Electric injection surface plasma micro-nano structure waveguide output laser source of coplanar electrode

A surface plasmon, coplanar electrode technology, applied in phonon exciters, circuits, electrical components, etc., can solve problems such as external

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

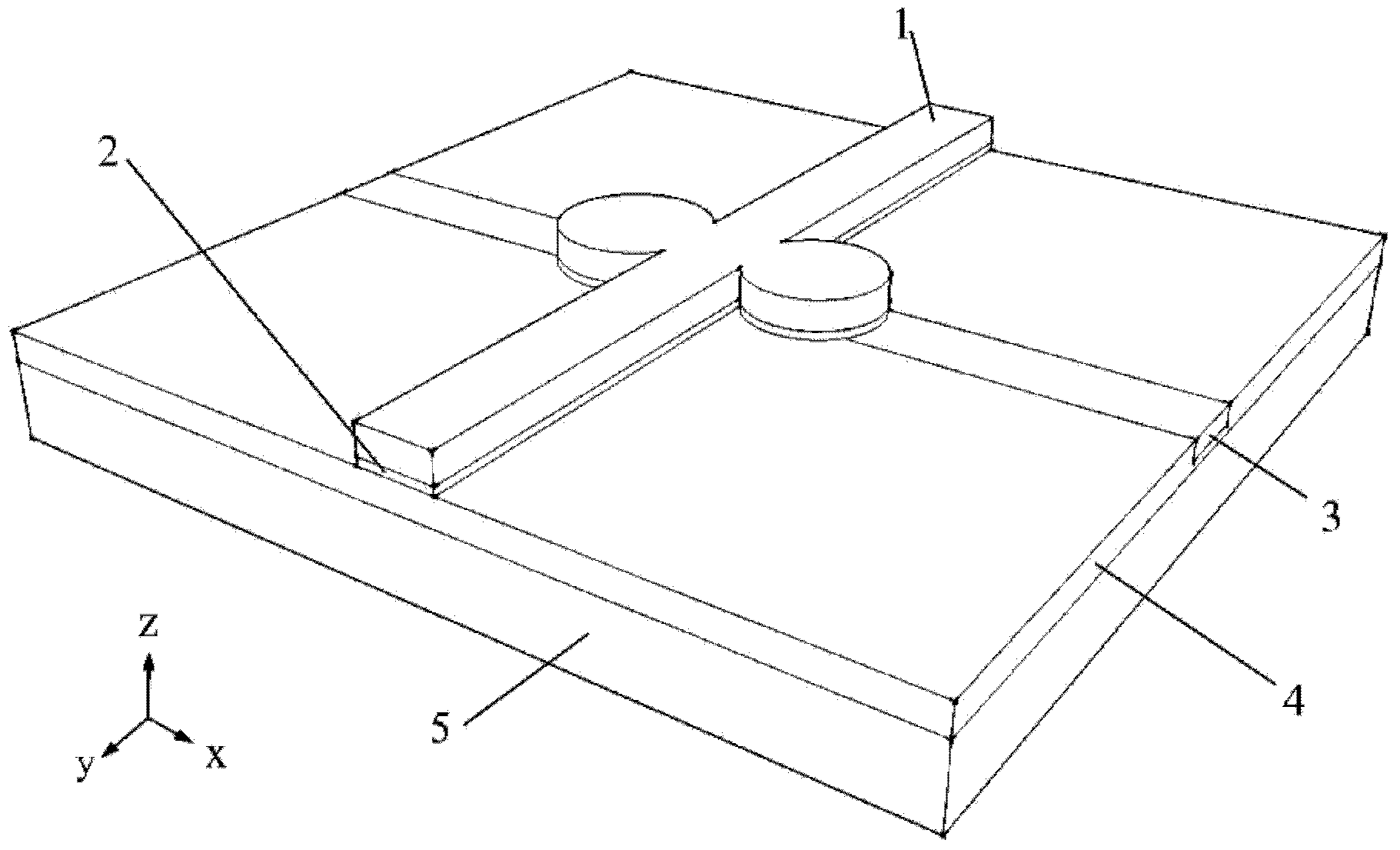

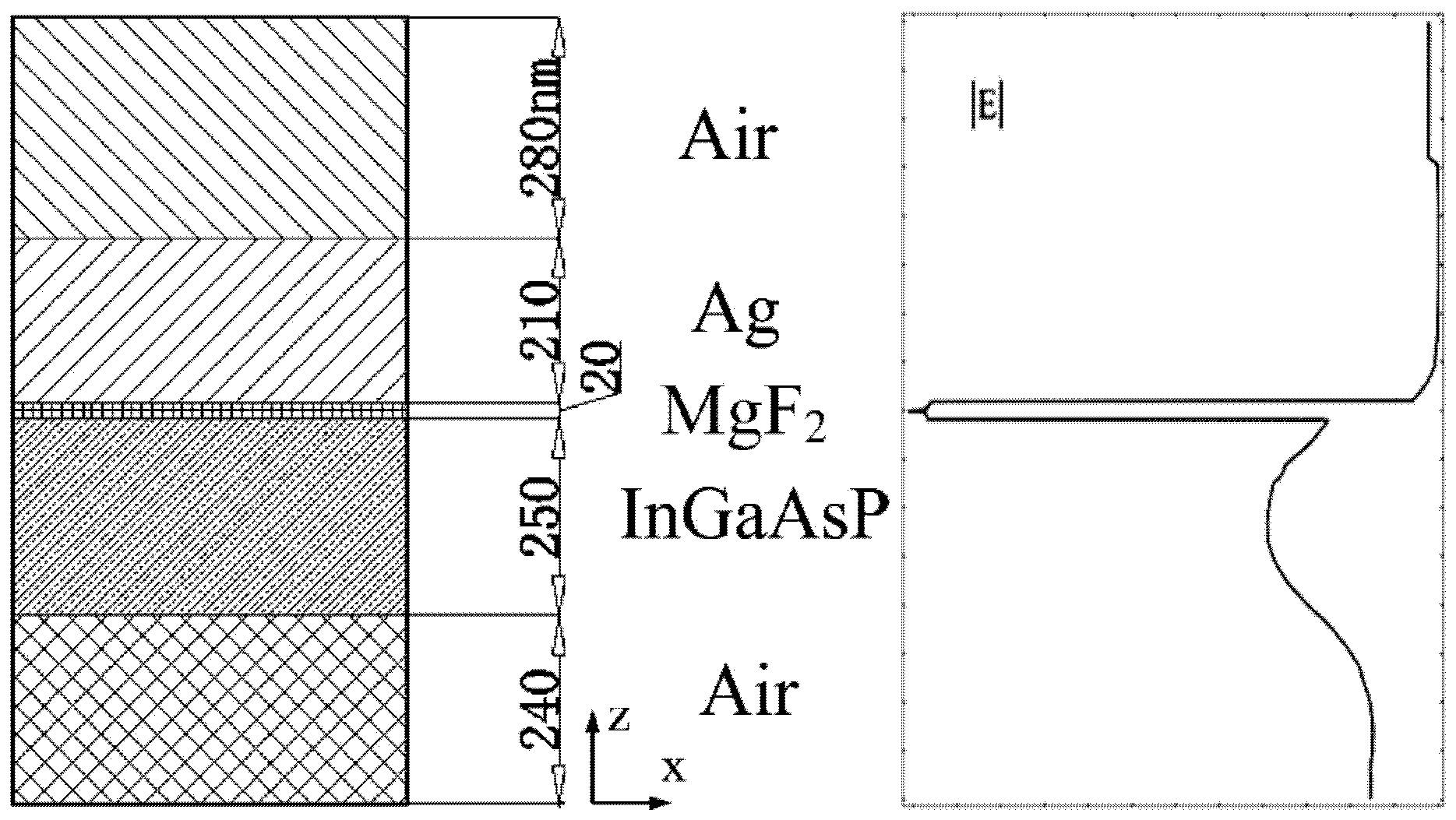

[0037] In this embodiment, the semiconductor active material and the two circular ion implantation regions adopt InGaAsP multiple quantum well material with a refractive index of 3.3, a thickness of 205nm and a waveguide width of 1500nm; the metal is Ag with a refractive index of 0.514-10.8i, and the The thickness is 250nm, the width of the silver strip is 1500nm; the insulating layer is MgF 2 The refractive index is 1.38 and the thickness is 20nm.

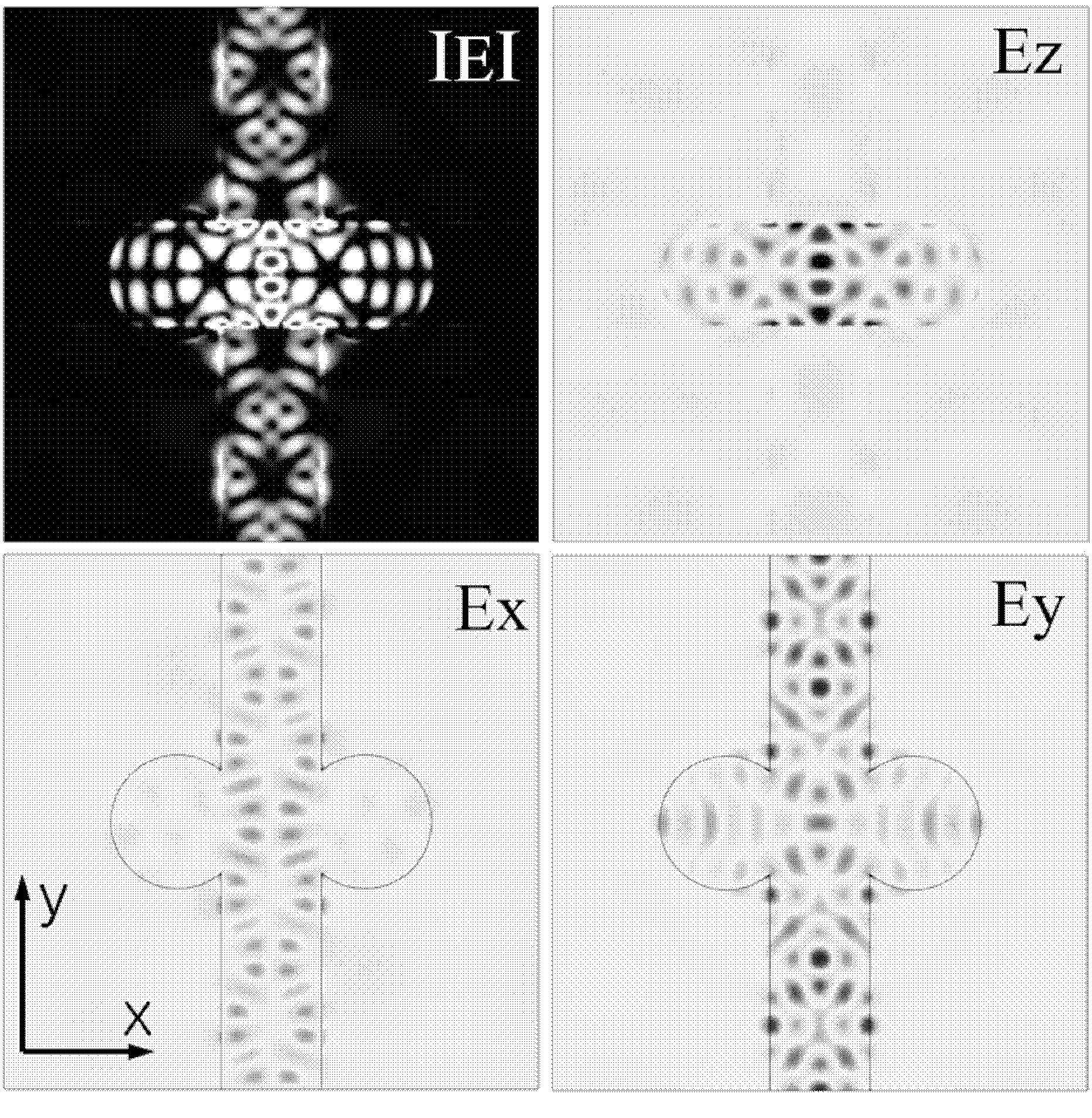

[0038] In this example, the COMOSL3D Eigenfrequency module is used for simulation experiments. Here we use air instead of figure 1 Middle area 4 and 5, in order to simplify the calculation amount of the simulation experiment, the parameters are set as above. The electric field along the depth Z direction in the subwavelength cavity is strongly confined to 20nm MgF 2 layer, such as figure 2 As shown, surface plasmon resonance is formed. The distribution of the electric field and its components in the simulation results is as f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com