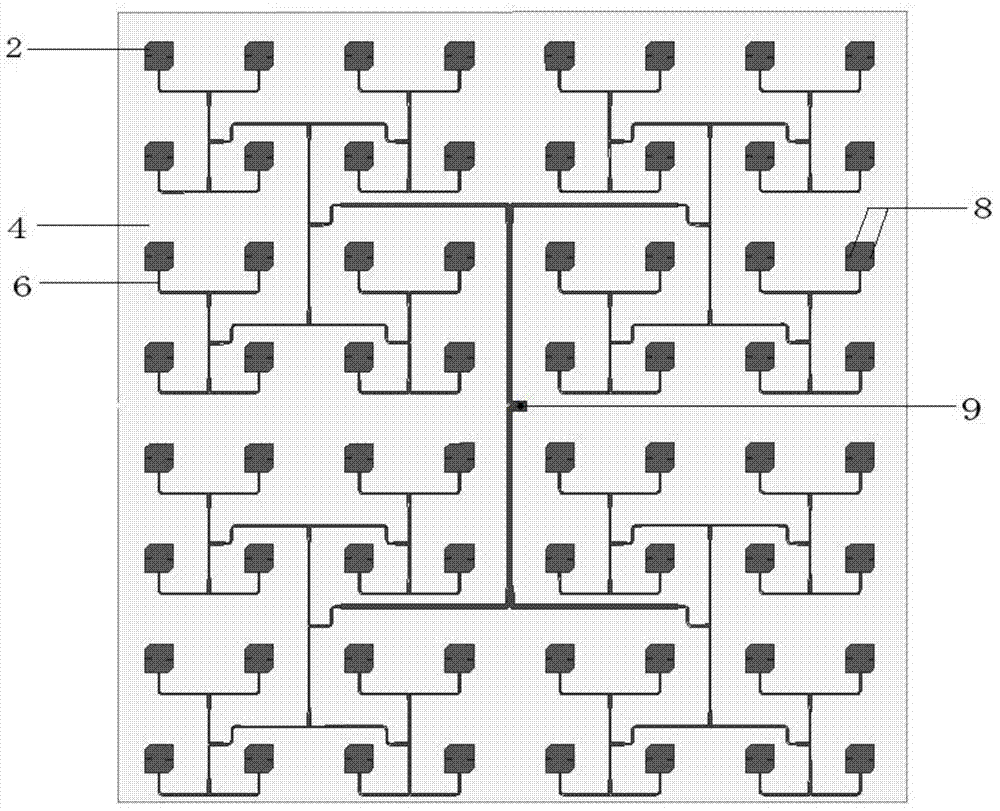

[0026] A LTCC stacked circularly polarized microstrip array antenna provided in this embodiment has a structure such as Figure 1 to Figure 5 shown, including:

[0027] Lower dielectric substrate: The substrate is made of five LTCC cast film sheets with a thickness of 0.1mm and a dielectric constant of 5.9. The lower su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com